Rapid determination method for content of calcium in limestone flour

A rapid determination of calcium content technology, applied in the preparation of test samples, material analysis by observing the impact on chemical indicators, analysis by making materials undergo chemical reactions, etc., can solve the problem of long time-consuming determination and achieve The effect of accurate determination of calcium content and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The determination of calcium content in stone powder is carried out as follows:

[0016] (1) Accurately weigh the stone powder sample (m, 0.2~0.5g), add 10 mL of 1:1 hydrochloric acid aqueous solution (V / V), stir well to completely dissolve the stone powder, and let it stand at room temperature for 5 minutes. Transfer this solution completely into a 100mL volumetric flask, dilute it to the 100mL mark with distilled water, and shake it up to become a sample decomposition solution.

[0017] (2) Accurately pipette 10mL of the sample decomposition solution into a 200mL beaker, add 100mL of distilled water, 2 drops of methyl red indicator (1.0gL, 0.1g of methyl red dissolved in 100mL of 95% ethanol), add 1:1 Ammonia solution (V / V) until the solution turns orange, then add 2 more drops to make the solution pink, boil carefully, and slowly heat 10mL of ammonium oxalate solution (42.0gL, 4.2g ammonium oxalate dissolved in 100mL water), while adding While stirring, boil for 5~10min,...

Embodiment 2

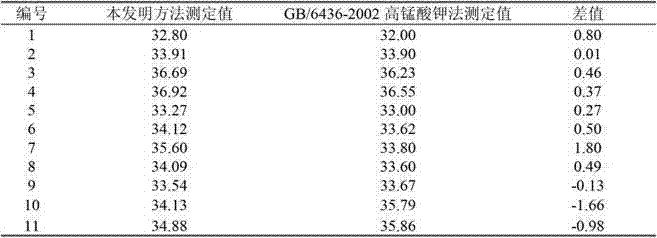

[0023] 1. Collect 11 stone powder samples, and measure the calcium content in them by the method described in the examples and the potassium permanganate method in GB / 6436-2002, and compare the differences between the two.

[0024] 2. Test results

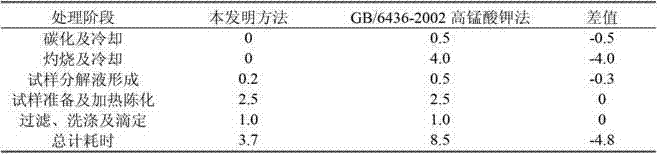

[0025] The measurement results show that the calcium content in the stone powder determined by the method of the present invention is less time-consuming than the GB / 6436-2002 potassium permanganate method (Table 1), and the method of the present invention is comparable to the GB / 6436-2002 potassium permanganate method. Compared with the method, the difference of the measurement results is small, and the variation range of 11 samples is 0.03~5.33% (Table 2). The method of the invention reduces the time-consuming measurement significantly, and the result is accurate.

[0026] Table 1 Comparison of the time consumption of the two methods to determine the calcium content in stone powder (h)

[0027]

[0028] Table 2 Comparison of two methods...

Embodiment 3

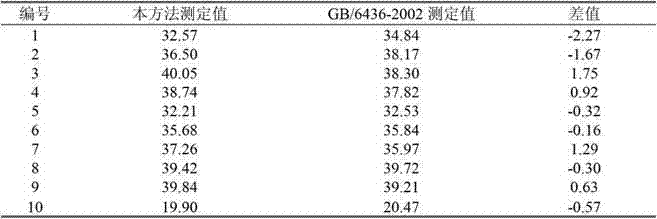

[0031] 1. Collect 10 pieces of stone powder samples, and measure the calcium content in them by the method described in the examples and the potassium permanganate method in GB / 6436-2002, and compare the differences between the two.

[0032] 2. Test results

[0033] The measurement results show that the calcium content in the stone powder measured by the method of the present invention has a small difference compared with the GB / 6436-2002 method, and the variation range of 10 samples is 0.45~6.52% (Table 3).

[0034] Table 3 Comparison of two methods for determining calcium content in stone powder (%)

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com