Surface treatment method for titanium sponge reactor

A technology of surface treatment and sponge titanium, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of incomplete and uniform titanium infiltration layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

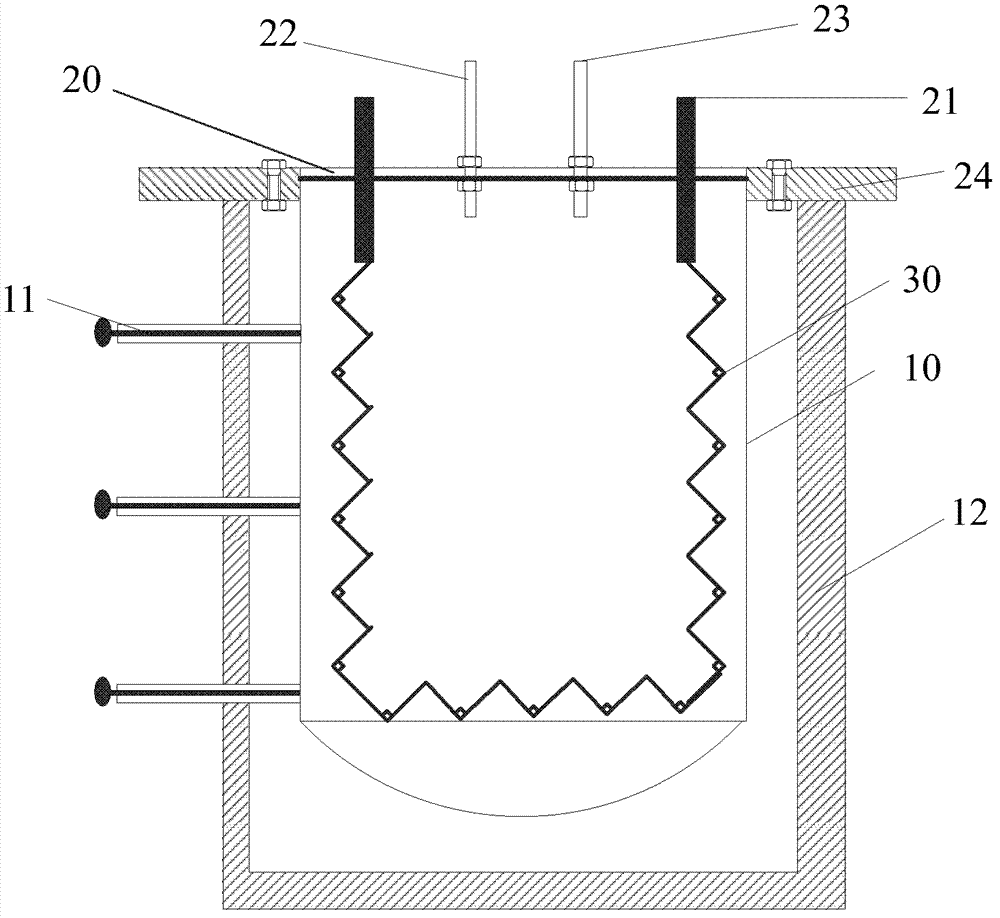

Embodiment 1

[0060] The tank body (brand 1Cr18Ni9Ti, vertical type, inner diameter 0.18m, inner surface area 2.12m 2 , made of stainless steel), the inner wall is pickled, washed and dried, and connected to the cover used for the titanium sponge reactor through a flange. The cover is provided with two electrodes, and a titanium wire (the titanium content is greater than 98% by weight, with a total weight of 2000g and a diameter of 5mm) is connected between the two electrodes. The inner surface of the tank body is uniformly distributed, and the distance between the inner surface of the tank body of the sponge titanium reactor and the nearest point of the titanium wire is 0.9 cm. A gas inlet and a gas outlet are also arranged on the cover of the reactor.

[0061] Through the gas outlet, use a vacuum pump to reduce the pressure in the tank of the sponge titanium reactor to below 1Pa and stabilize it to 0.5Pa. Then under 0.5Pa, energize the titanium wire (the initial voltage is 15V, and the ...

Embodiment 2

[0064] The tank body (brand 1Cr18Ni9Ti, vertical type, inner diameter 0.18m, inner surface area 2.12m 2 , made of stainless steel), the inner wall is pickled, washed and dried, and connected to the cover used for the titanium sponge reactor through a flange. Two electrodes are arranged on the cover, and titanium wire (the titanium content is greater than 98% by weight, with a total weight of 2000g and a diameter of 5mm) is connected between the two electrodes. The inner surface of the tank body is uniformly distributed, and the distance between the inner surface of the tank body of the sponge titanium reactor and the nearest point of the titanium wire is 0.3 cm. A gas inlet and a gas outlet are also arranged on the cover of the reactor.

[0065]Through the gas outlet, use a vacuum pump to reduce the pressure in the tank of the titanium sponge reactor to below 1Pa and stabilize it to 0.7Pa. Then under 0.7Pa, energize the titanium wire (the initial voltage is 15V, and the init...

Embodiment 3

[0068] The tank body (brand 1Cr18Ni9Ti, vertical type, inner diameter 0.18m, inner surface area 2.12m 2 , made of stainless steel), the inner wall is pickled, washed and dried, and connected to the cover used for the titanium sponge reactor through a flange. The cover is provided with two electrodes, and a titanium wire (the titanium content is greater than 98% by weight, with a total weight of 2000g and a diameter of 5mm) is connected between the two electrodes. The inner surface of the tank body is uniformly distributed, and the distance between the inner surface of the tank body of the sponge titanium reactor and the nearest point of the titanium wire is 1.5 cm. A gas inlet and a gas outlet are also arranged on the cover of the reactor.

[0069] Through the gas outlet, use a vacuum pump to reduce the pressure in the tank of the sponge titanium reactor to below 1Pa and stabilize it to 0.2Pa. Then under 0.2Pa, energize the titanium wire (the initial voltage is 15V, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com