Method for determining matching relations among components in photoetching lighting system

A technology for lighting systems and matching relationships, applied in the field of determining matching relationships between components in lithography lighting systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

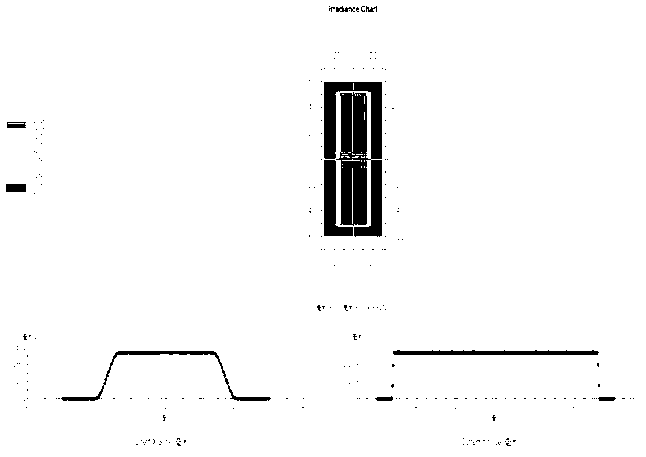

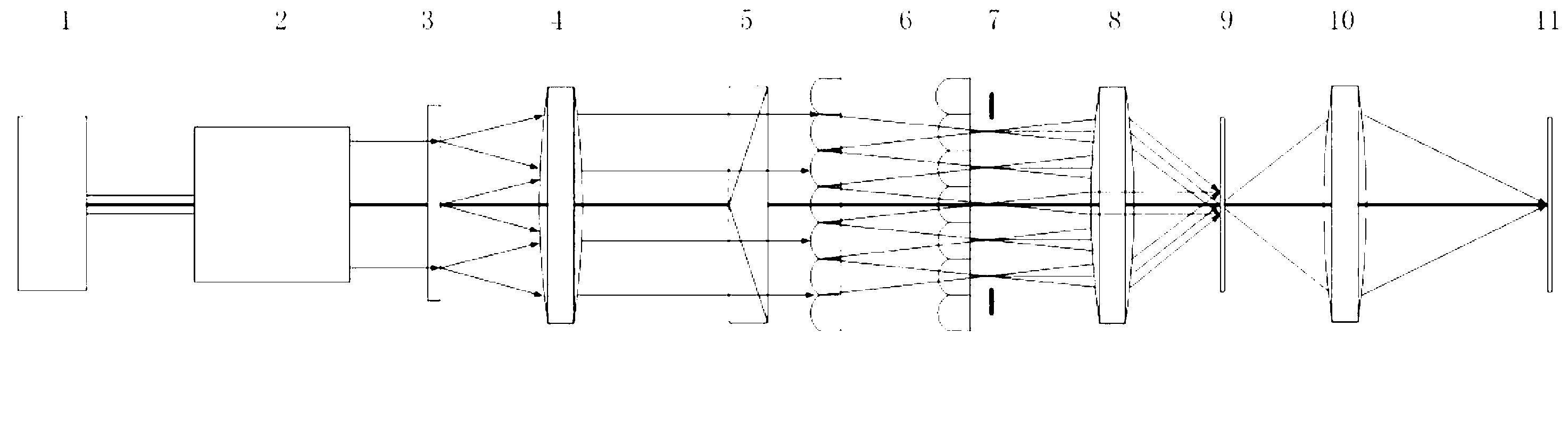

Image

Examples

Embodiment

[0043] There is an existing lithography lighting system, and its design requirements are listed in Table 1 as follows:

