Ion exchanging resin load-type heteropoly compound as well as preparation method and application thereof

A technology of ion exchange resins and heteropoly compounds, applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, chemical/physical processes, etc., can solve problems such as difficult recycling and reuse, and achieve easy recycling And reuse, reduce sulfur content, process cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of ion-exchange resin-supported heteropoly compounds (the ion-exchange resin used is: D296 macroporous strongly basic styrene-based anion-exchange resin)

[0030] Proceed as follows:

[0031] (1) Pretreatment of ion exchange resin:

[0032] (1) Take the ion exchange resin (D296 macroporous strongly basic styrene-based anion exchange resin) in a beaker, add distilled water and mechanically stir for 2 hours;

[0033] (2) Suction filter after stirring, wash with distilled water 4 times;

[0034] (3) Put the washed resin in 1.0mol / L NaOH solution and stir it mechanically for 1.5h;

[0035] (4) The alkali-treated resin is washed with distilled water until the pH value is near neutral (6.8-7.8);

[0036] (5) Put the washed resin in 1.0mol / L hydrochloric acid, and stir it mechanically for 2 hours;

[0037] (6) Wash the acid-treated resin with distilled water until the pH value is near neutral (6.8-7.8);

[0038] (7) Put the treated resin in an oven, ...

Embodiment 2

[0047] Example 2 Preparation of ion-exchange resin-supported heteropoly compounds (the ion-exchange resin used is: D001-CC macroporous strongly acidic styrene-based cation-exchange resin)

[0048] Proceed as follows:

[0049] (1) Pretreatment of the ion exchange resin (the pretreatment of the resin is the same as in Example 1).

[0050] (2) Preparation of ion-exchange resin-loaded heteropoly compound: Take 2.0g of the above-prepared ion-exchange resin, add it to a beaker containing 4.6g of phosphotungstic acid and 400ml of distilled water, and stir continuously at 60°C for 24h; after the loading is completed, Filter the ion-exchange resin with a Buchner funnel, wash it with distilled water, and then place it in an oven at 60°C for 24 hours to obtain the ion-exchange resin-loaded heteropoly compound. The final loading capacity was determined to be 95%, and it was stored for future use.

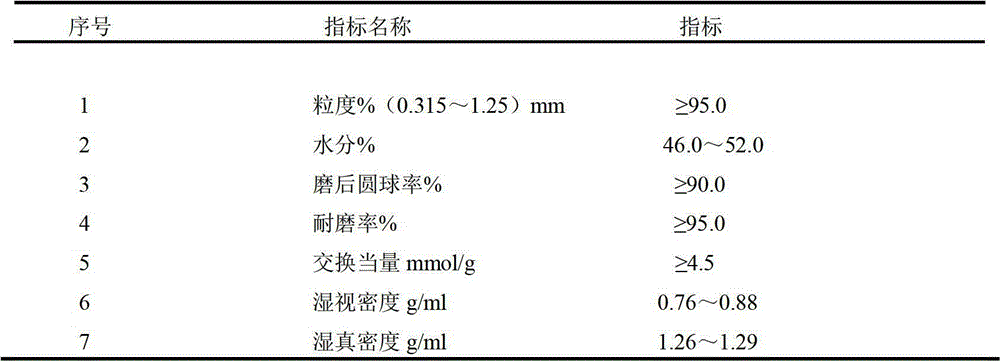

[0051] The kind and parameter of ion-exchange resin used in embodiment 2 are as shown in t...

Embodiment 3

[0058] Example 3 Preparation of ion-exchange resin-supported heteropoly compound (the ion-exchange resin used is: 201×7 type strongly basic styrene-based anion-exchange resin)

[0059] Proceed as follows:

[0060] (1) Pretreatment of the ion exchange resin (the pretreatment of the resin is the same as in Example 1).

[0061] (2) Preparation of ion-exchange resin-loaded heteropoly compound: Take 2.0g of the above-prepared ion-exchange resin, add it to a beaker containing 4.6g of phosphotungstic acid and 400ml of distilled water, and stir continuously at 60°C for 24h; after the loading is completed, Filter the ion-exchange resin with a Buchner funnel, wash it with distilled water, then place it in an oven, and bake it at 60°C for 24 hours to obtain the ion-exchange resin-loaded heteropoly compound. The final loading capacity was determined to be 108%, and it was stored for future use.

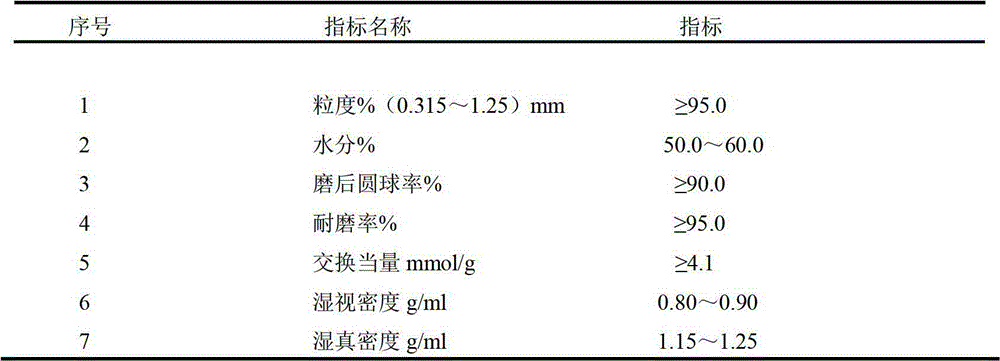

[0062] The kind and parameter of ion-exchange resin used in embodiment 3 are as shown in tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com