Lubricating oil composition for reducing friction comprising nanoporous particles

A kind of lubricating oil composition, nanopore technology, applied in the direction of lubricating composition, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~56

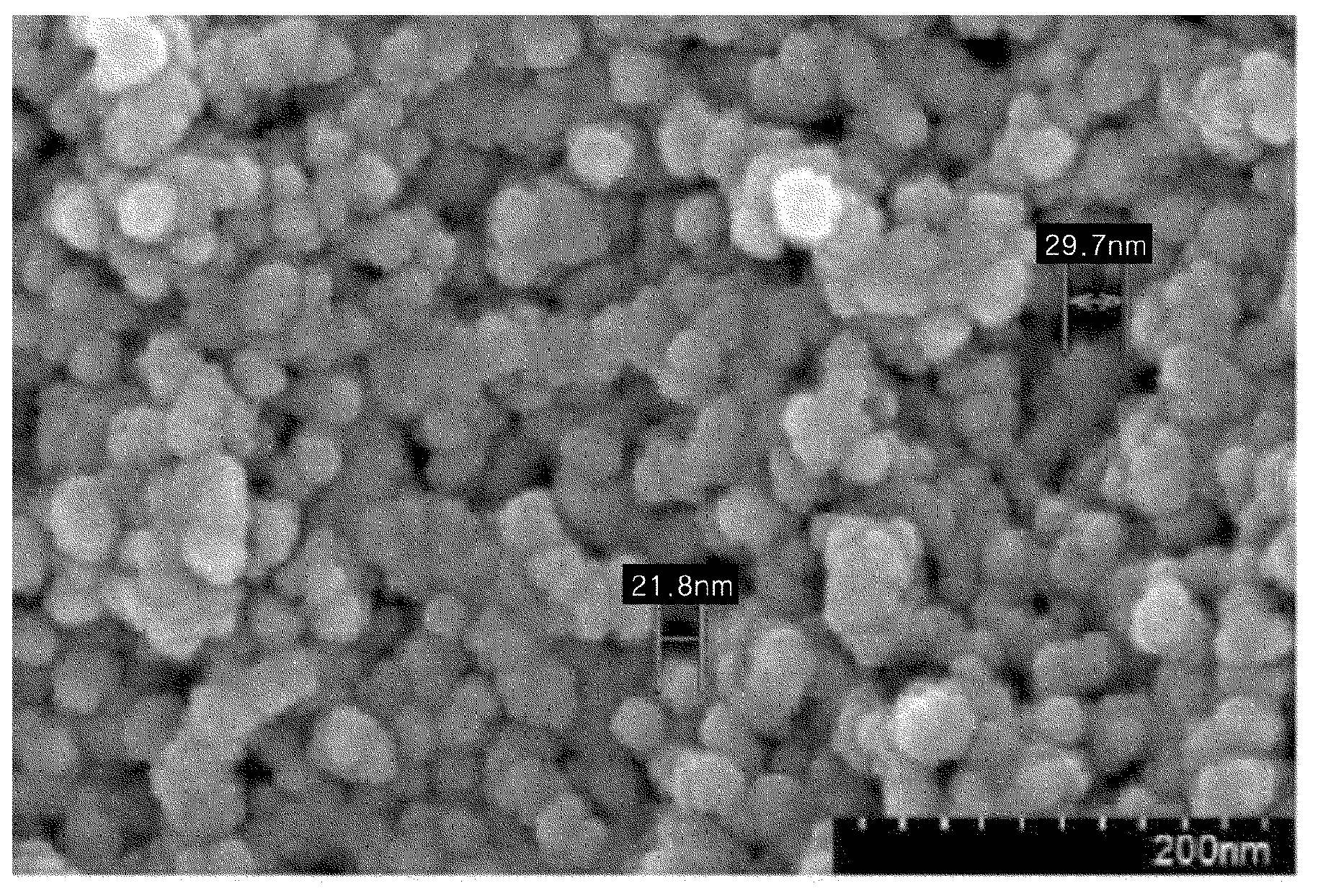

[0035] Examples 1-56. Preparation of lubricating oil compositions comprising nanoporous particles

