Online analysis method for gas components in natural gas hydrogen production process

An analysis method and technology of gas components, applied in the field of analysis of gas components, can solve the problems of complicated dehydration column regeneration, low sensitivity, unfavorable operation, etc., and achieve the goals of reducing analysis time, improving analysis efficiency, and optimizing analysis errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

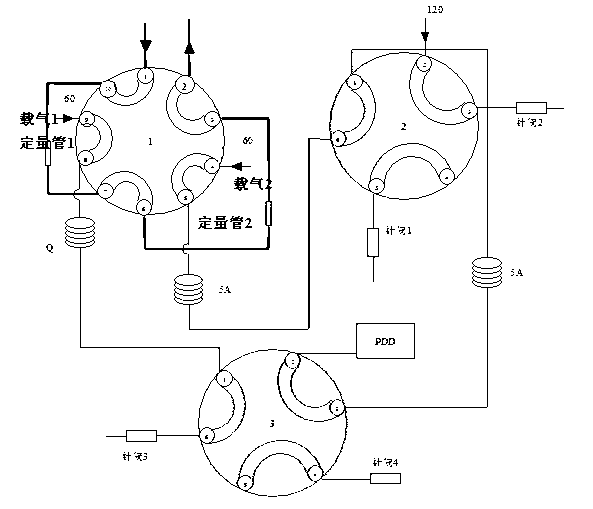

[0035] Below, refer to the attached figure 1 The present invention will be described.

[0036] 1. Analysis of 5N high-purity hydrogen

[0037] Use 5N high-purity hydrogen as a sample, and the sample enters the chromatograph at a flow rate of 0.1 MPa and 300 mL / min to replace the quantitative tubes (1) and (2) of the chromatograph. After 1 min of replacement, start the operating procedure. Send the sample gas in the quantitative tubes (1) and (2) to the Q column and 5A column I of the chromatograph respectively, and the Q column is vented through the needle valve 3 to remove CO 2 All components of the chromatograph then enter the PDD detector of the chromatograph to analyze the CO 2Impurity content. The 5A column I plays the role of pre-separation, and most of the main component H2 is emptied through the needle valve 1, but it is ensured that there is no loss of O2 in the sample gas, and then the remaining components are sent to the 5A column of the chromatograph by switchi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap