Compound sweetening agent suitable to be used in sour maize juice and preparation method thereof

A compound sweetener and corn juice technology, which is applied in the field of food additives, can solve the problems of increased product cost, difficult to cover aftertaste, heavy aftertaste, etc., and achieve the effects of improving sweetness dispersion, shortening the processing cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

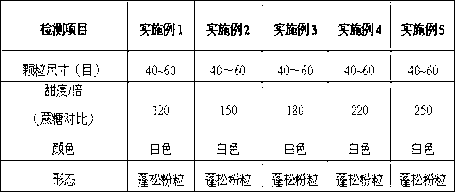

Examples

preparation example Construction

[0021] The preparation process of the compound sweetener: first put neotame, erythritol and maltodextrin accounting for 50-70% of the total amount into the multi-dimensional mixer, and mix at 600-1000rpm for 20-40 minutes to control the mixture The particle size of the material is 80~130 mesh, and the mixed material of neotame, erythritol and maltodextrin is obtained; then 2-(4-methoxyphenoxy)-sodium propionate, β-cyclodextrin, Salt and the remaining amount of maltodextrin are dissolved in deionized water to obtain a mixed aqueous solution; the resulting mixed material is put into the spray fluidized bed equipment, and the mixed material enters the fluidized bed from the bottom of the spray fluidized bed under positive pressure And the flow is accelerated from bottom to top, and the upper part of the spray fluidized bed is subjected to negative pressure to vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed. Small sugar alcohol particles...

Embodiment 1

[0024] (1) Put 1.5 kg of neotame, 35 kg of erythritol and 29.4 kg of maltodextrin into a multidimensional mixer, control the number of stages of the multidimensional mixer to 800 rpm, and mix for 30 minutes to obtain neotame, erythritol and The mixed material of maltodextrin, the particle size is between 80 and 130 mesh;

[0025] (2) Mix 5 kg of 2-(4-methoxyphenoxy)-sodium propionate, 3 kg of β-cyclodextrin, 6.5 kg of salt, and 19.6 kg of remaining maltodextrin with deionized water, heat up and stir Dissolved to obtain a mixed aqueous solution;

[0026] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the fluidiz...

Embodiment 2

[0028] (1) Put 1.875 kg of neotame, 36 kg of erythritol and 26.775 kg of maltodextrin into a multidimensional mixer, control the number of stages of the multidimensional mixer to 800rpm, and mix for 30 minutes to obtain neotame, erythritol and The mixed material of maltodextrin, the particle size is between 80 and 130 mesh;

[0029] (2) Mix 6 kg of 2-(4-methoxyphenoxy)-sodium propionate, 4 kg of β-cyclodextrin, 7.5 kg of salt, and 17.85 kg of remaining maltodextrin with deionized water, heat up and stir Dissolved to obtain a mixed aqueous solution;

[0030](3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com