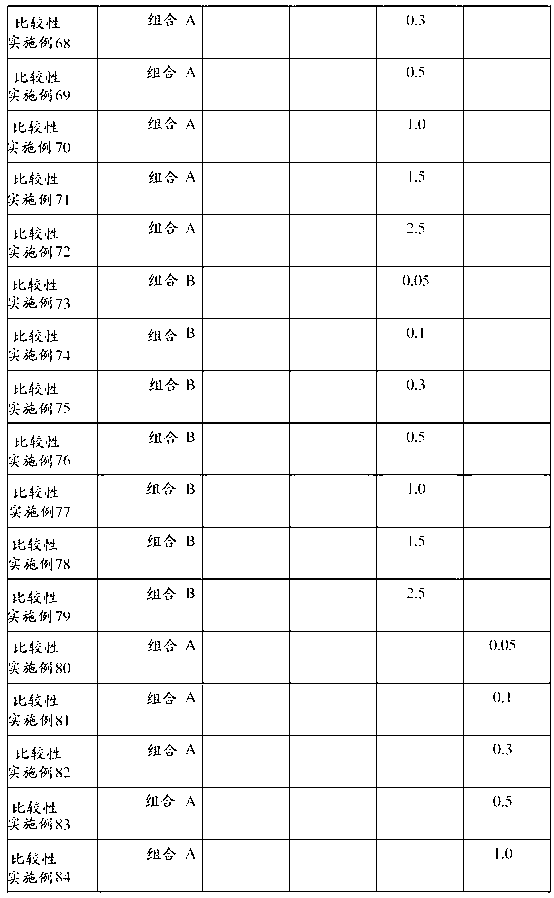

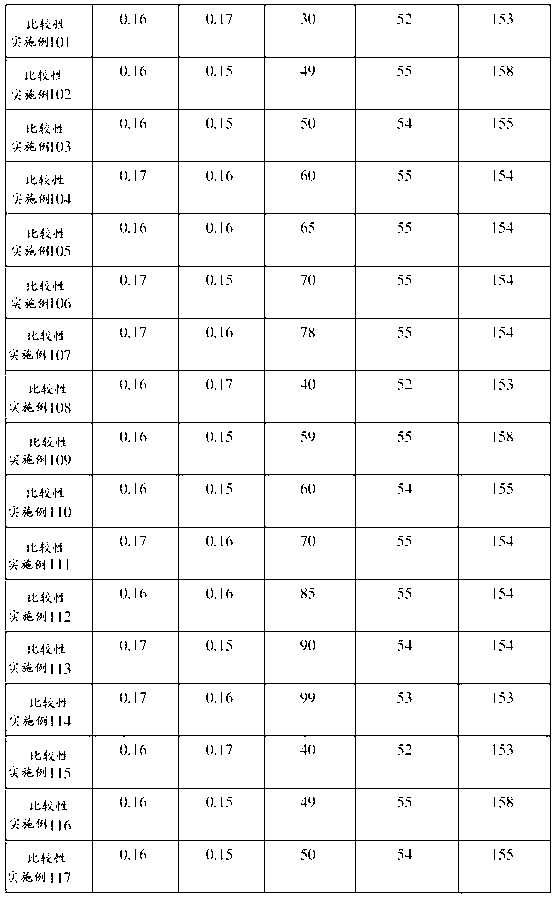

[0036] Lubricants were prepared with lubricant combinations A or B shown in Table 2. Nanoporous particles are prepared by converting silicon alkoxides to a gel type and drying with a supercritical fluid (eg, carbon dioxide). Next, the thus-prepared nanoporous particles were added in the amount of Table 3 based on 100 parts by weight of the lubricant, thereby preparing lubricating oil compositions of Examples 1 to 56.

[0037] Nanoporous silica was representatively prepared as follows. First 50ml TEOS (tetraethyl orthosilicate) was mixed with 40ml ethanol, followed by the addition of 35ml ethanol, 70ml water, 0.275ml 30% ammonia solution and 0.2ml 0.5M ammonium fluoride. Here, ammonia and ammonium fluoride are used as catalysts. The resulting solution was mixed thoroughly with gentle agitation to induce gelation, thereby forming an alkoxide gel. Gelation was carried out for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com