[0044] Table 1: Lithography illumination system requirements

[0045] Illumination image square NA

0.1875

Lighting area size

104mm×42mm

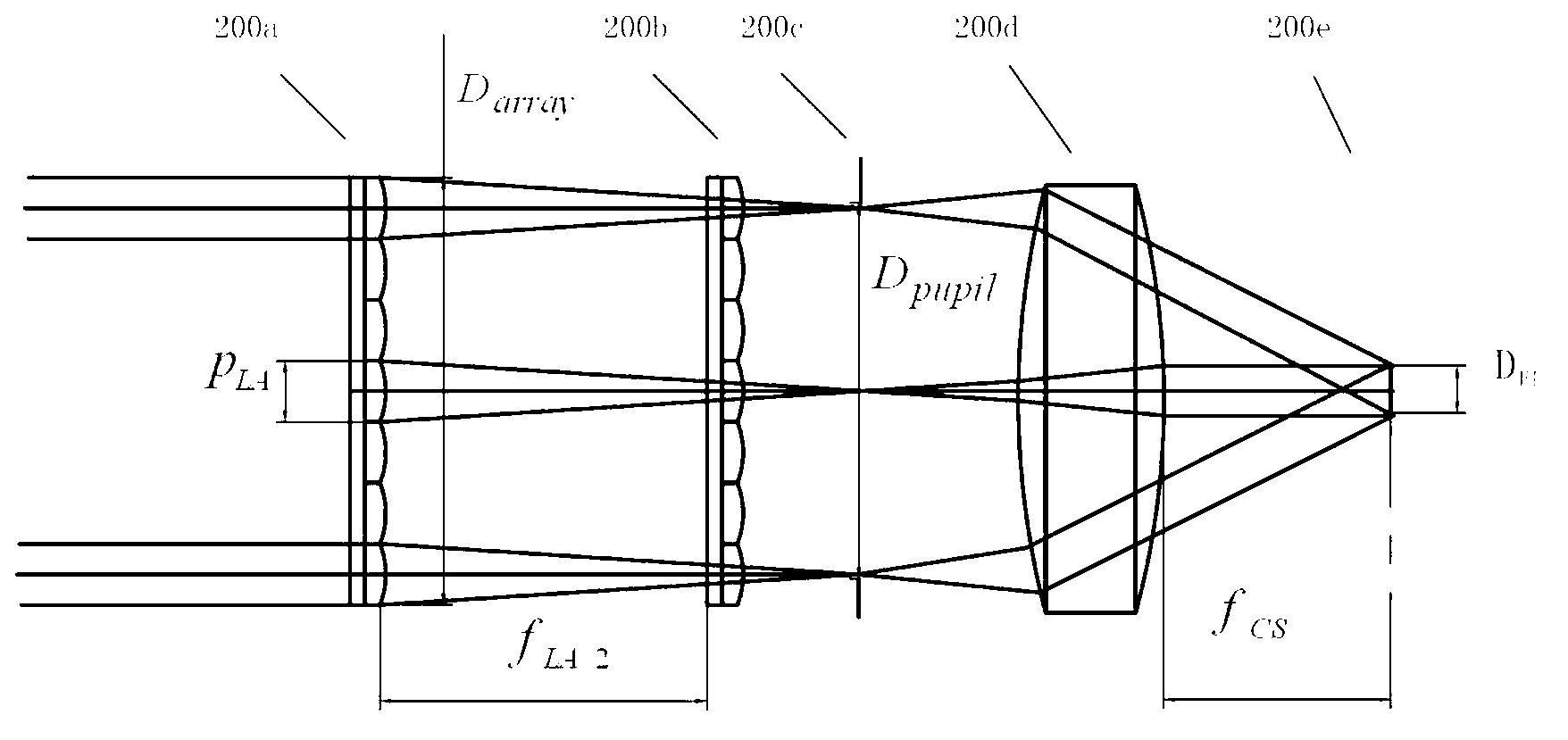

[0046] In this embodiment, firstly, the magnification of the steering mirror is selected to be 1×. Then the condenser lens NA=0.1875, the illumination area of the back focal plane of the condenser lens is 108mm×46mm, which is slightly larger than the mask illumination area, and at the same time, the partial coherence factor of the lithography illumination system σ=1.

[0047] According to the current processing situation of the microlens array, and according to the design method proposed in this patent, the specifications of the compound eye array are finally determined as shown in the following table:

[0048] Table 2: Specifications of Compound Eye Homogenizer

[0049]

[0050] Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com