Solar cell module support member and machining process thereof

A technology for solar cell components and processing technology, applied in electrical components, sustainable manufacturing/processing, support structure of photovoltaic modules, etc., can solve the problems of heavy glass weight, insufficient rigidity, failure, etc. The effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

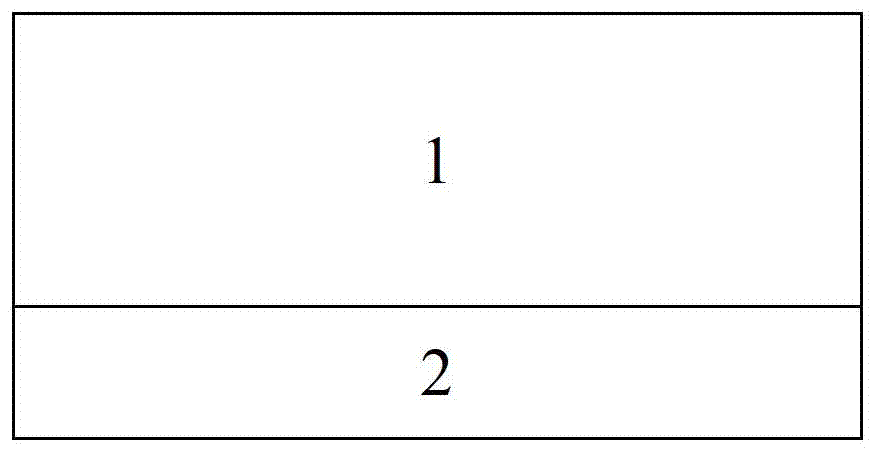

[0032] The thickness of the surface layer 1 of the support for solar cell modules is 0.1 mm, the thickness of the bottom layer 2 is 0.1 mm, the weight ratio of norbornene copolymer to PA is 1.1:1, or the weight ratio of norbornene copolymer to PP is 1.1:1, or the weight ratio of norbornene copolymer to PVDF is 1.1:1, and the weight ratio of norbornene copolymer to MAH-g-POE is 1.1:1.

Embodiment 2

[0034] The thickness of the surface layer 1 of the support for solar cell modules is 0.15 mm, the thickness of the bottom layer 2-1 is 0.1 mm, the thickness of the bottom layer 2-2 is 0.1 mm, and the weight ratio of norbornene copolymer to PA is 1.2:1, Or the weight ratio of norbornene copolymer and PP is 1.2:1, or the weight ratio of norbornene copolymer and PVDF is 1.2:1, or the weight ratio of norbornene copolymer and MAH-g-POE is 1.3: 1.

Embodiment 3

[0036] The thickness of the surface layer 1 of the support for solar cell modules is 0.2 mm, the thickness of the bottom layer 2-1 is 0.15 mm, the thickness of the bottom layer 2-2 is 0.15 mm, and the weight ratio of norbornene copolymer to PA is 1.3:1. Or the weight ratio of norbornene copolymer to PP is 1.3:1, or the weight ratio of norbornene copolymer to PVDF is 1.3:1, and the weight ratio of norbornene copolymer to MAH-g-POE is 1.3:1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com