Meter-bus data collector with ultra-low power loss

A data collector, counter bus technology, applied in instruments, comprehensive factory control, signal transmission systems, etc., can solve the problems of increased power loss, waste of resources, low data bus, etc., to reduce metering loss, reduce power consumption, collect Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

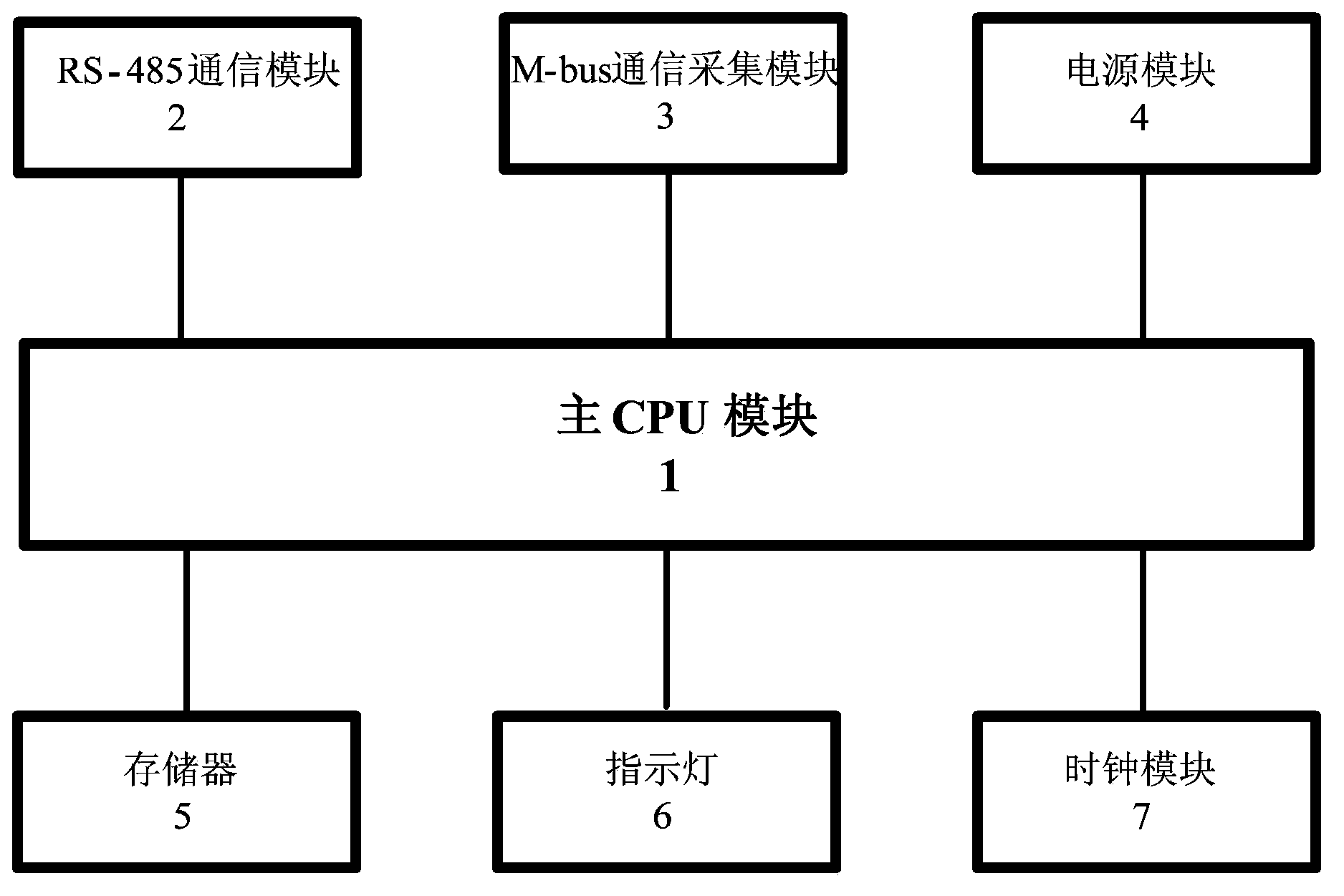

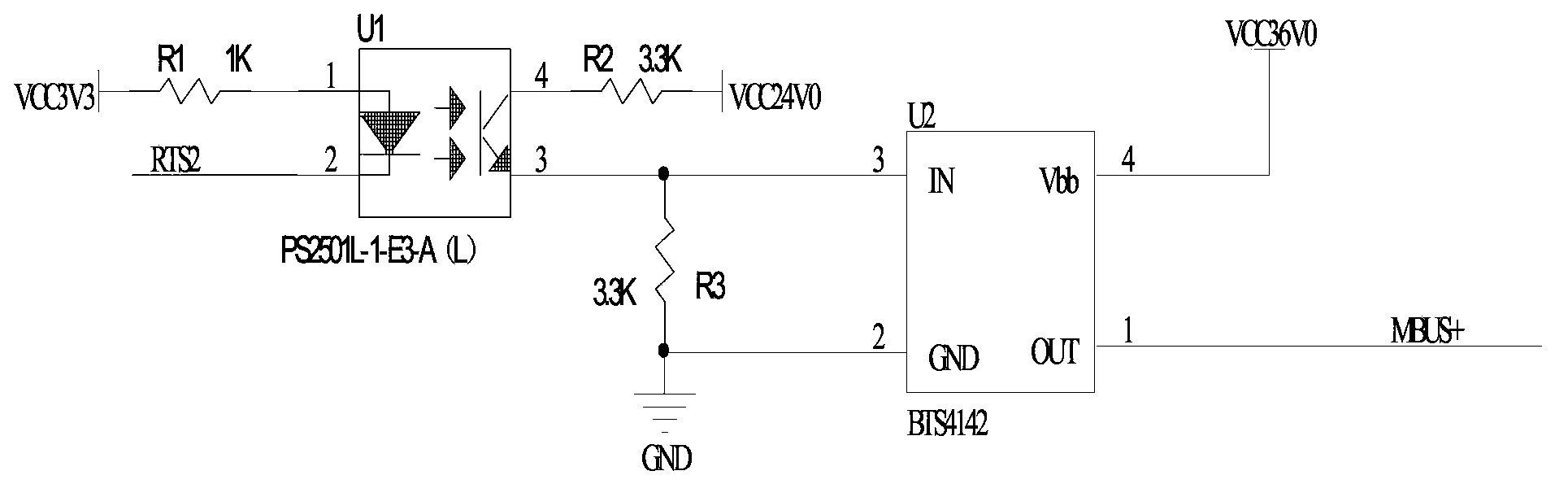

[0035] a kind of like Figure 1~2 The ultra-low power loss M-Bus data collector for energy management systems shown is connected to 64 meters, and the long-term operating power loss is less than 0.1W, which includes:

[0036]The main CPU module of the 16-bit FIash type MSP430 series ultra-low power loss single-chip microcomputer integrated with a UART chip is awakened by the clock module. Under the condition of 1.8-3.6V voltage and 1MHz clock condition, the power consumption current is within 400μA. The standby current in the acquisition state is only 2.6μA, and the wake-up time from the standby mode is only 6μs. It has extremely low power loss and high response speed, which can significantly reduce the power consumption of the whole machine. The main CPU module is used for the control of the module itself The signals provided by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com