Three-dimensional oligodynamic convection heat transferring LED (light emitting diode) lamp

A technology of LED lamps and micro power, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of narrow internal space of LED lamps, attenuation of LED light source chip life, ventilation and heat dissipation Poor performance and other problems, to achieve good heat dissipation effect, small external restrictions, and improve structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

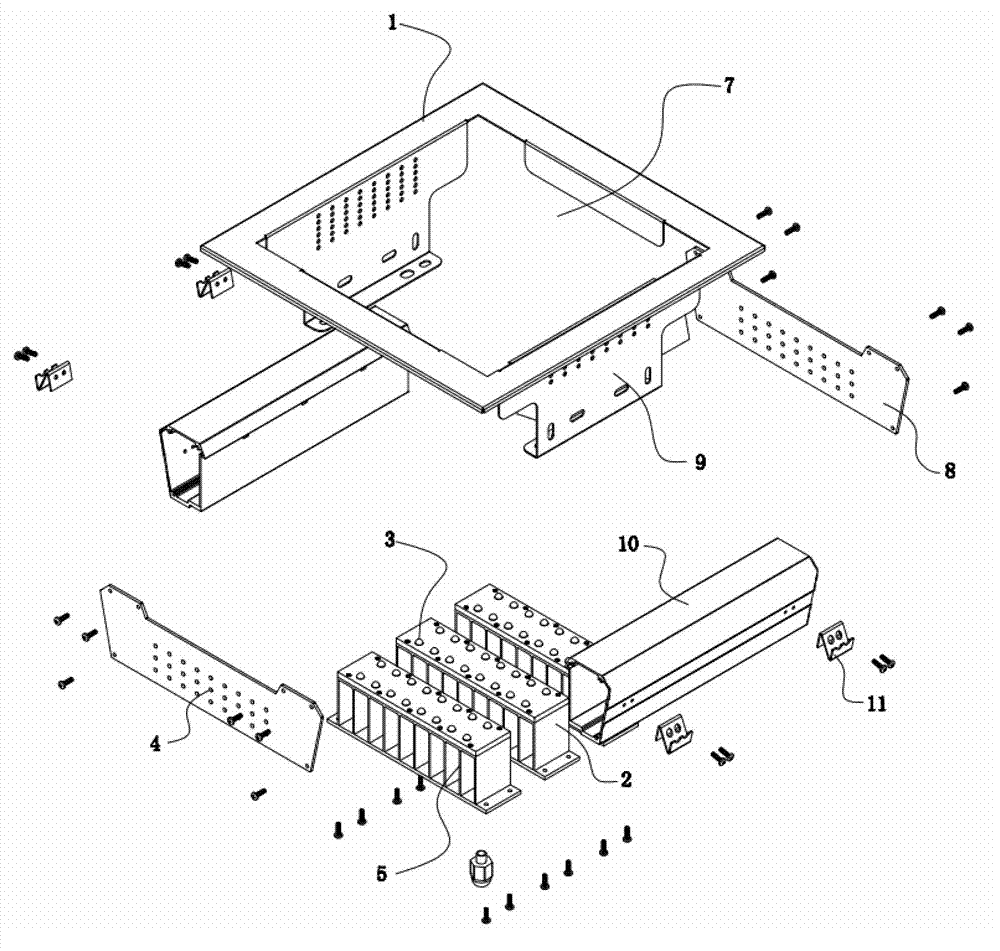

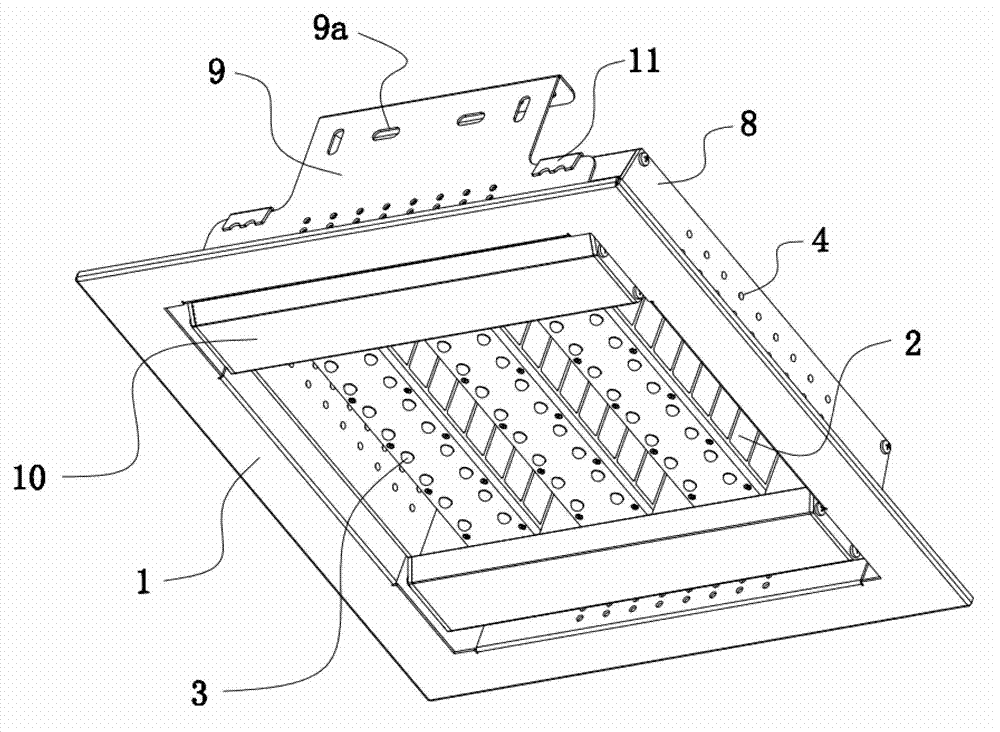

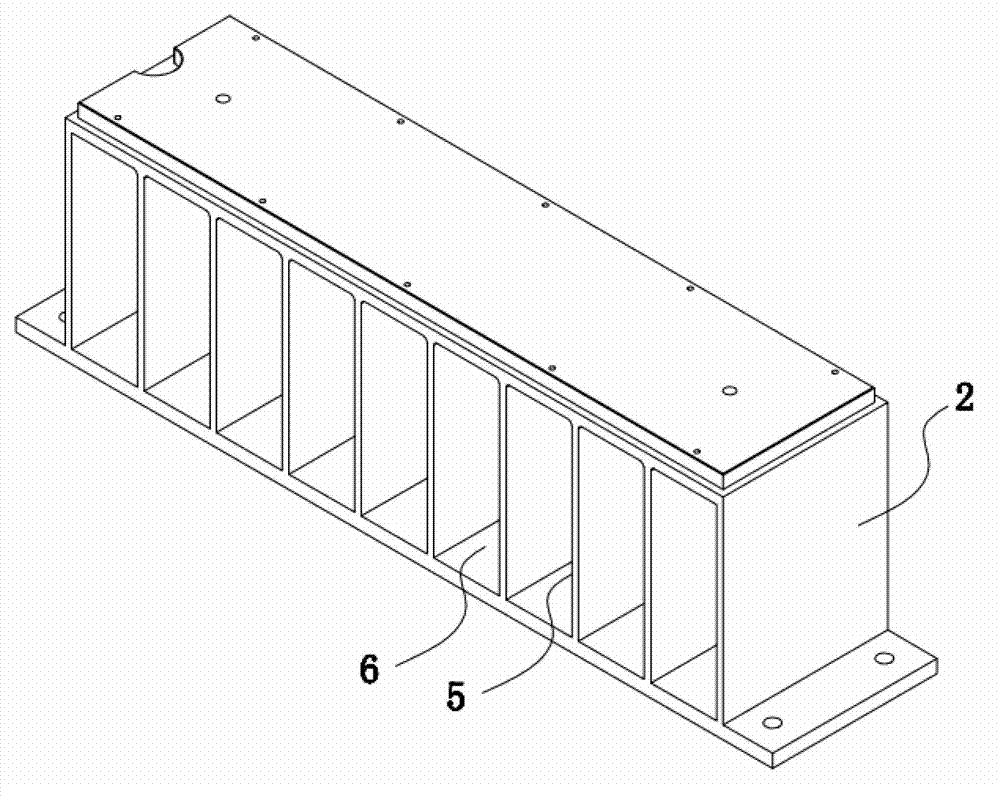

[0041] Such as Figure 1 to Figure 10As shown, the micro-power cooling, heat, convection, heat dissipation and dust-resistant LED lamps of this embodiment include a housing 1 and a radiator arranged in the middle of the housing 1. The housing 1 can be connected to an external substrate (such as a roof, a wall, etc.), Several LED light source chips 3 are arranged on the heat sink, the heat sink is a sheet radiator 2, the side of the housing 1 is provided with ventilation holes 4, and the sheet radiator 2 is provided with several The heat exchange channels 6 separated by the vertical fins 5 are arranged towards the ventilation holes 4. The interior of the housing 1 communicates with the outside world through the ventilation holes 4 to dissipate heat. The opening direction of the heat exchange channel 6 is consistent, the air convection is formed inside the housing 1 and between the vertical fins 5 of the radiator, the air inside and outside the housing 1 circulates, and the heat...

Embodiment 2

