Insulation self-lubrication sliding plate

A self-lubricating, self-lubricating column technology, applied in the direction of engine lubrication, bearing components, engine components, etc., can solve problems such as safety hazards and skateboard insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

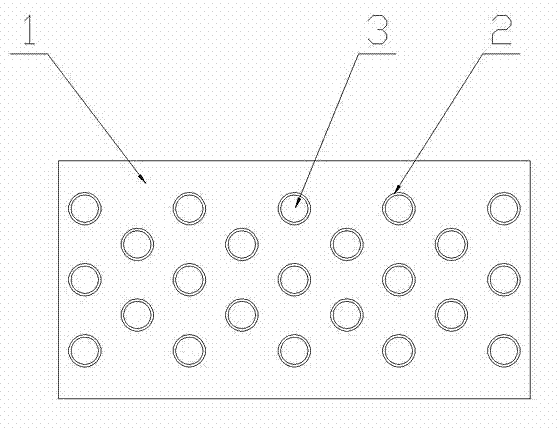

[0010] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: an insulating self-lubricating skateboard, this skateboard includes a bakelite substrate 1 as a base, a plurality of counterbores 2 are evenly distributed on the surface of the bakelite substrate 1, each counterbore 2 is embedded with a solid self-lubricating Column 3, this solid self-lubricating column 3 is made of graphite powder and industrial paraffin, and the quality of graphite powder is 2.5 to 3 times the mass of industrial paraffin.

[0011] The insulating self-lubricating slide plate of the embodiment of the present invention adopts bakelite as the material of the substrate. Since bakelite has high mechanical strength, toughness, wear resistance, stable size, corrosion resistance and other characteristics, especially its excellent electrical insulation performance, bakelite is used as the substrate. It can not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com