Preparation method of CA-Al-KABs xerogel adsorbent and application of CA-Al-KABs xerogel adsorbent in wastewater treatment

A technique of ca-al-kabs and xerogel, which is applied in the field of adsorbent synthesis, can solve the problems of limited application of antibiotics, difficulty in solid-liquid separation, limited adsorption capacity of antibiotics, etc., to achieve reliable theoretical and practical support, broad application prospects, The effect of solving the difficulty of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

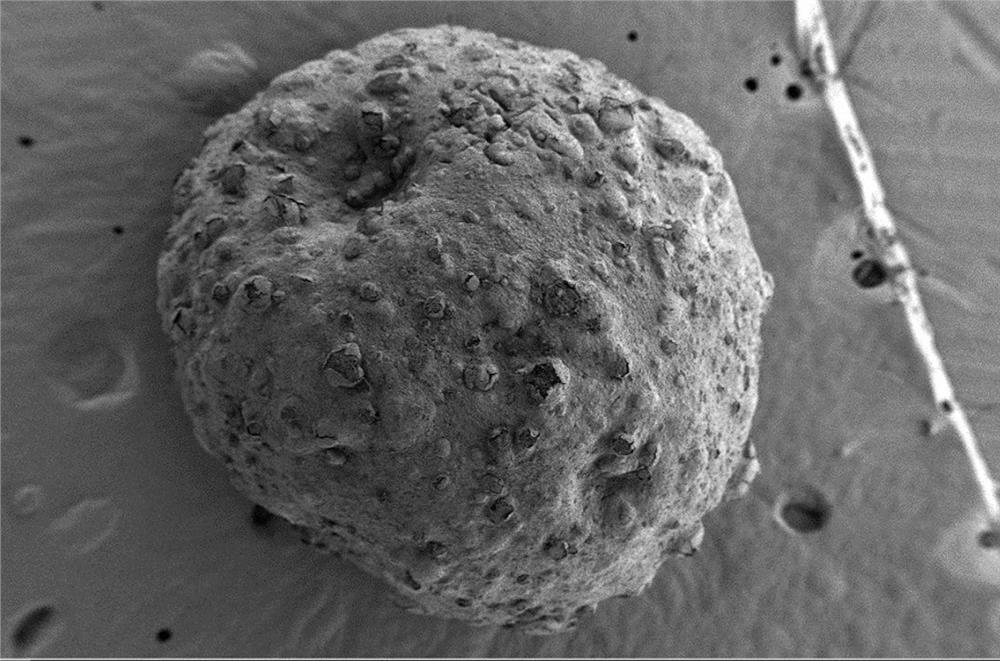

Image

Examples

Embodiment 1

[0029] A preparation method of CA-Al-KABs xerogel adsorbent, comprises the steps:

[0030] a) Disperse 20 g of kaolin in 100 mL of deionized water and shake for 8 h, let it stand for 15 min, and discard the precipitated part to obtain a kaolin suspension;

[0031] b) Mix the suspension with 50 mL, 1.0 mol / L NaCl solution and stir for 12 h, remove the supernatant after settling, wash the resulting solid with ultrapure water for 3 times, then dry at 60 °C for 12 h, grind to 100-200 meshes to obtain Na-Kaolin;

[0032] c) Under vigorous stirring in a water bath at 60 °C, add 0.4 mol / L AlCl to 50 mL 3 ·6H 2 Slowly drop 50mL, 0.96 mol / L NaOH solution into the O solution, and stir for 20 min to obtain the Al pillared solution;

[0033] d) Disperse 2.5 g of Na-Kaolin in 100 mL of deionized water, then drop 100 mL of 0.2 mol / L Al pillar solution into it, stir for 22 h, let stand for 12 h, and wash the resulting precipitate with ultrapure water 3 times, then dried at 60 °C for 12 h...

Embodiment 2

[0038] A preparation method of CA-Al-KABs xerogel adsorbent, comprises the steps:

[0039] a) Disperse 20 g of kaolin in 100 mL of deionized water and shake for 8 h, let it stand for 15 min, and discard the precipitated part to obtain a kaolin suspension;

[0040] b) Mix the suspension with 50 mL, 1.0 mol / L NaCl solution and stir for 12 h, remove the supernatant after settling, wash the resulting solid with ultrapure water for 3 times, then dry at 60 °C for 12 h, grind to 100-200 meshes to obtain Na-Kaolin;

[0041] c) Under vigorous stirring in a water bath at 60 °C, add 0.4 mol / L AlCl to 50 mL 3 ·6H 2 Slowly drop 50mL, 0.96 mol / L NaOH solution into the O solution, and stir for 20 min to obtain the Al pillared solution;

[0042] d) Disperse 2.5 g of Na-Kaolin in 100 mL of deionized water, then drop 100 mL of 0.2 mol / L Al pillar solution into it, stir for 22 h, and let it stand for 12 h. Wash 3 times, then dry at 60°C for 12 hours, and grind to 100-200 mesh to obtain Al-Ka...

Embodiment 3

[0047] A preparation method of CA-Al-KABs xerogel adsorbent, comprises the steps:

[0048] a) Disperse 20 g of kaolin in 100 mL of deionized water and shake for 8 h, let it stand for 15 min, and discard the precipitated part to obtain a kaolin suspension;

[0049] b) Mix the suspension with 50 mL, 1.0 mol / L NaCl solution and stir for 12 h, remove the supernatant after settling, wash the resulting solid with ultrapure water for 3 times, then dry at 60 °C for 12 h, grind to 100-200 meshes to obtain Na-Kaolin;

[0050] c) Under vigorous stirring in a water bath at 60 °C, add 0.4 mol / L AlCl to 50 mL 3 ·6H 2 Slowly drop 50mL, 0.96 mol / L NaOH solution into the O solution, and stir for 20 min to obtain the Al pillared solution;

[0051] d) Disperse 2.5 g of Na-Kaolin in 100 mL of deionized water, then drop 100 mL of 0.2 mol / L Al pillar solution into it, stir for 22 h, and let it stand for 12 h. Wash 3 times, then dry at 60°C for 12 hours, and grind to 100-200 mesh to obtain Al-Ka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com