Blade-type energy recovery shock absorber

A technology of energy recovery and shock absorber, which is applied in the direction of spring/shock absorber, machine/engine, vibration suppression adjustment, etc. It can solve the problems of low efficiency of the energy feeding system, inferior to passive suspension, and the influence of the internal clearance of the transmission system, etc. , to achieve high energy recovery efficiency, improve driving comfort, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but is not limited to the content described below.

[0030] The vane type energy recovery shock absorber provided by the present invention is based on the traditional tracked vehicle vane type shock absorber, plus a set of energy recovery mechanism, which can increase energy feedback function and damping force control without changing the original vehicle structure function to improve the fuel economy and ride comfort of tracked vehicles.

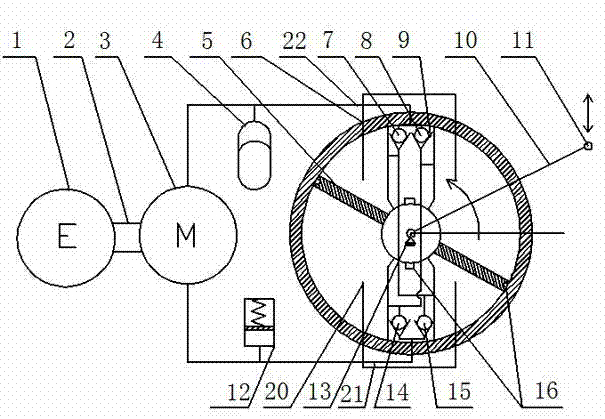

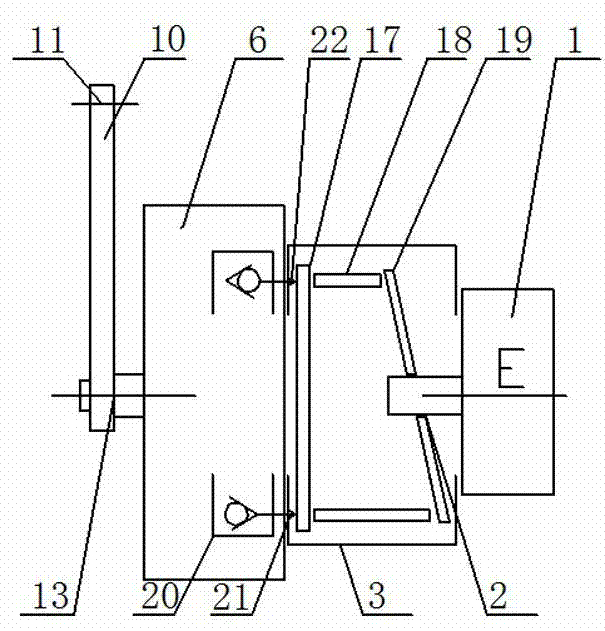

[0031] The energy recovery mechanism such as figure 1 and figure 2 As shown, it includes a generator 1 , a hydraulic motor 3 , a hydraulic circuit system 20 , an airbag accumulator 4 , and a mechanical accumulator 12 . This special tracked vehicle shock absorber can convert the linear motion between the sprung mass and the unsprung mass of the suspension system caused by uneven ground into a hydraulic flow that does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com