Compound sweetener applied to sour soybean milk and preparation method thereof

A compound sweetener and sour soy milk technology, which is applied in the field of food additives, can solve the problems of heavy aftertaste, hard to cover aftertaste, and large loss of raw materials, and achieve the effects of reducing production costs, shortening the processing cycle, and uniformly dispersing sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

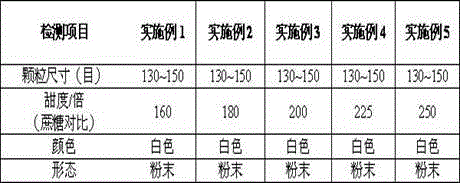

Examples

preparation example Construction

[0022] The preparation process of the compound sweetener: first put neotame, acesulfame potassium, erythritol and 20-30% of the total amount of maltitol into the multi-dimensional mixer, and mix at 600-1000rpm for 15-30 minutes; Then add 2-(4-methoxyphenoxy)-sodium propionate, β-cyclodextrin, carboxymethyl cellulose and the remaining amount of maltitol to the mixed material, and continue to mix at a rate of 600~1000rpm Mix for 20 to 50 minutes; discharge and pack into bags to obtain a compound sweetener.

[0023] The multidimensional mixer used in the present invention adopts a commercially available 200-kilogram multidimensional mixer with a speed range of 200 to 1800 rpm. The barrel is conical at both ends and columnar in the middle. Clash, smash and mix from multiple angles.

Embodiment 1

[0025] Take 1.75 kg of neotame, 10 kg of acesulfame potassium, 40 kg of erythritol and 11.2 kg of maltitol and put them into the multidimensional mixer, control the number of stages of the multidimensional mixer to 800rpm, and mix for 20 minutes;

[0026] Then drop into 1.5 kilograms of 2-(4-methoxyphenoxy)-sodium propionate, 1.8 kilograms of beta-cyclodextrin, 0.2 kilograms of carboxymethyl cellulose and remaining 33.55 kilograms of maltitol in this mixed material, control The number of stages of the multi-dimensional mixer is 1000rpm. After mixing for 40 minutes, the material is discharged and packed into bags to obtain the compound sweetener product.

Embodiment 2

[0028] Take 1.875 kg of neotame, 15 kg of acesulfame potassium, 38.8 kg of erythritol and 10 kg of maltitol and put them into the multidimensional mixer, control the number of stages of the multidimensional mixer to 800rpm, and mix for 20 minutes;

[0029] Drop into 1.725 kilograms of 2-(4-methoxyphenoxy)-sodium propionate, 2.2 kilograms of beta-cyclodextrin, 0.4 kilograms of carboxymethylcellulose and the remaining 30 kilograms of maltitol in this mixed material again, control The number of stages of the multi-dimensional mixer is 1000rpm. After mixing for 40 minutes, the material is discharged and packed into bags to obtain the compound sweetener product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com