All-hydraulic automatic drilling tool conveying device for deep-well drilling rig

A deep well drilling rig, full hydraulic technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of large size of power catwalk structure, difficulty in connecting and unloading pipe strings, affecting the stability of the whole machine, etc., to achieve Prevent the drill pipe from falling and hurting people, facilitate transportation, and push the reciprocating motion to have an efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

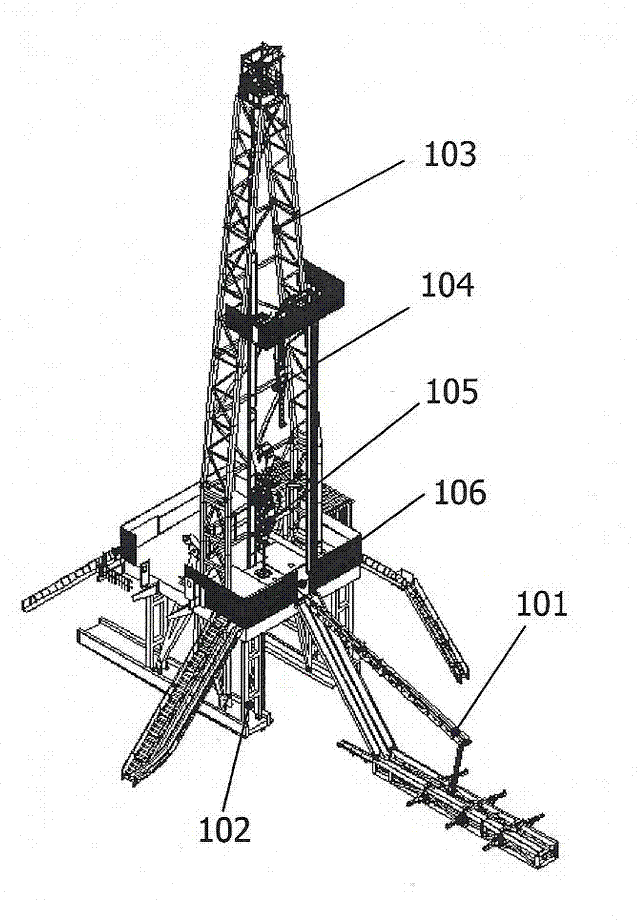

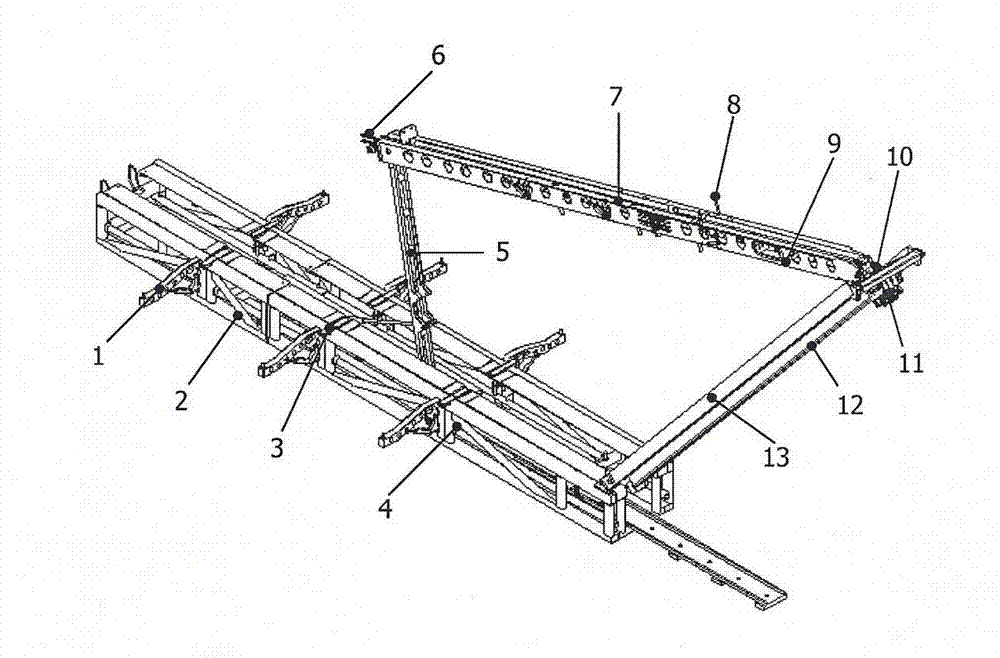

[0027] see Figure 1 to Figure 12 As shown, the present invention is composed of a drill pipe support 1, a platform 2, a turnover mechanism 3, a slideway luffing mechanism 4, a strut mechanism 5, a drill pipe push mechanism 6, a drill pipe ejection mechanism 7, an anti-fall mechanism 8, Lifting slideway 9, angle-changing mechanism 10, lifting tackle 11, chain 12 and ramp 13 form.

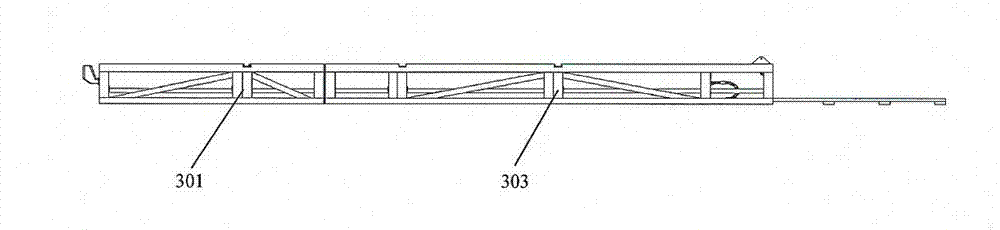

[0028] Platform 2 uses a two-stage approach, such as Figure 4 As shown, the front platform 303 and the rear platform 301 are connected by a positioning pin 302, and the platform 2 adopts a truss structure, which has a strong structural bearing capacity and can be disassembled for convenient transportation.

[0029] Lifting slideway 9 is divided into front and rear two sections, as Figure 5 As shown, the front lift slideway 401 is connected to the rear lift slideway 403 through bolts 402 . A drill pipe pushing mechanism 6, a drill pipe ejecting mechanism 7, and an anti-fall mechanism 8 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com