Film rolling machine with horizontally parallel ceramic rollers for pole pieces of lithium batteries

A technology of ceramics and rolls, applied in the field of horizontally parallel lithium battery pole piece film rolling machines with ceramic rolls, can solve problems such as floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

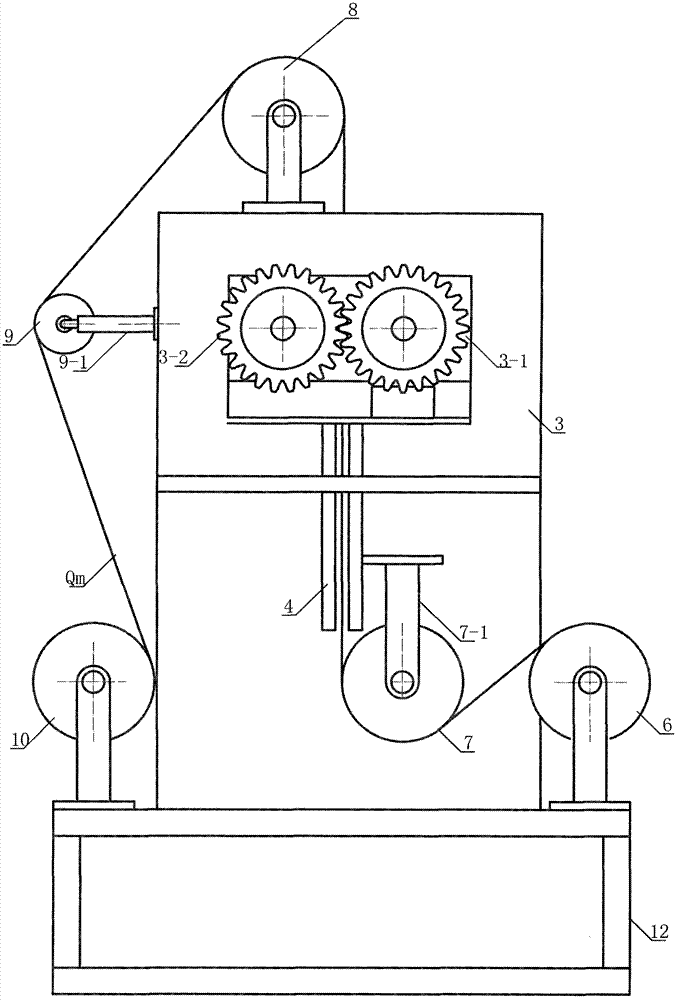

[0045] refer to Figure 5 , the pole piece Qm is sent out from the reel 6, and after the tension is adjusted by the roll tension roller 7, it is sent to the heater 4 in the two boxes for heating, so that the colloidal substance in the pole piece Qm is heated and softened, and then sent to the ceramic roll 3b and the ceramic roller 3b after being heated. The gap between the rollers 3a rolls the film, and the pole piece Qm rolls the film, and then passes the pole piece through the roll 8 and sends it to the winding tension roll 9, and reaches the winding drum 10 for winding.