[0045] Such as Figure 1 to Figure 10 As shown, in this embodiment, in order to further simplify the connection structure and improve the efficiency of disassembly and assembly, two profiles 10 are arranged in the rectangular frame, and the profile 10 and the hanging plate 9 are arranged on the same side of the rectangular frame, as Figure 7 As shown, the profile 10 is in the shape of a cuboid as a whole and extends along the sides of the rectangular frame. The two ends of the profile 10 are respectively connected to the two side plates 8. The outside of the profile 10 is provided with a hook 11. The hook 11 is snap-connected with the upper end surface of the hanging plate 9. The profile 10 in this embodiment is used as a transition piece between the rectangular frame and the radiator. The profile 10 and the hook 11 arranged on the side of the profile 10 will The radiator is card-type connected to the rectangular frame, which is easy to disassemble and assemble. In the actua...

Embodiment 3

[0052] Such as Figure 1 to Figure 10 As shown, in this embodiment, three fin radiators 2 are arranged along the extension direction of the profile 10, the bottom plate of the fin radiator 2 is connected to the top surface of the profile 10, and the two adjacent fin radiators 2 There is a gap between them. Before connecting the LED lamps to the base, according to the needs, arrange several groups of fin radiators 2 along the extension direction of the profile 10. This part of the operation can be carried out in the operating space such as the workbench, which is convenient and quick. The operation is limited by the outside world. After the heat sink is connected to the profile 10, the profile 10 can be snap-connected and hung on the rectangular frame through the hook 11. The assembly is convenient and fast.

[0053] In other embodiments, the number of fin radiators 2 arranged along the extending direction of the profile 10 can also be two, four or more, and will not be repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com