Metal layer etching method and metal layer mask structure

A metal layer and etching technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to overcome thickness limitations, improve flatness, and avoid faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

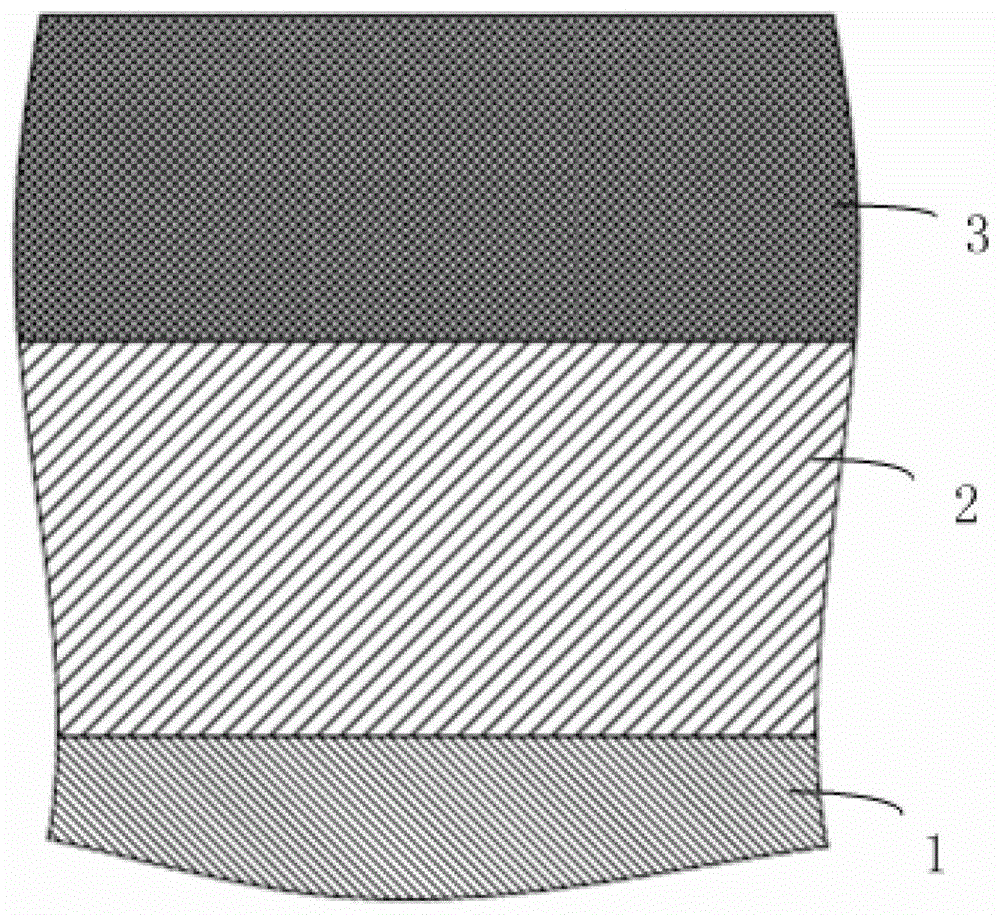

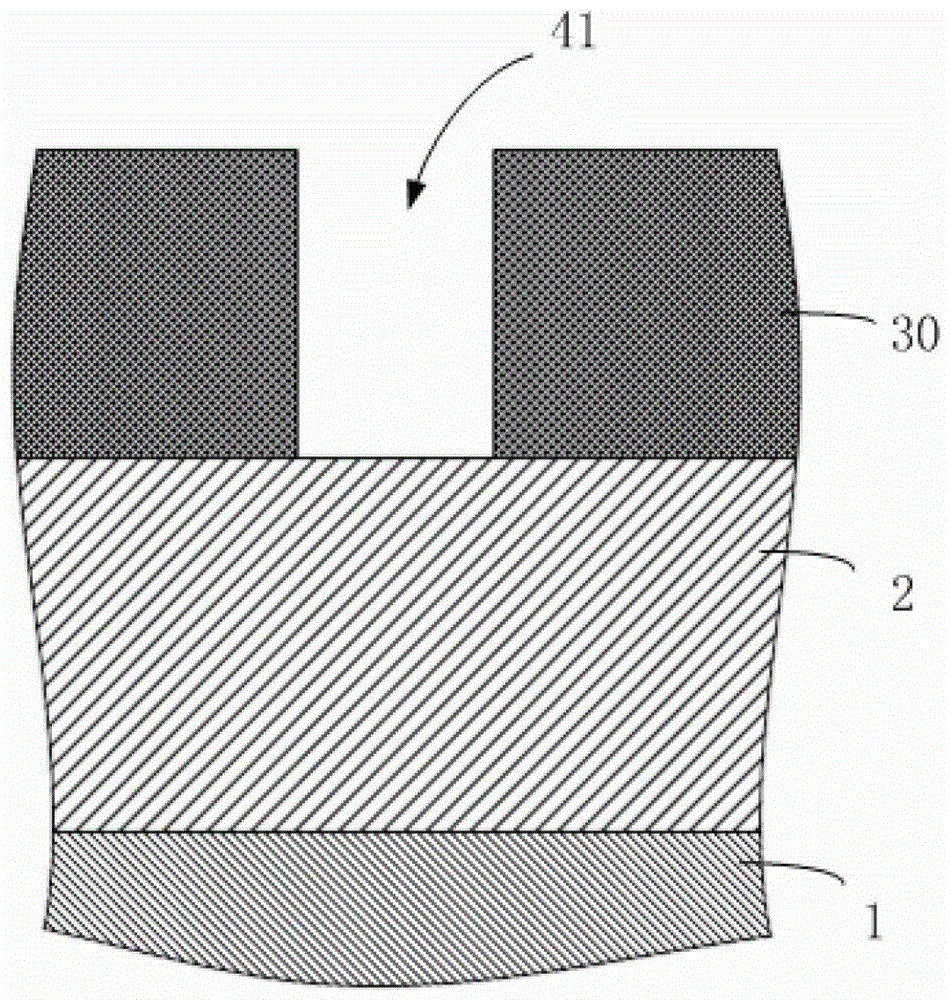

[0035] The invention provides an etching method of a metal layer, so as to improve the flatness of the sidewall surface of the thick metal layer after etching, and improve the consistency of key dimensions and inductance performance after detection after development and detection after etching. Utilizing the etching method of the present invention can also overcome the limitation of the thickness of the photoresist layer.