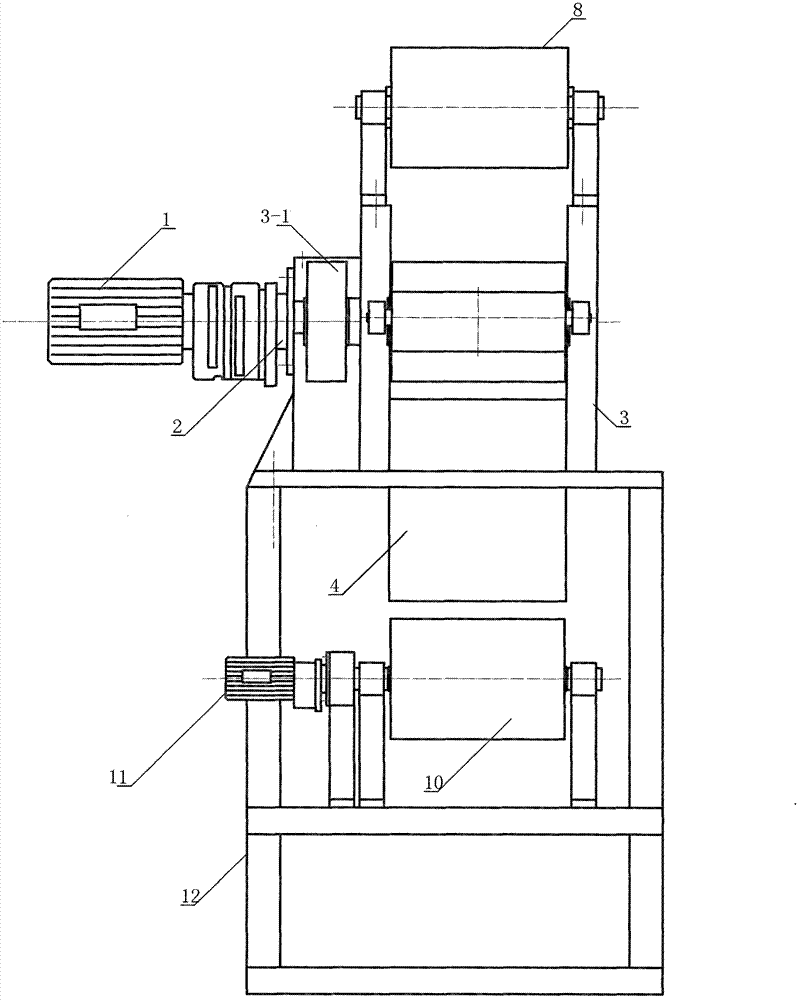

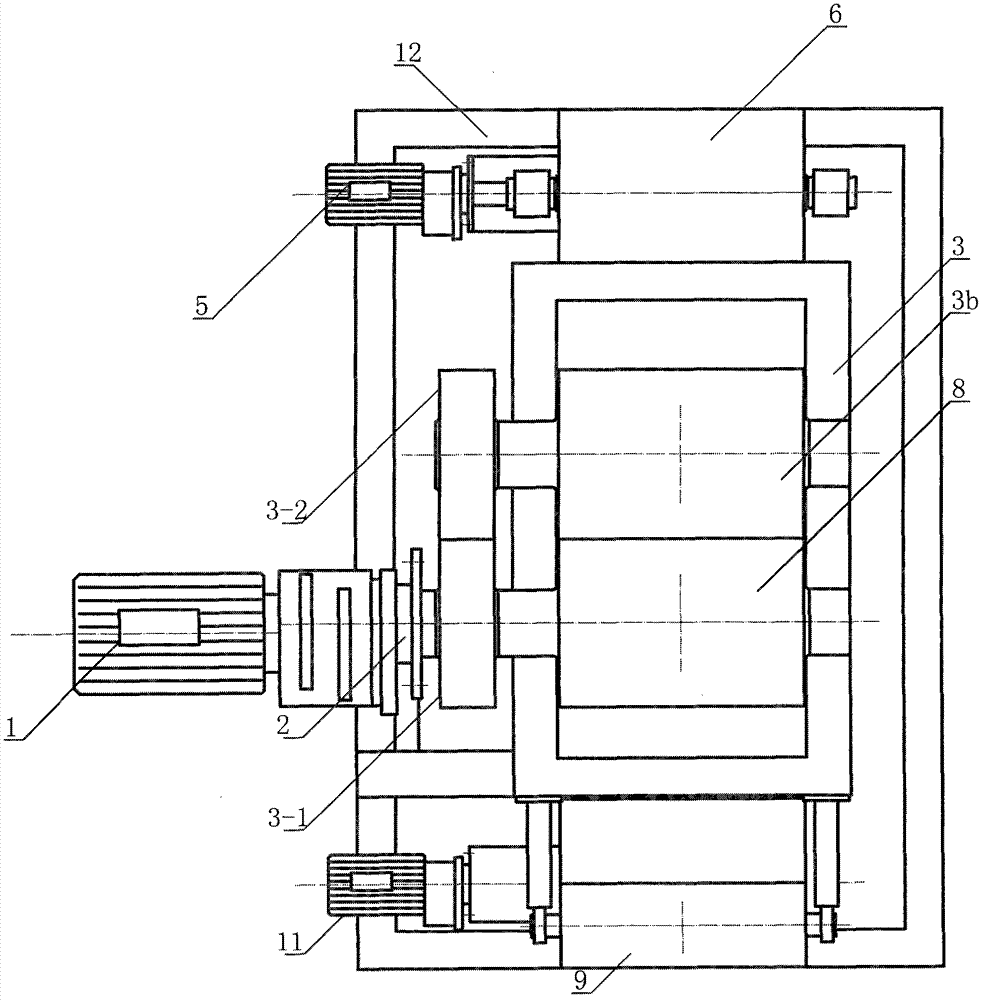

[0046] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , reducer motor 1, connecting coupling 2, connecting with driving gear 3-1, driving gear 3-1 meshing with driven gear 3-2 for synchronous transmission, driving gear 3-1 connected with ceramic roll 3a, driven gear 3 -2 ceramic rolls 3b are connected, the reduction motor 1 starts to rotate and drives the ceramic rolls 3a and the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com