Automobile engine strong-force high-tension ignition wire

A high-voltage ignition and automobile technology, applied to circuits, electrical components, insulated cables, etc., can solve problems such as excessive resistance, increased fuel consumption and harmful emissions of automobiles, and increased conductive wire cores, so as to increase the high-voltage ignition voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

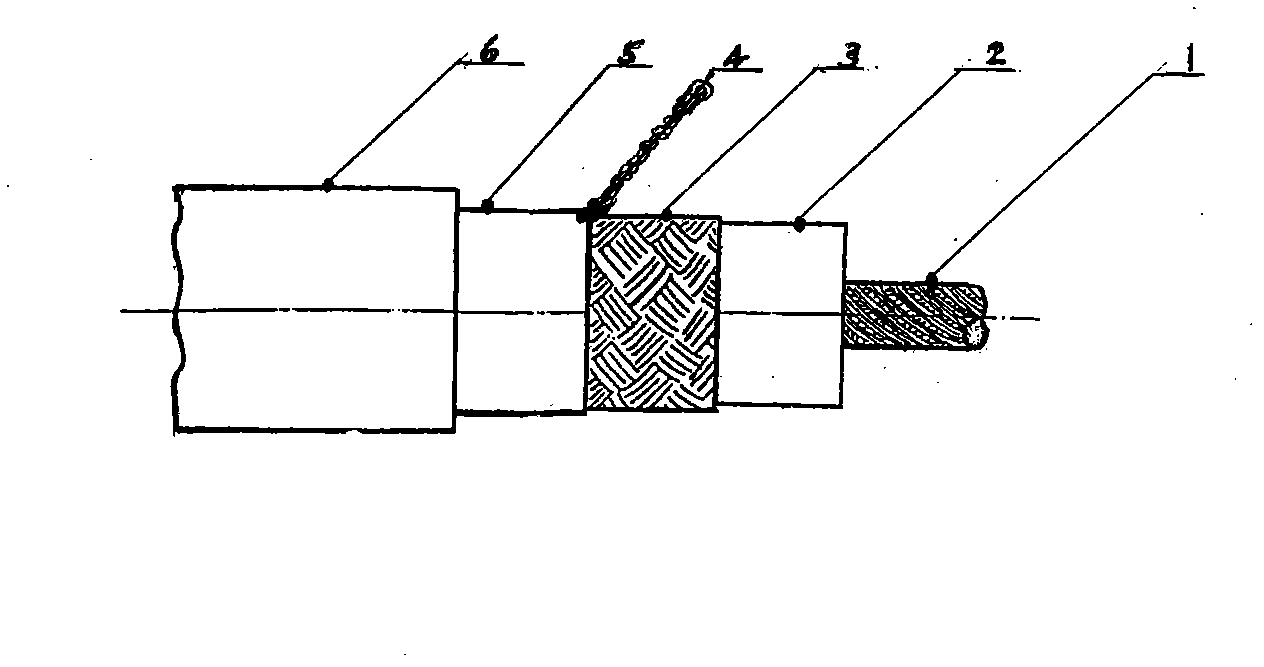

Image

Examples

Embodiment Construction

[0013] 4.1 The national standard GB / T 14820.3--93 stipulates that the DC resistance of the reactance core at 20°C should be greater than It has been shown from long-term practice that this resistance value should be appropriately reduced to increase the spark energy of ignition. Under the premise of sufficient shielding measures (see 4.3 below), generally 0.5-- It is appropriate. From the principle of electrical engineering, it can be concluded that: In contrast, the spark energy can be increased by 3.2--6.4 times.

[0014] 4.2 The technical performance of the high-voltage insulating rubber of the wire is very important to the quality of the wire, especially the electric strength and heat aging resistance. Practice has shown that the high-voltage insulating rubber obtained by using the rubber compound blended with EPDM rubber and low-density polyethylene plastic, and carefully designed and tested, has a dense rubber texture and is resistant to AC. The power frequency br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com