Four-dimensional adjusting platform for optical detection

An optical detection and adjustment stage technology, applied in the direction of using optical devices, measuring devices, measuring instrument components, etc., can solve the problems of reduced data reliability, small size of multi-dimensional adjustment platform table, interference fringe jitter, etc. Effects of Stability and Adjustment Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

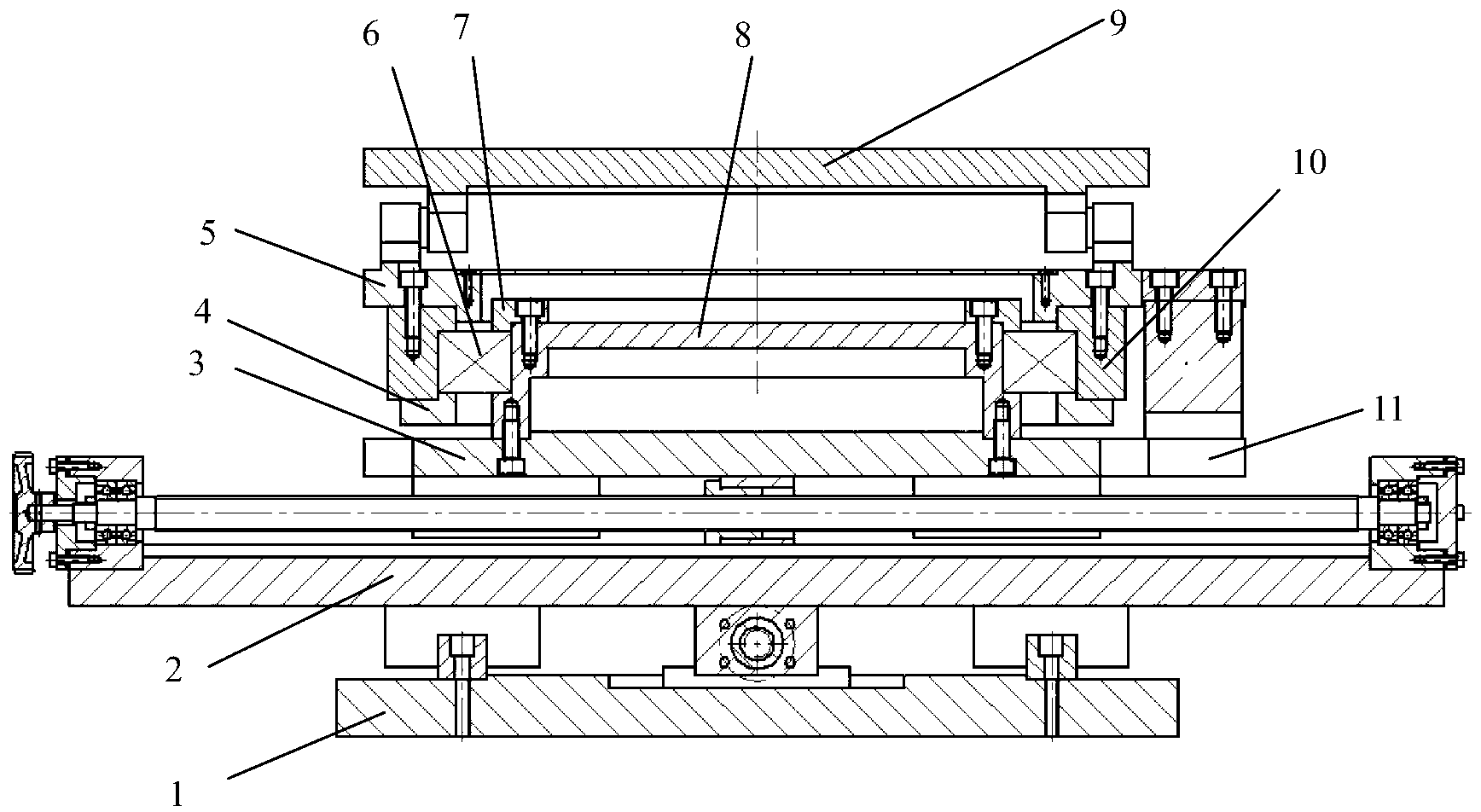

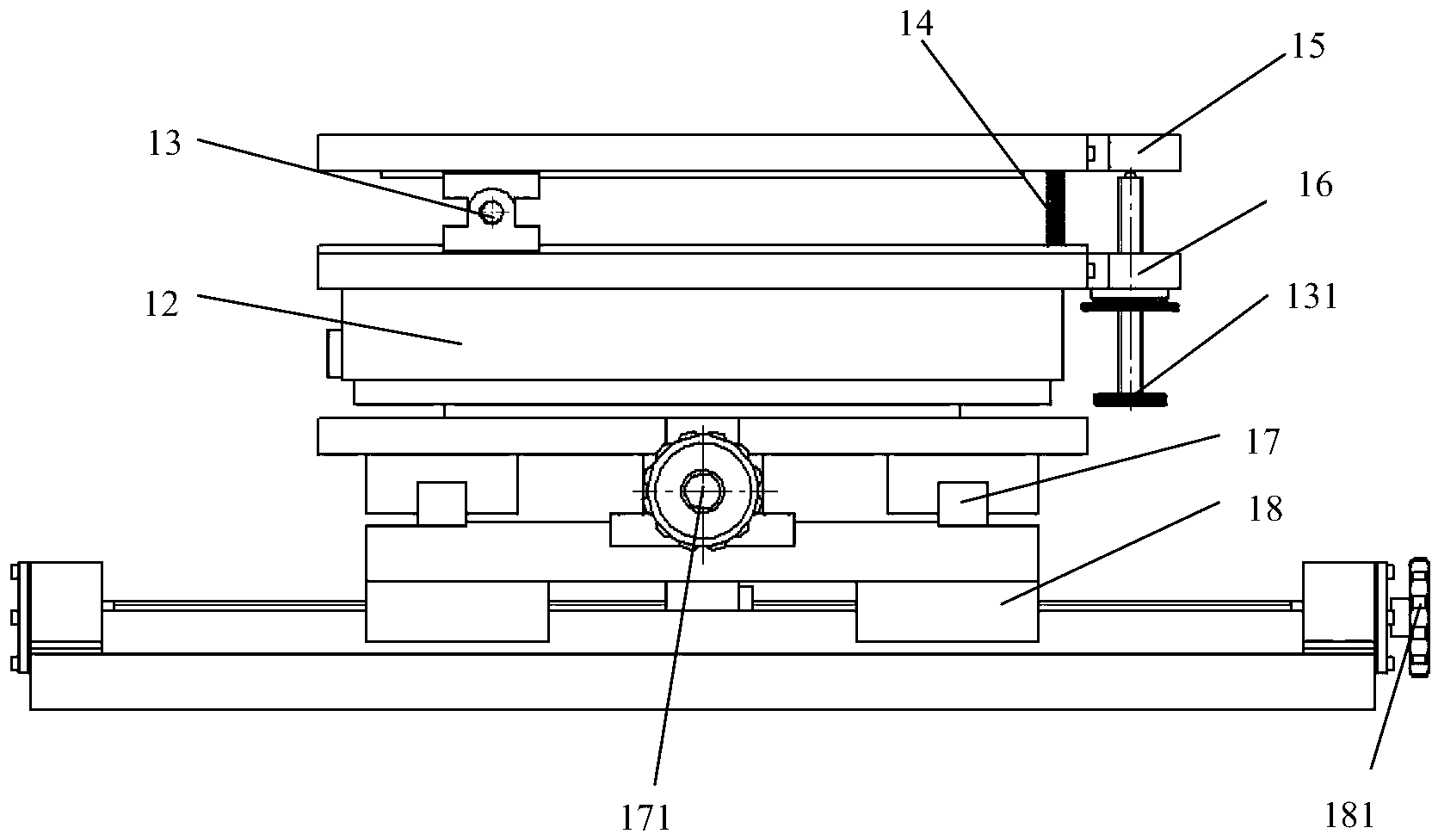

