Method and device for bottom drainage and seepage of film-laying anti-seepage phosphogypsum yard

A phosphogypsum and storage yard technology, which is applied in the direction of protection devices, water supply devices, and sewage discharge, can solve the problems of reduced mechanical properties of phosphogypsum, inability to drain and consolidate phosphogypsum, and unfavorable stability of phosphogypsum, so as to speed up drainage and solidification. Knot, prevent clogging, ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

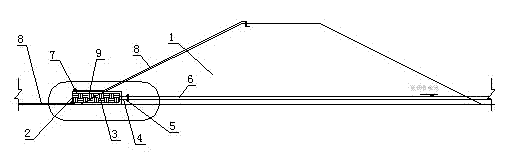

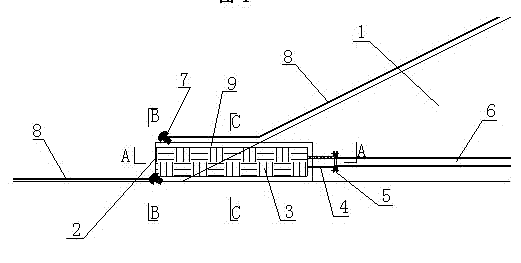

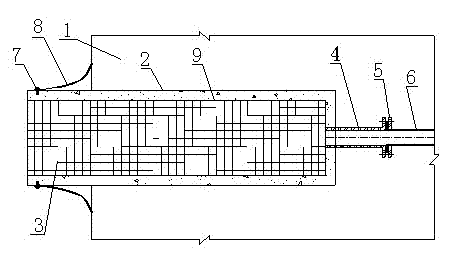

[0022] A method and device for drainage of seepage at the bottom of a film-laying anti-seepage phosphogypsum stockyard of the present invention, such as figure 1 and figure 2 shown. The device of the present invention is mainly composed of reinforced concrete box culvert 2, stainless steel pipe 4 and HDPE pipe 6. The reinforced concrete box culvert 2 is constructed together with the initial dam 1. After the reinforced concrete box culvert 2 reaches the design strength, the rolling construction of the initial dam can only be carried out after a 2m thick protective layer is stacked on the top of the reinforced concrete box culvert 2. The inner side of the reinforced concrete box culvert 2 and the parts outside the initial dam 1 need to be anti-corrosion with glass fiber reinforced plastic 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com