Method for measuring homogeneous degree of fodder

A uniformity and feed technology, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as the inability to truly reflect the mixing uniformity of feed, and achieve the effects of improving detection accuracy, real response, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

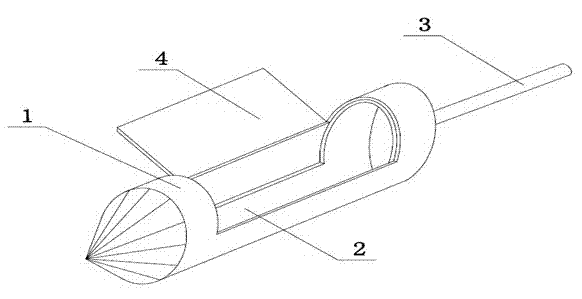

Image

Examples

Embodiment 1

[0026] A method of measuring feed uniformity, comprising the steps of:

[0027] (1) Preparation of methyl violet tracer

[0028] (1) Dissolve 10 g of methyl violet in 200 mL of ethanol with a concentration of 95% by volume to prepare a methyl violet solution;

[0029] (2) Mix the methyl violet solution prepared in step (1) with 2000 g of calcium hydrogen phosphate, and stir evenly. The particle size of the calcium hydrogen phosphate is 100 mesh;

[0030] (3) Open and dry the mixture of the methyl violet solution and the tracer carrier in step (2) to evaporate the ethanol solvent to obtain the methyl violet tracer.

[0031] (2) Preparation of feed samples

[0032] After adding 1t of feed into the mixer, add 2kg of methyl violet tracer into the mixer and mix evenly.

[0033] (3) Determination of uniformity

[0034] Use a sampler to collect samples from different positions in the mixer, measure the content of methyl violet in the samples by colorimetry, and use the difference...

Embodiment 2-4

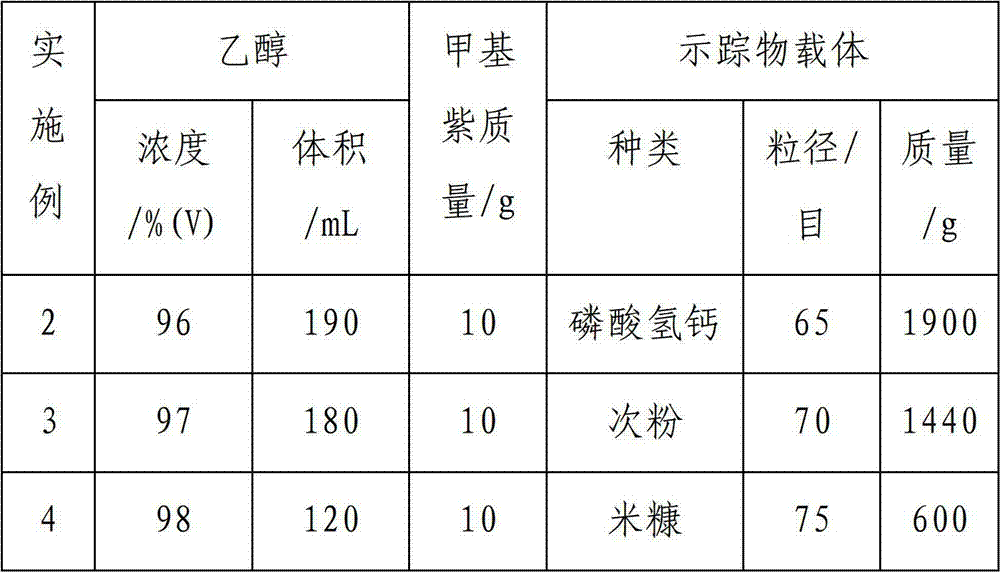

[0036] (1), the method for preparing methyl violet tracer

[0037] The methyl violet tracer was prepared according to the steps described in Example 1. Compared with Example 1, some parameters involved in the method are different, as shown in Table 1. Unless otherwise specified, they are all the same as in Example 1.

[0038] Table 1

[0039]

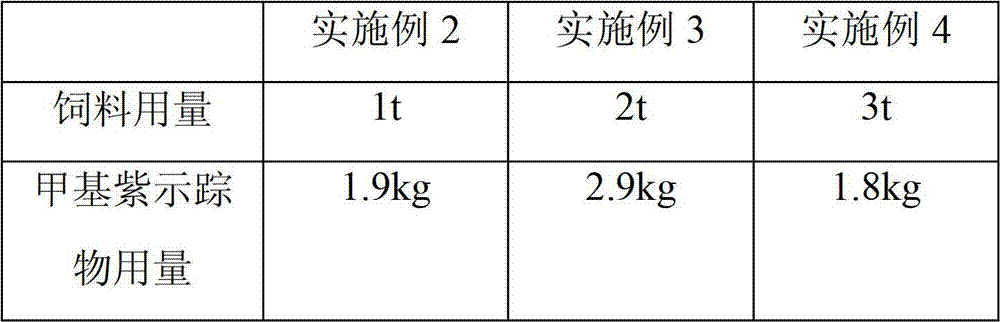

[0040] (2) Preparation of feed samples

[0041] After adding the feed into the mixer, add the methyl violet tracer into the mixer and mix well.

[0042] The specific addition amount is shown in the table:

[0043] Table 2

[0044]

[0045] (3) Determination of uniformity

[0046] Use a sampler to collect samples from different positions in the mixer, measure the content of methyl violet in the samples by colorimetry, and use the difference in the content of methyl violet in the samples at different positions in the feed to reflect the mixing uniformity of the feed.

[0047] With the methyl violet tracer prepared by embodiment...

Embodiment 5

[0059] A method of measuring feed uniformity, comprising the steps of:

[0060] (1), the method for preparing methyl violet tracer, comprises the following steps:

[0061] (1) Dissolve 10 g of methyl violet in 150 mL of ethanol with a concentration of 95% by volume, and filter to obtain a methyl violet solution;

[0062] (2) Mix the methyl violet solution prepared in step (1) with 1500 g of calcium hydrogen phosphate, stir evenly, and the particle size of the calcium hydrogen phosphate is 65 mesh;

[0063] (3) Open and dry the mixture of the methyl violet solution and the tracer carrier in step (2) to evaporate the ethanol solvent to obtain the methyl violet tracer.

[0064] (2) Preparation of feed samples

[0065] After adding 1t of feed into the mixer, add 1.5kg of methyl violet tracer into the mixer and mix evenly.

[0066] (3) Determination of uniformity

[0067] Use a sampler to collect samples from different positions in the mixer, measure the content of methyl viole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com