[0036] Please refer to Figure 7 , Figure 7 It is a schematic flow chart of the etching method of the embodiment of the present invention, please refer to it in each step figure 1 and Figure 8 to Figure 12 .

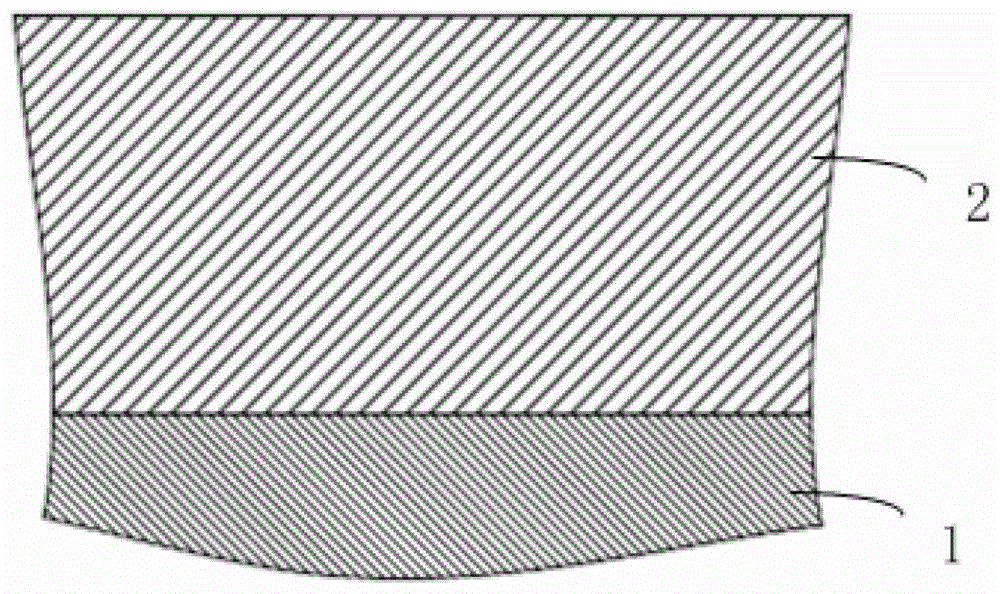

[0037] Step S1, please refer to figure 1 In the etching method of the thick metal layer 2 provided in this embodiment, firstly, a semiconductor structure is provided, and the semiconductor structure includes the metal layer 2 . The semiconductor structure may be a wafer, and the wafer may be a typical semiconductor wafer made of silicon, or a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com