True triaxial test ultrasonic wave and acoustic emission testing system and testing method thereof

A test system and test method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that the nature and size of the acoustic emission source cannot be given, ultrasonic waves cannot propagate, and coupling is not achieved Test and other issues to avoid adverse effects, ensure normal transmission and reception, and protect the transducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

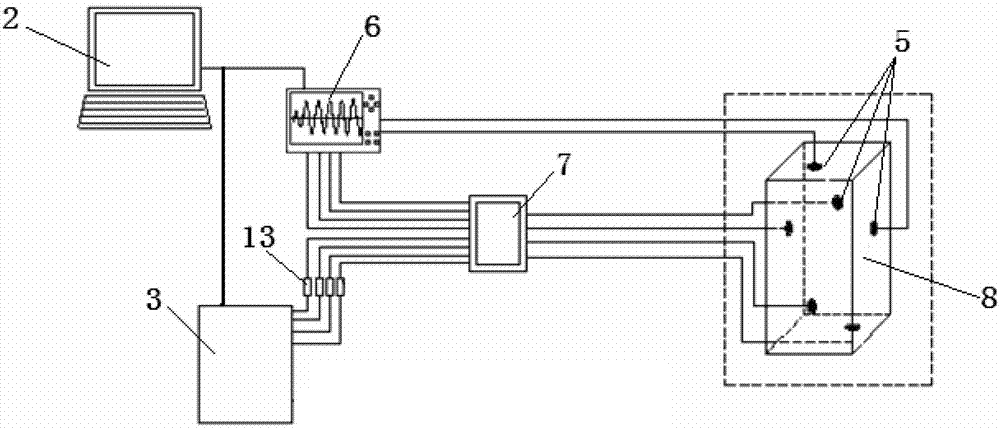

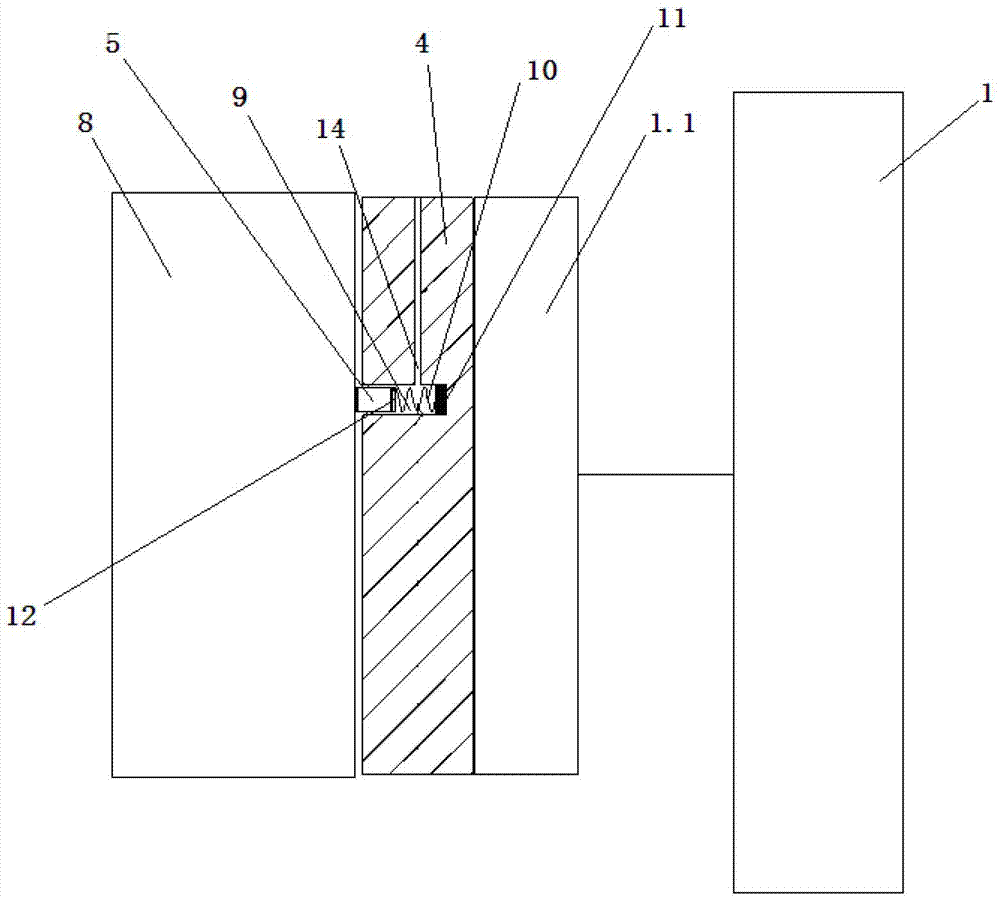

[0028] Such as figure 1 and 2The shown true triaxial test ultrasonic and acoustic emission testing system includes true triaxial test device 1, computer 2, acoustic emission instrument 3, ultrasonic and acoustic emission coupling test transducer 5, multi-channel ultrasonic flaw detector 6 and signal shunt 7, wherein, the true triaxial test device 1 has six pressure units 1.1, each surface pressure unit 1.1 and the corresponding surface of the rock block 8 is provided with an ultrasonic and acoustic emission coupling test transducer 5, at least one The communication end of the ultrasonic and acoustic emission coupling test transducer 5 is connected to the signal output end of the multi-channel ultrasonic flaw detector 6, and the communication ends of the rest of the ultrasonic and acoustic emission coupling test transducer 5 are respectively connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com