Preparation method and application of ferroferric oxide-graphite carbon nitride composite magnetic photocatalyst

A technology of ferroferric oxide and carbon nitride-like, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., which can solve the problem of not being able to achieve solid-liquid separation well, limiting the range of visible light absorption, Photocatalyst extraction and other issues, to achieve the effect of improving photocatalyst efficiency, broad application prospects, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

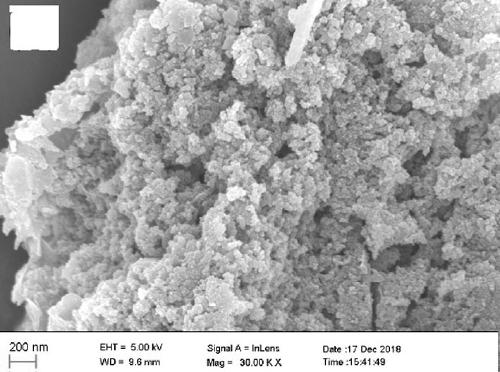

Image

Examples

Embodiment 1

[0028] A preparation method of ferric oxide-graphite carbon nitride composite magnetic photocatalyst, comprising the steps of:

[0029] a) Put dicyandiamide, the precursor of graphite-based carbon nitride, in a muffle furnace, and heat it in an air atmosphere at 500 °C for 2.0 h, with a heating rate of 2.5 °C min -1 , to be cooled to room temperature, ground into powder, that is graphite carbon nitride;

[0030] b) Mix choline chloride and urea at a mass ratio of 1:1, and dissolve them in 5ml of deionized water. After mixing, place the solution at 35°C for 20 minutes to prepare a deep eutectic solvent;

[0031] c) the graphitic carbon nitride and FeSO prepared in step a) 4 ·7H 2 O and NaOH were mixed according to the mass ratio of 1:0.05:0.018, and added to the deep eutectic solvent prepared in step b), reacted at 30°C for 20min, and the stirring speed was 500r·min -1 ;

[0032] d) Add 0.0126g of NaOH to the mixed solution prepared in step c), react at 70°C for 20min, tran...

Embodiment 2

[0036] A preparation method of ferric oxide-graphite carbon nitride composite magnetic photocatalyst, comprising the steps of:

[0037] a) Put graphite carbon nitride precursor melamine in a muffle furnace, heat at 520 °C for 2.5 h in an air atmosphere, and the heating rate is 3.0 °C min -1 , to be cooled to room temperature, ground into powder, that is graphite carbon nitride;

[0038] b) Mix choline chloride and urea at a mass ratio of 1.2:1, and dissolve them in 10ml of deionized water. After mixing, place the solution at 50°C for 30 minutes to prepare a deep eutectic solvent;

[0039] c) the graphitic carbon nitride and FeSO prepared in step a) 4 ·7H 2 O and KOH were mixed according to the mass ratio of 1:0.1:0.036, and added to the deep eutectic solvent prepared in step b), reacted at 50°C for 30min, and the stirring rate was 600r·min -1 ;

[0040] d) Add 0.0252g of KOH to the mixed solution prepared in step c), react at 80°C for 30min, transfer to the reaction kettle...

Embodiment 3

[0044] A preparation method of ferric oxide-graphite carbon nitride composite magnetic photocatalyst, comprising the steps of:

[0045] a) Put graphite carbon nitride precursor thiourea in a muffle furnace, heat at 550 °C for 3.0 h in an air atmosphere, and the heating rate is 3.5 °C min -1 , to be cooled to room temperature, ground into powder, that is graphite carbon nitride;

[0046]b) Mix choline chloride and urea according to the mass ratio of 1.5:1, and dissolve them in 15ml of deionized water. After mixing, place the solution at 65° C. for 40 minutes to prepare a deep eutectic solvent;

[0047] c) the graphitic carbon nitride, FeCl prepared in step a) 2 4H 2 O and KOH were mixed according to the mass ratio of 1:0.2:0.072, and added to the deep eutectic solvent prepared in step b), reacted at 40°C for 40min, and the stirring rate was 700r·min -1 ;

[0048] d) Add 0.0504g of KOH to the mixed solution prepared in step c), react at 90°C for 40min, transfer to the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com