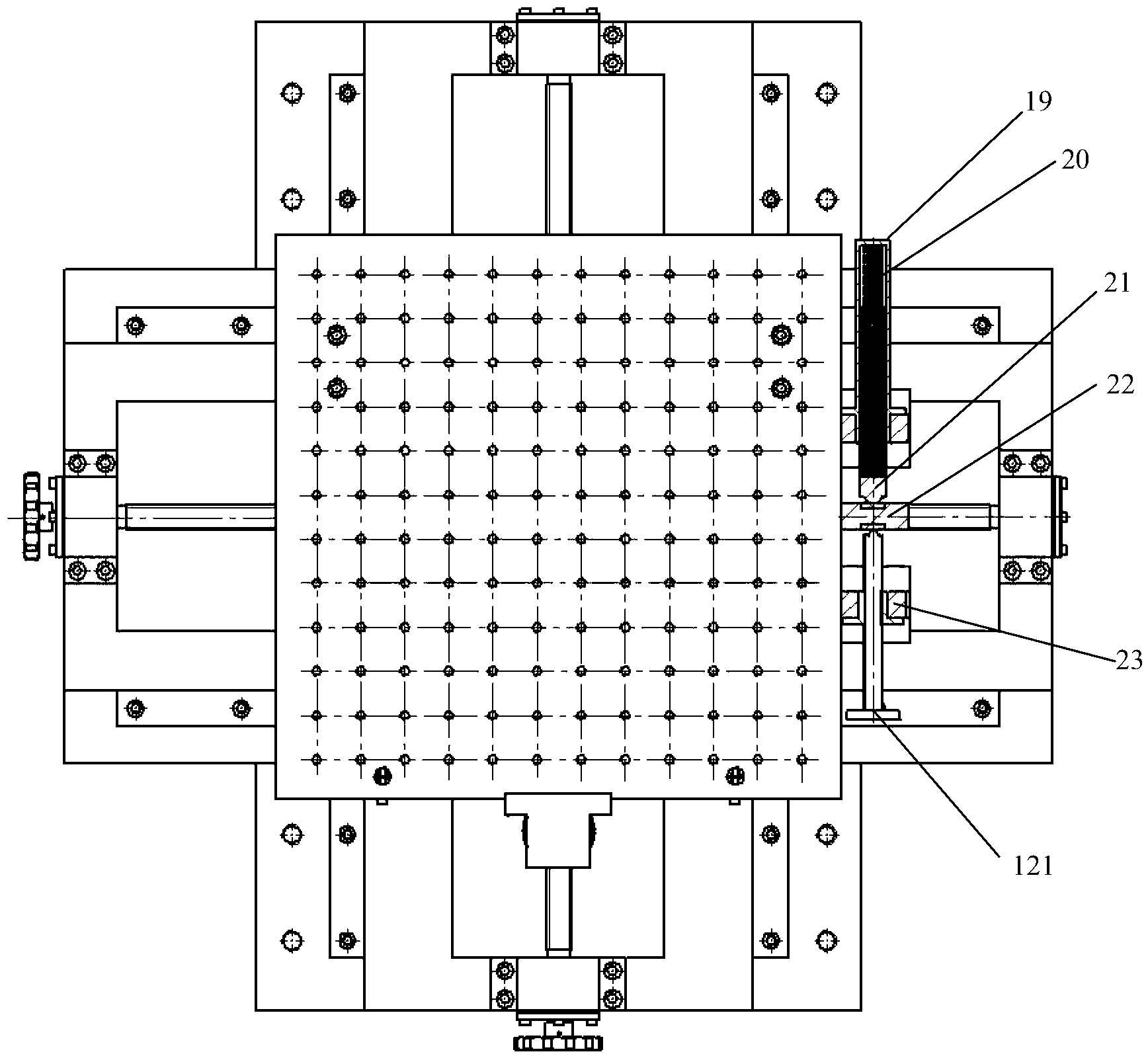

[0026] Such as Figure 1 to Figure 3 As shown, the spatial layout of the four-dimensional adjustment stage for optical detection can be divided into four layers from top to bottom, each of which undertakes different motion functions. The workbench and the pan / tilt are connected through the pitch joint to realize the adjustment of the pitch angle. The pitch joint is located at four-fifths of the total length of the workbench. It is always in close contact with the ball head of the adjusting screw; at the same time, there is a tension spring between the worktable and the cloud platform. The extension spring prevents virtual contact or overturning of the workbench even when it is used under extreme load conditions (the center of gravity of the load is seriously biased towards the end of the pitch joint). The pan-tilt and the lateral displacement platform are connected through a yaw joint, and the present invention preferably realizes the yaw movement through cross cylindrical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com