Wave force direct-driving hydraulic turbine

A water turbine and direct drive technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of high flow noise and low average efficiency, and achieve the effects of low noise, strong adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

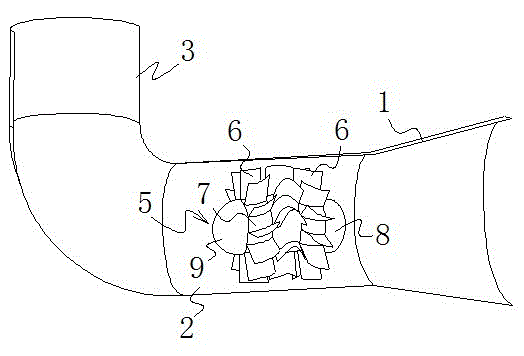

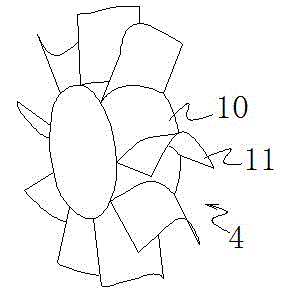

[0022] The present invention comprises an L-shaped body composed of a guide tube 1, a guide wheel tube 2 and a reservoir 3; the guide tube 1 is trumpet-shaped for capturing wave energy; The runner 4 that can be converted into electric energy and the guide body 5 for placing the engine unit. The outer wall of the runner hub 10 is evenly provided with a number of runner blades 11 along the circumference, and the outer wall of the guide body 5 is provided with a wave guide for guiding the wave to the runner. Several fixed guide vanes 6 on the blade 11 thereby drive the runner 4 to rotate; the reservoir 3 is cylindrical.

[0023] The guide body 5 includes a first hollow barrel 7 and a second hollow barrel 8, all of which are fixed in the guide wheel tube 2, and the runner 4 is arranged between the first hollow barrel 7 and the second hollow barrel 8; One end of the hollow barrel 7 and the second hollow barrel 8 is respectively fixed with a hemispherical top cover 9 . The runner b...

Embodiment 2

[0030] In this embodiment, the fixed guide vanes 6 adopt a pure flat plate shape without arc segments, and two sets of fixed guide vanes 6 are symmetrically divided in a figure-eight shape on both sides of the runner 4 . Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com