Super-hydrophobic material and preparation method thereof

A super-hydrophobic, matrix technology, applied in the direction of coatings, special surfaces, and devices for coating liquids on surfaces, can solve problems such as high cost, poor reliability, and unsuitability for glass surface treatment, and achieve low cost and excellent super-hydrophobic Performance, excellent anti-fingerprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a preparation method of ultra -hydrophobic material, which uses etching liquid to etch a micrometer or sub -micron structure on the surface of the substrate, and then forms nano -coating on the surface of the substrate surface with micrometer or sub -micron structure, so as to obtain the micro -nano structure of the ideal structureThen use a low -surface energy substance to modify the microfanan structure to obtain the ultra -hydrophobic material of the present invention. Specifically, the preparation method of the super hydrophobic material of the present invention, including the following steps:

[0030] Step 1. Use the etching solution to etch a micrometer or sub -micron structure on the surface of the substrate.

[0031] Micro -nano structures that prepare ultra -hydrophobic materials in existing technologies are usually set on the substrate to form a microfanan structure. 2 Granules and nano -level SIOs 2 The membrane layer of the particl...

Embodiment 1

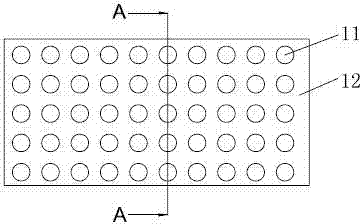

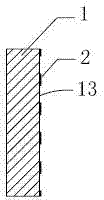

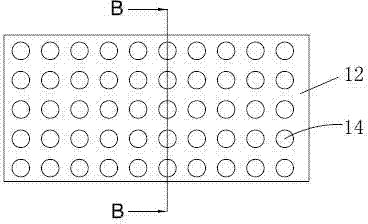

[0055] Reference Figure 1-4 , This Example 1 is used to prepare ultra -hydrophobic glass;

[0056] The preparation method of hydrophobic glass in this embodiment 1 includes the following steps:

[0057] Step 1, first clean and dry the size of the size of 84 × 56 × 1.1 mm (4inch), evenly apply 25 μm paraffin film 2 on the surface of the glass 1;The etching area 11, the remaining areas are set to the coverage area 12, using laser carving patterns on the paraffin film 2 to remove the paraffin on the carved area 11, such as figure 1 and figure 2 It shows that 11 to the eclipse area 11 includes several uniformly distributed naked areas 13. The naked area 13 is round, with a radius of 5 μm, and the round heart distance of the two adjacent naked areas 13 is 30 μm; the concentration of 20WT%is 20WT%The surface of hydrogen fluoric acid water solution corrodes the glass surface, corrodes 5 minutes at room temperature (25 ° C), and the carved carved liquid corrodes without paraffin protectio...

Embodiment 2

[0061] The preparation method of the ultra -sparse glass of this embodiment 2 includes the following steps:

[0062] Step 1. First, clean and dry the size of the size of 95 × 53 × 1 mm (4.3inch), and evenly apply 20 μm paraffin film on the surface of the glass; set the area of the glass surface to be etched to etch to etched engravedThe area, the rest of the area is set in the coverage area, using laser carving patterns on the paraffin film to remove paraffin to the etching area.6500 μm 2 , The center distance of the two adjacent naked areas is 120 μm; the surface of the glass surface with a concentration of 25WT%of the hydrofluoric acid water is corroded, and the heating conditions (50 ° C) are corroded for 1min.An groove, the cross section of the groove is positive hexagonal, with an area of 6500 μm 2 The depth is 1 μm, the center distance of the two adjacent grooves is 120 μm, and then the paraffin in the coverage area is washed and dried to form a micron structure;

[0063] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com