Material level detection method based on linear array temperature sensor

A temperature sensor and detection method technology, applied in the direction of liquid level indicator for physical variable measurement, etc., can solve the problems of inapplicability, inability to measure material level data, poor low temperature resistance of sensors, etc., and achieve low manufacturing cost and theoretical reliability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

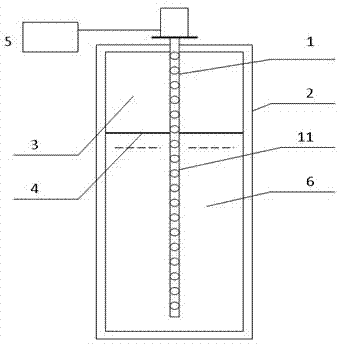

Embodiment 1

[0034]Embodiment 1: The data collection and processing terminal 5 adopts Samkoon Company with RS485 interface, Modbus communication protocol, and 3.5-inch touch-type man-machine interface. The human-machine interface can run programs written in C language to realize data communication and data processing functions; the temperature sensor line array 1 consists of a group (typically 10 per meter) of digital temperature sensors with single-bus data communication capabilities Composed of DS18b20 and a microprocessor (MCU) capable of communicating with single bus and capable of communicating with data acquisition and processing terminal 5 through Modbus protocol (such as Nuvoton's W79E824), its peripheral circuits (such as power supply circuit, etc.) and RS485 communication interface , The digital temperature sensor DS18b20 is evenly spaced, armored on the rod of a poor thermal conductor of appropriate length, and ensures good thermal contact with the measured medium.

[0035] Its ...

Embodiment 2

[0036] Embodiment 2: The temperature sensor line array 1 is composed of multiple (such as 24) digital temperature measuring elements DS18b20, which are evenly distributed in the vertical direction for armoring. The armored rods have good heat conduction in the horizontal direction where the temperature measuring elements are installed. The interval direction of the adjacent temperature measuring element is insulated, the armor is sealed inside and outside, and a microprocessor (MCU) is used to collect temperature signal data. Through the RS485 of the microprocessor (MCU), the upper intelligent controller (data acquisition and processing) terminal) to output the temperature digital signal sequence collected at each point, the circuit principle is as follows Figure 4 shown.

[0037] The upper intelligent controller (data acquisition and processing terminal) takes the 51-core MCU as the core, connects the armored level sensor through the RS485 interface, and obtains the temperat...

Embodiment 3

[0039] Example 3: When the temperature of the measured medium is lower (lower than -55°C) and the temperature of the measured medium is higher (greater than 125°C), the temperature measuring element uses platinum resistance. Multiple (such as 24) platinum resistors are evenly distributed in the vertical direction for armoring. The armored rod has good heat conduction in the horizontal direction where the temperature measuring element is installed, and the space between adjacent temperature measuring elements is insulated. seal. For every 8 temperature measuring platinum resistance thermometers, use one MSC1210 (51 core) microprocessor (MCU) with 8-channel 24bit Σ-ΔADC, and use a four-wire bridge to collect temperature signals. A total of 3 MSC1210 microprocessors are used ( MCU) (chip1, chip2 and chip3), bridge each other through the RS232 interface, each microprocessor (MCU) transmits data to the upper MCU, through the RS485 interface of the end microprocessor (MCU), the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com