High-purity nickel target for magnetron sputtering

A magnetron sputtering, nickel target technology, used in sputtering plating, metal material coating process, ion implantation plating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

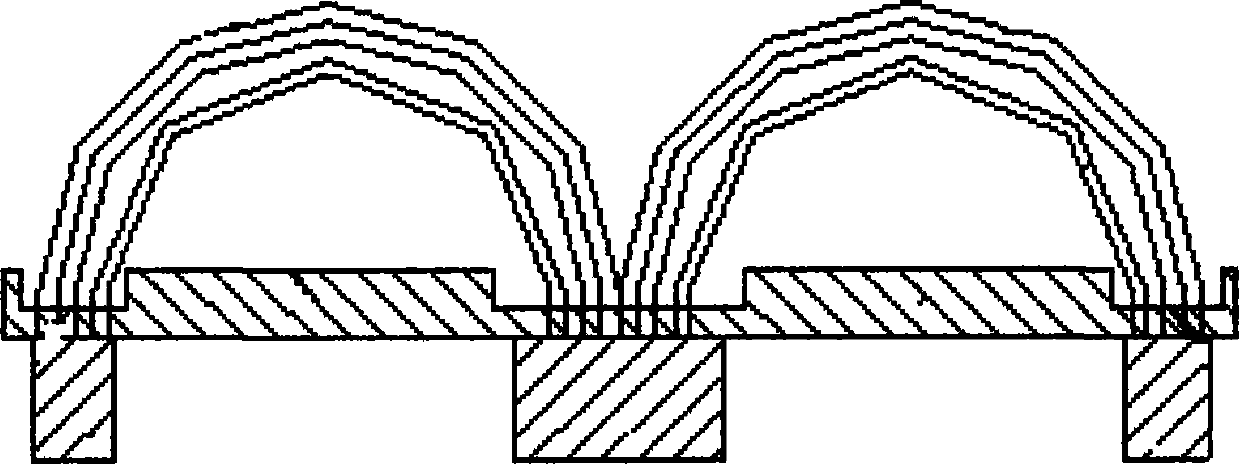

[0042] Increase the thickness of the target to 13mm. On the sputtering surface, use a milling machine to mill out a trapezoidal groove with a depth of 7mm at the top and a narrow bottom at the straight line, and mill a groove with a depth of 4mm at the curve. The curve is trapezoidal. The height of the road section transitions smoothly. The target is plated on the surface of the polyester film, and the utilization rate of the target (etching mass / total mass of the target x 100%) is 60% higher than that of the pure nickel target of equal thickness used in the past; the pure nickel target with grooves is coated The lateral resistance is 8.3±0.3Ω when the confidence level is 95%, and the lateral resistance of the pure nickel target coating film without grooves (nickel target 10mm thick) is 9.3±1.3Ω when the confidence level is the same; % is 15% at the beginning, 50% in the middle and 85% at the end of coating, and the test resistances are 8.3±0.3Ω, 8.4±0.3Ω and 8.5±0.4Ω respecti...

Embodiment 2

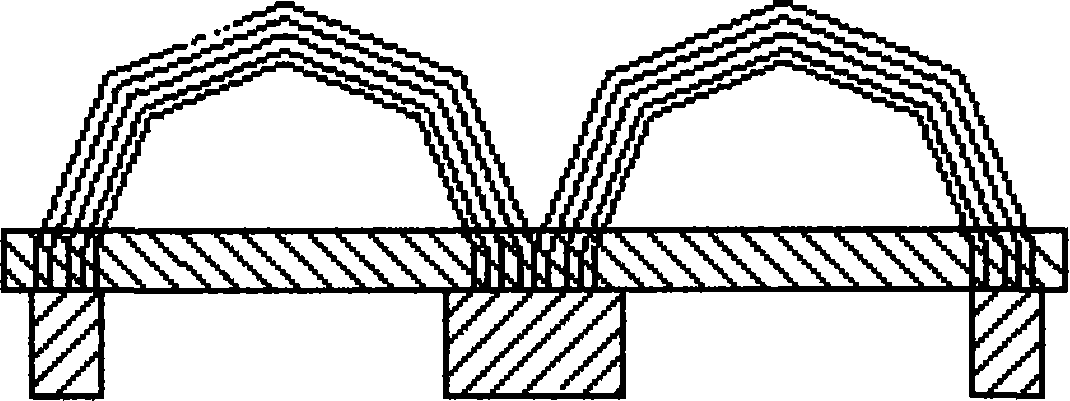

[0044] Increase the thickness of the target to 12mm. On the back of the sputtering surface, use a milling machine to mill a U-shaped groove with a depth of 5mm on the straight line, and mill a U-shaped groove with a depth of 3mm at the curve. The curve is arc-shaped, and the straight line and The height of the curve transitions smoothly, and the double-sided continuous plating of foam is adopted in the way of facing the target. The utilization rate of the target is increased by more than 50% compared with the pure nickel target of equal thickness used in the past. At the same time, due to the better cooling effect on the surface of the nickel target, the nickel target is not polluted by the volatile gas of the foam, while the pure nickel target of equal thickness used in the past has blackened deposits polluted by the volatile foam on the surface.

Embodiment 3

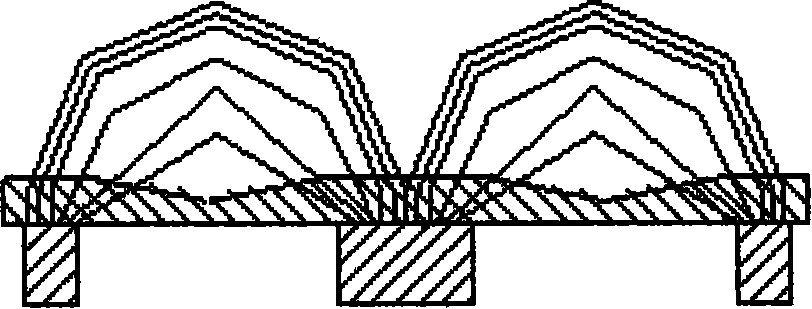

[0046] Prepare a pure nickel sputtering ring with a thickness of 8mm, which is rectangular in shape, and uniformly drill 16 screw holes with a diameter of 8mm on the non-sputtering surface, and pass the pure nickel sputtering ring and the flat nickel plate with a thickness of 5mm through the bolt with a gasket Assembled together, the polyester film is continuously plated on both sides by the target method, and the target utilization rate is increased by 50% compared with the equal-thickness pure nickel target used in the past.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com