Household garbage coupling fluidized bed grading pyrolysis gasification technology

A domestic waste, pyrolysis gasification technology, applied in the field of domestic waste coupled fluidized bed staged pyrolysis gasification technology, can solve the problems of complex oil components, difficulty in removing tar, difficult phenolic water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

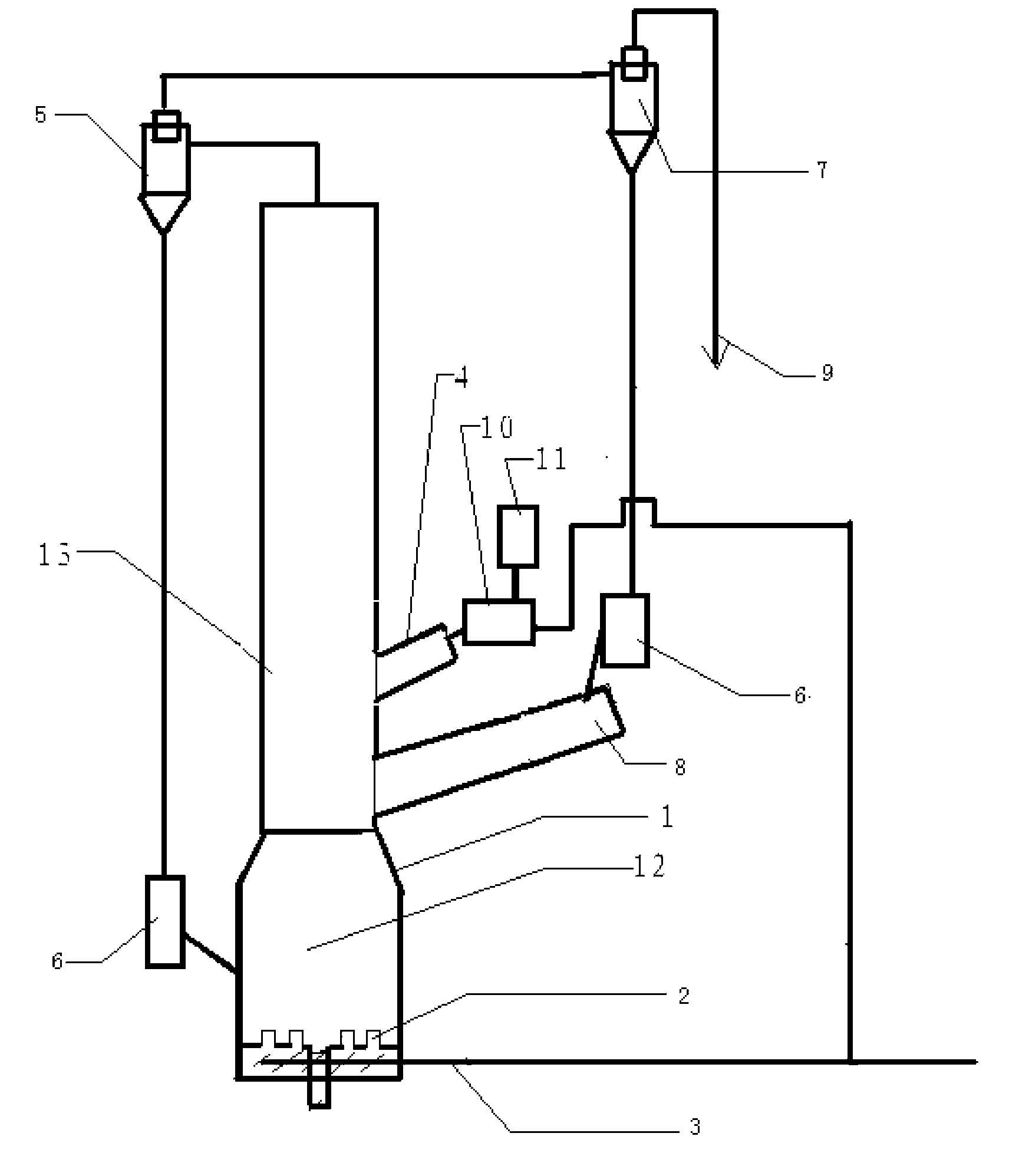

[0014] Example 1, the domestic waste is first deironed and pulverized by the deironing pulverizer (10), and then the 0-6mm garbage particles are dried by the sleeve type drum dryer (11), and the generated water vapor containing peculiar smell is hot As a part of the gasification agent, hot garbage particles and a small amount of heat carrier are sent to the middle and lower part of the entrained bed reactor (13) coupled with the fluidized bed (1), mixed with gasification gas and circulating ash, and lifted upwards for hydrogen pyrolysis. Two-stage gas-solid separation, the high-temperature crude semi-coke separated by the first-stage gas-solid separator (5) returns to the turbulent fluidized bed (12) at the bottom of the coupled fluidized bed (1) through the feeder (6), and is mixed with air and Water vapor reacts at 800-1100°C to generate gasification gas, which flows upward together with circulating ash to form material circulation; the high-temperature fine semi-coke separat...

Embodiment 2

[0015] Example 2, the domestic garbage is first deironed and pulverized by the deironing pulverizer (10), and then the 0-6mm garbage particles are dried by the sleeve type drum dryer (11), and the generated water vapor containing peculiar smell is hot As a part of the gasification agent, hot garbage particles and a small amount of heat carrier are sent to the middle and lower part of the entrained bed reactor (13) coupled with the fluidized bed (1), mixed with gasification gas and circulating ash, and lifted upwards for hydrogen pyrolysis. Two-stage gas-solid separation, the high-temperature crude semi-coke separated by the first-stage gas-solid separator (5) returns to the turbulent fluidized bed (12) at the bottom of the coupled fluidized bed (1) through the return device (6), and is mixed with oxygen and Water vapor reacts at 800-1100°C to generate gasification gas, which flows upward together with circulating ash to form material circulation; the high-temperature fine semi-...

Embodiment 3

[0016] Embodiment 3, the air in embodiment 1 is changed into oxygen-enriched air, other is identical.

[0017] The domestic waste coupling fluidized bed staged pyrolysis gasification process provided by the present invention not only rationally utilizes heat energy, eliminates tar in the gasification process, solves the problem of fly ash in fluidized bed gasification, and eliminates dioxin and Odor, high methane gas content, while the gas does not contain tar, does not produce phenol water; low oxygen consumption, high gasification efficiency, high gasification intensity, small equipment volume, low steel consumption, greatly reduced fixed investment, and exhaust emissions Ash process is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com