Method and system for rapidly three-dimensionally microimaging large sample

A micro-imaging and large-sample technology, which is applied in microscopes, instruments, optics, etc., can solve problems that affect imaging quality, limit development, affect imaging speed and imaging effect, and achieve the effect of reducing exposure and avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

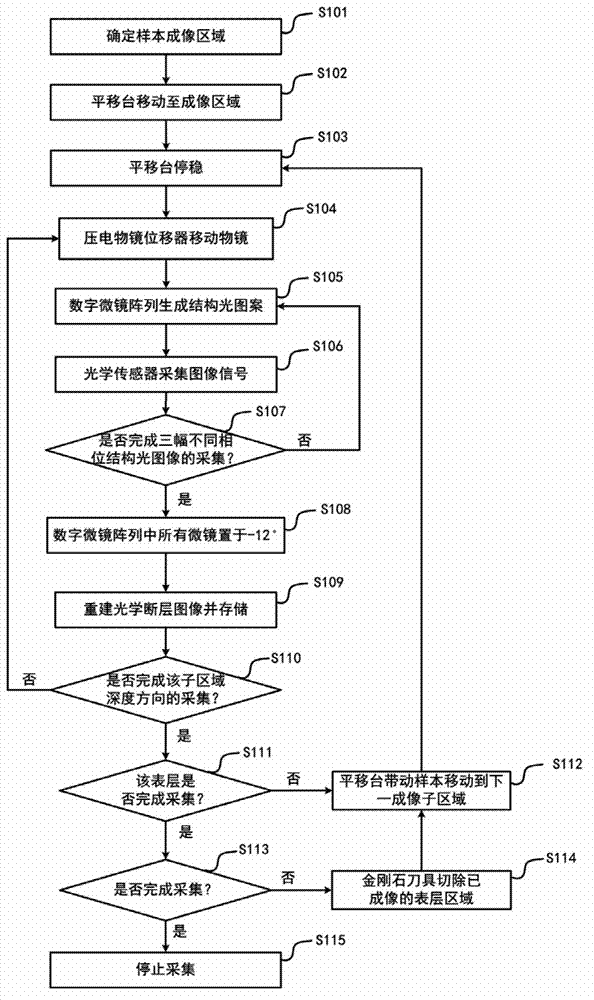

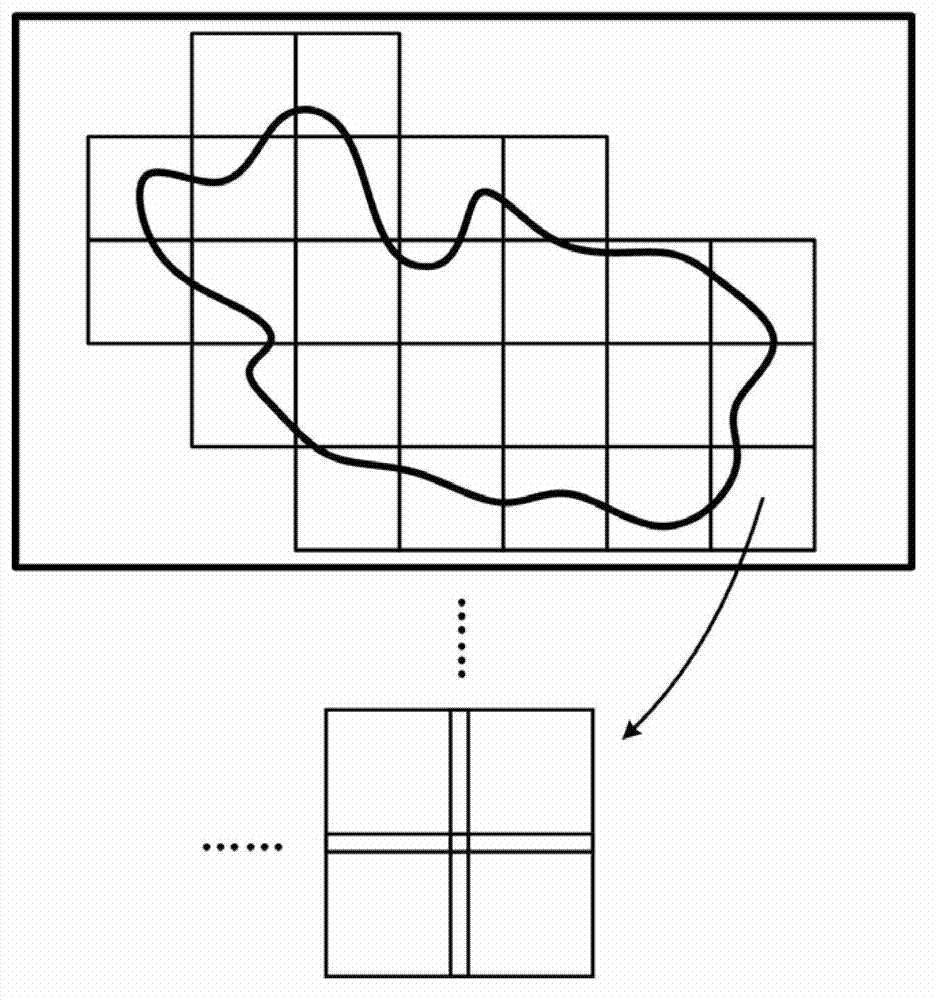

Method used

Image

Examples

Embodiment

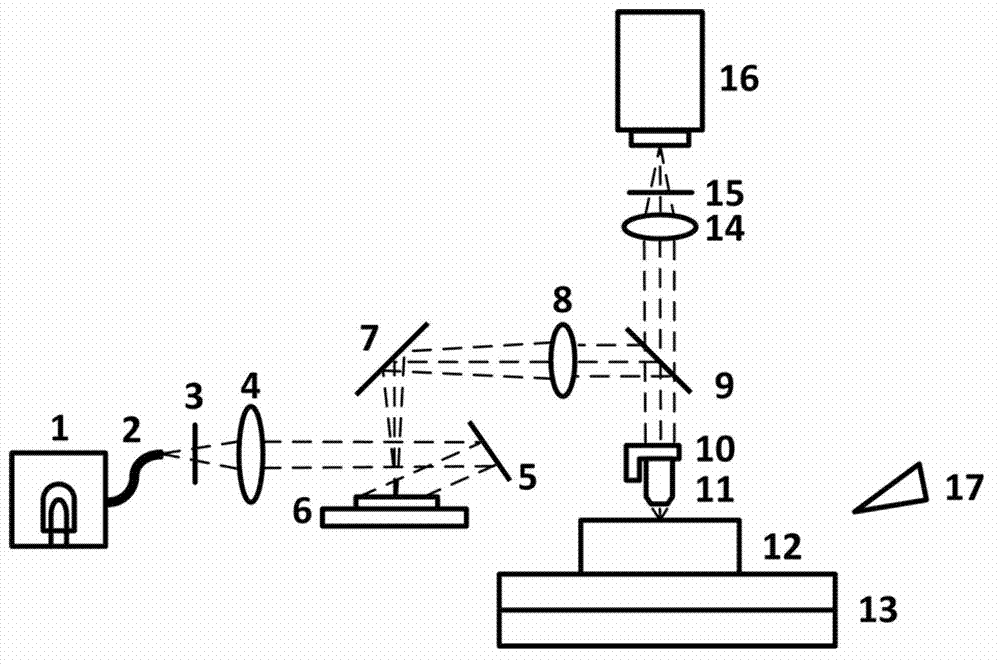

[0040] The light source is the X-cite 120 metal halide light source produced by Lumen Dynamics, which has its own output fiber. The specification of the digital micromirror array is 0.7 XGA, and the micromirror has two working states of +12° and -12°. The precision three-dimensional electric translation stage adopts the products of Aerotech Company of the United States. The precision three-dimensional electric translation stage is placed on the marble platform, and the positioning accuracy is sub-micron level to meet the needs of precision cutting and imaging. The diamond tool adopts the straight-edge diamond tool commonly used in electron microscope science, the blade angle is 35°, and the width is 3 mm. The tool and the tool holder are fixed on the steel tool holder.

[0041] The imaging objective lens is a 40x achromatic objective lens from Olympus, Japan. The piezoelectric displacement device uses the product of German PI company, and its positioning accuracy can reach 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com