Fixing structure of water inlet pressure steel pipe of hydropower station

A technology for the powerhouse and water inlet pressure of a hydropower station is applied in the directions of pipes, hoses, etc., and can solve the problems such as the difficulty of installing concrete pouring for steel bifurcated pipes, the easy cracking of the concrete structure of the pier, and the impact on the service life of the pier. Good economic and social benefits, convenient installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

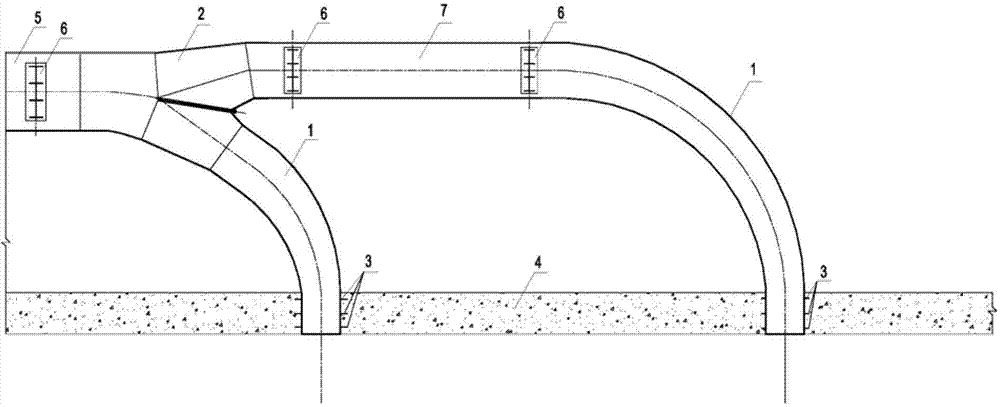

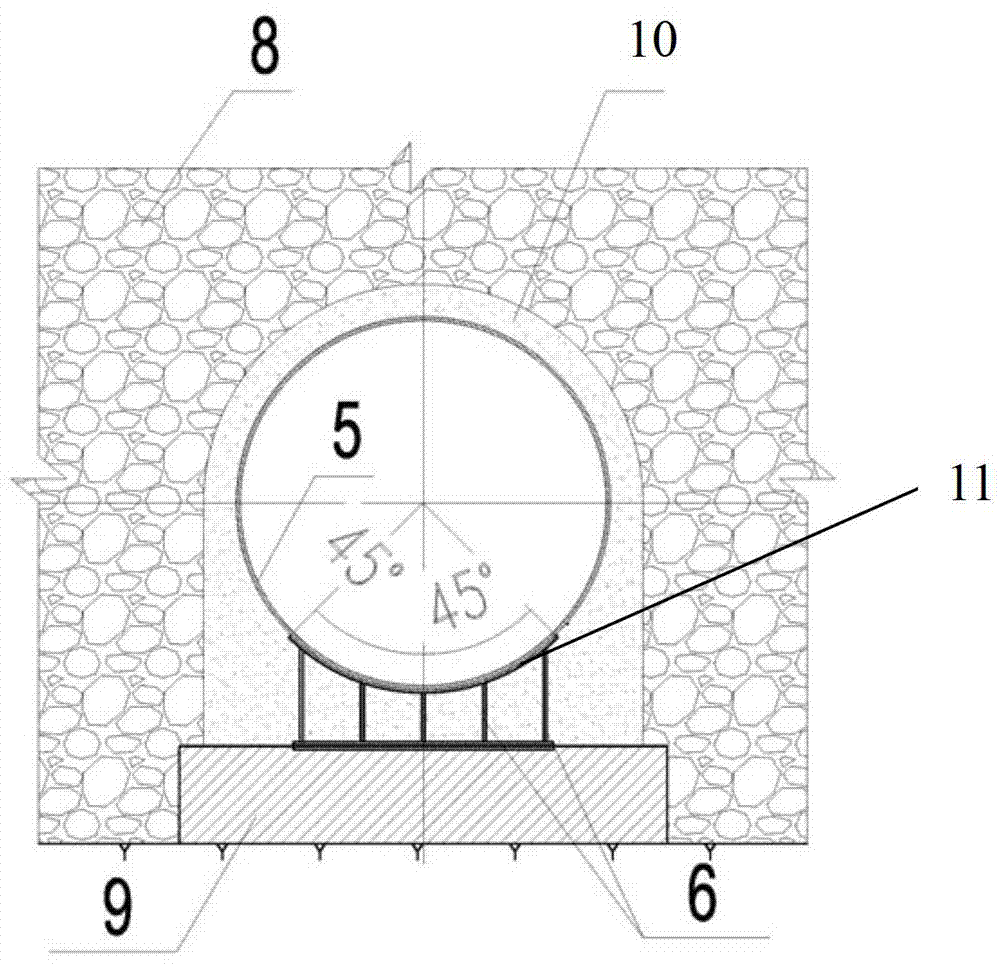

[0017] Such as figure 1 , 2 As shown, the fixed structure of the hydropower plant water inlet pressure steel pipe of the present invention includes a pressure steel pipe 5, a steel branch pipe 2 connected with the pressure steel pipe 5, a bend pipe 1 connected with the steel branch pipe 2, and a factory building embedded in the top of the bend pipe 1 The concrete wall 4 is characterized in that a sliding support 6 for limiting vertical displacement is set at the bottom of the penstock 5 straight pipe section, and a protective layer 10 backfilled with useful grade ingredients is arranged around the steel bifurcated pipe 2 and the bent pipe 3, and the periphery of the protective layer 10 is A heavy cover layer 8 is provided, and a ribbed ring 3 is provided on the periphery of the top end of the elbow 1 embedded in the concrete wall 4 of the facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com