Low-NOX air-coal-powder optimized burner group

A technology for optimizing combustion and air powder, applied in the direction of using various fuel combustion, combustion methods, combustion types, etc., to achieve the effects of reducing NOX emissions, avoiding furnace slagging, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

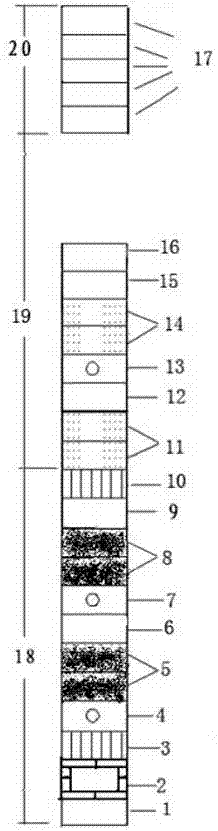

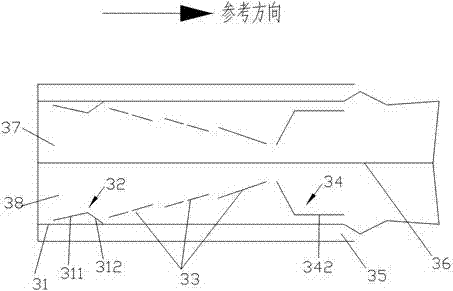

[0024] Such as figure 1 shown, a low NO X The air powder optimized burner group, the burners are arranged at the four corners of the furnace, and are arranged in layers in the height direction. The order from bottom to top is: secondary air I nozzle 1, micro-oil ignition primary air nozzle I2, offset secondary air nozzle 3. Oil air chamber 4, concentrated primary air nozzle 5, secondary air I nozzle 6, oil air chamber 7, concentrated primary air nozzle 8, secondary air I nozzle 9, offset secondary air nozzle 10, light primary air nozzle 11. Secondary air I spout 12, oil air chamber 13, light primary air spout 14, secondary air I spout 15 and fire upper wind spout (16 and 17). The primary wind of the same layer (here refers to the air powder flow of the micro-oil ignition primary air nozzle, thick primary air nozzle, and light primary air nozzle of the same layer) anti-tangential circle, secondary air I (in order to distinguish it from the offset secondary wind , named as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com