Post-desulphurization flue gas moisture content determination method and apparatus

A technology of flue gas after desulfurization and measurement device, which is applied in the field of chemical analysis, can solve the problems of inability to guarantee the accuracy of the test, difficulty in ensuring the condensation effect of the condenser, and the complexity of the measurement process, so as to improve the analysis efficiency and accuracy and save sampling and sample processing time, the effect of simplifying the analysis operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

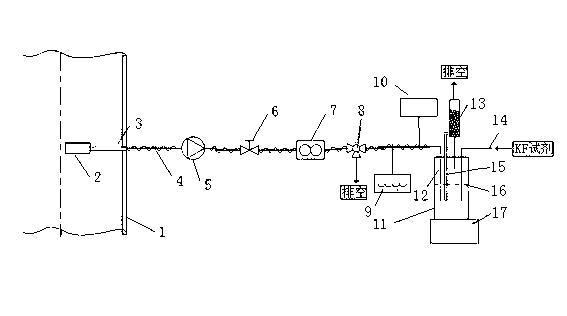

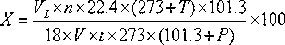

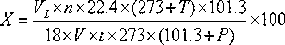

[0042] Example 1 Testing the moisture content of flue gas at the outlet of a desulfurization system of a 600MW unit

[0043] The flue gas enters the titration cup 11 of the Karl Fischer titrator through the sampling pipe 3, the heat tracing ventilation pipeline 4, the suction pump 5, the flow regulating valve 6, the flow meter 7, the three-way valve 8 and the intake pipe 12. method to measure.

[0044] (1) Measurement preparation: Add 100mL of anhydrous methanol to the titration cup 11 using the automatic suction and discharge system, turn the three-way valve 8 to the emptying position, and use the three-way valve to cut off the connection between the Karl Fischer titration system, the flue gas sampling system and the outside atmosphere . Start the titrator auto-balance function to reset the titrator to the system blank value. Preheat the heat tracing ventilation line 4. Anhydrous methanol is analytically pure anhydrous methanol.

[0045] (2) Calibration of Karl Fischer re...

Embodiment 2

[0051] Example 2 Testing the moisture content of flue gas at the outlet of a 300MW unit desulfurization system

[0052] (1) Measurement preparation: Add 100mL of anhydrous methanol to the titration cup 11 using the automatic suction and discharge system, turn the three-way valve 8 to the emptying position, and use the three-way valve to cut off the connection between the Karl Fischer titration system, the flue gas sampling system and the outside atmosphere . Start the titrator auto-balance function to reset the titrator to the system blank value. Adjust the temperature of the heating line to 130°C and preheat the sampling system. Anhydrous methanol is analytically pure anhydrous methanol.

[0053] (2) Accurately weigh 20 mg of standard water with a balance and pour it into the titration cup 11, start stirring, adjust the stirring speed, so that the methanol solution has obvious swirl but no air bubbles, titrate with Karl Fischer reagent, and the volume of Karl Fischer reagen...

Embodiment 3

[0059] Example 3 Test the moisture content of flue gas at the outlet of a 300MW unit desulfurization system (with flue gas heat exchanger)

[0060] (1) Measurement preparation: Add 100mL of anhydrous methanol into the titration cup 11 using the automatic suction and discharge system, turn the three-way valve 8 to the emptying position, and use the three-way valve 8 to cut off the connection between the Karl Fischer titration system, the flue gas sampling system and the outside atmosphere. connect. Start the titrator auto-balance function to reset the titrator to the system blank value. Adjust the temperature of the heating line to 120°C and preheat the sampling system. Anhydrous methanol is analytically pure anhydrous methanol.

[0061] (2) Accurately weigh 20 mg of standard water with a balance and pour it into the titration cup 11, start stirring, adjust the stirring speed, so that the methanol solution has obvious swirl but no air bubbles, titrate with Karl Fischer reagen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com