Carbon fiber-containing ammonia storage mixture porous solid sample coupon and preparation method thereof

A porous solid and carbon fiber technology, which is applied in the direction of ammonia compounds, chemical instruments and methods, and other chemical processes, can solve the problems of no dosage ratio, no clear claim details, technical personnel can not implement, etc., to meet the use requirements , The effect of improving the ammonia storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

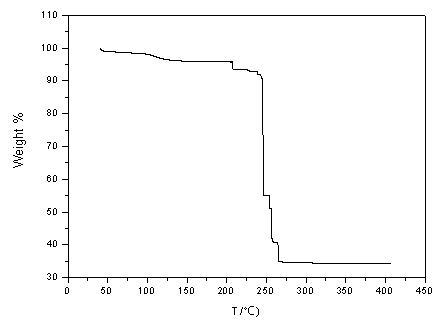

Image

Examples

Embodiment 1

[0018] (1) 68wt% of industrial anhydrous strontium chloride salt powder, 8wt% of carbon fiber, 4wt% of industrial ball clay, 12wt% of deionized water and 8wt% of industrial alcohol to form a mixture;

[0019] (2) The mixture is stirred evenly by a mixer for 1 hour to form a semi-dry mixed powder;

[0020] (3) Add the semi-dry mixed powder into an openable airtight container and shake it mechanically for 30 minutes to form a wet body sample;

[0021] (4) The sample block is at 80°C and the vacuum degree is 10 -1 Drying under the condition of kPa for 4h can obtain the active ammonia storage mixture porous solid sample block containing 10wt% carbon fiber.

[0022] Fill the 10g porous solid sample block with ammonia in a naturally ventilated environment. Put the openable airtight container in a water tank with enough cooling water in advance, connect the ammonia cylinder, and pass through the pressure reducing valve and the drying system. , fill the ammonia slowly within the pre...

Embodiment 2

[0024] (1) A mixture of 80wt% industrial anhydrous strontium chloride salt powder, 4wt% carbon fiber, 3wt% industrial spherical clay, 7wt% deionized water and 6wt% industrial alcohol;

[0025] (2) The mixture is stirred evenly by a mixer for 10 hours to form a semi-dry mixed powder;

[0026] (3) Add the semi-dry mixed powder into an openable airtight container and shake it mechanically for 60 minutes to form a wet body sample;

[0027] (4) The sample block was dried for 1 hour at 60°C under a vacuum of 1kPa to obtain a porous solid sample block of the active ammonia storage mixture containing 4.6wt% carbon fibers.

[0028] Fill the 10g porous solid sample block with ammonia in a naturally ventilated environment. Put the openable airtight container in a water tank with enough cooling water in advance, connect the ammonia cylinder, and pass through the pressure reducing valve and the drying system. , fill the ammonia slowly within the pressure range of 0.4Mpa, the ammonia filli...

Embodiment 3

[0030] (1) A mixture of 75wt% industrial anhydrous strontium chloride salt powder, 10wt% carbon fiber, 2wt% industrial ball clay, 3wt% deionized water and 10wt% industrial alcohol;

[0031] (2) The mixture is stirred evenly by a mixer for 4 hours to form a semi-dry mixed powder;

[0032] (3) Add the semi-dry mixed powder into an openable airtight container and shake it mechanically for 40 minutes to form a wet body sample;

[0033] (4) Dry the sample block at 100°C for 4 hours to obtain a porous solid sample block of the active ammonia storage mixture containing 11wt% carbon fibers.

[0034] Fill the 10g porous solid sample block with ammonia in a naturally ventilated environment. Put the openable airtight container in a water tank with enough cooling water in advance, connect the ammonia cylinder, and pass through the pressure reducing valve and the drying system. , fill ammonia slowly within the pressure range of 0.2Mpa, the ammonia filling time is 7h; after ammonia filling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com