Visual detection method of longitudinal tear of conveying belt

A technology of longitudinal tearing and visual detection, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of image quality and real-time performance, cannot adapt to long-term real-time applications, ultrasonic detection equipment Too many problems, etc., to achieve the effect of easy post-processing, fast response time and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

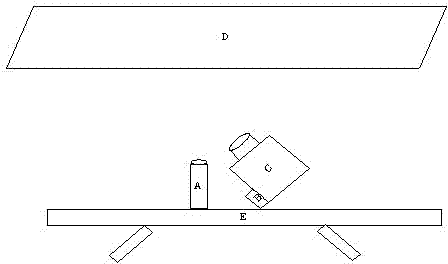

[0021] figure 1 It is an instrument diagram showing the visual detection method of longitudinal tearing of conveyor belt based on infrared CCD camera, and the instrument is installed according to this diagram.

[0022] Adjust the focal length of the infrared CCD camera so that the captured pictures can only be captured and can only capture the complete conveyor belt width. Program the single-chip microcomputer to realize the control of the infrared CCD camera's timing and triggering photography methods, and timing photography The time interval is 5 minutes to prevent the failure of the pyroelectric detector and cause missed judgments. The triggering of the photo is when the pyroelectric detector senses a rapid temperature change on the conveyor belt and generates a transient voltage. The transient voltage triggers the single-chip microcomputer. The single-chip microcomputer Trigger the infrared CCD camera switch, and the infrared CCD camera takes pictures.

[0023] Image proc...

Embodiment approach 2

[0031] The time interval for taking pictures at regular intervals is 4 minutes, and the others are the same as in Embodiment 1.

Embodiment approach 3

[0033] The time interval for taking pictures at regular intervals is 6 minutes, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com