Super-hydrophobic aluminum material/zinc material and preparation method and application thereof

A super-hydrophobic and water-drop technology, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., can solve the problems of high cost and complicated preparation method, and achieve low cost, simple process, and improved hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

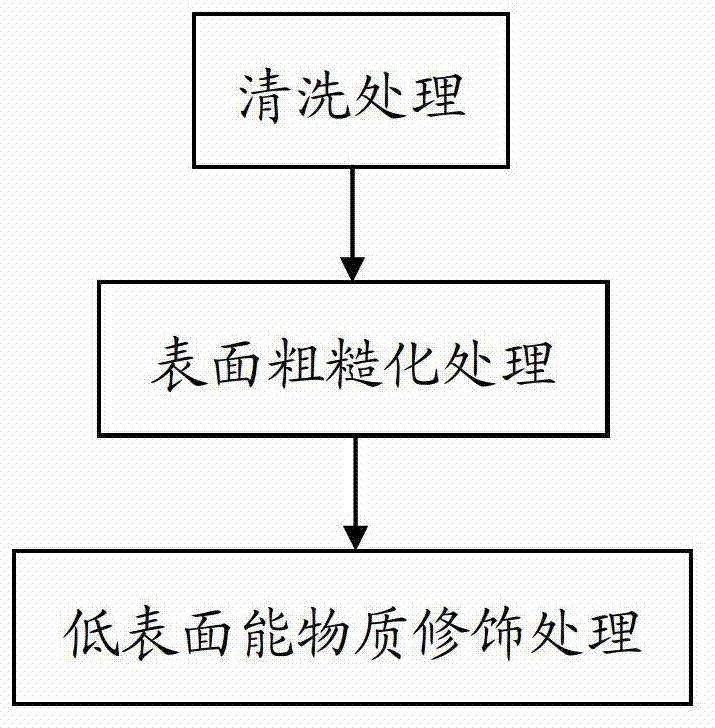

[0036] (1) Cleaning treatment: Put the aluminum material in acetone and alcohol in turn and clean it for 10 minutes under the ultrasonic power of 80W to obtain the parts to be treated;

[0037] (2) Rough surface treatment: place the piece to be treated obtained in step (1) in water at 80°C for 2 hours;

[0038] (3) Modification treatment of low surface energy substances: place the piece to be treated obtained in step (2) and the heptadecafluorodecyl trimethyltryptophan silane n-hexane solution with a volume fraction of 2% in an airtight container without direct contact. container, and the airtight container was kept at 85°C for 3h.

[0039] The characteristics of the superhydrophobic aluminum material obtained by this method are as follows:

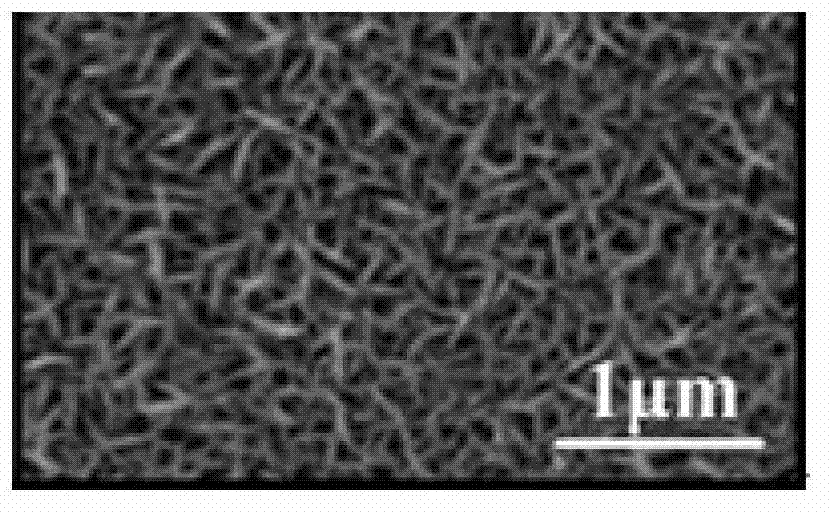

[0040] see figure 2 , as shown in the figure, the superhydrophobic aluminum material has a nano-sheet-like silk leaf-like surface structure, and the above-mentioned structure makes its surface have a higher roughness;

[0041] see F...

Embodiment 2

[0043] (1) Cleaning treatment: Put the zinc material in acetone and alcohol in turn and clean it under 80W ultrasonic waves for 10 minutes to obtain the parts to be treated;

[0044] (2) Rough surface treatment: place the piece to be treated obtained in step (1) in water at 90°C for 3 hours;

[0045] (3) Modification treatment of low surface energy substances: place the piece to be treated obtained in step (2) and the heptadecafluorodecyl trimethyltryptophan silane n-hexane solution with a volume fraction of 2% in an airtight container without direct contact. container, and the airtight container was kept at 85°C for 3h.

[0046] The characteristics of the superhydrophobic zinc material obtained by this method are as follows:

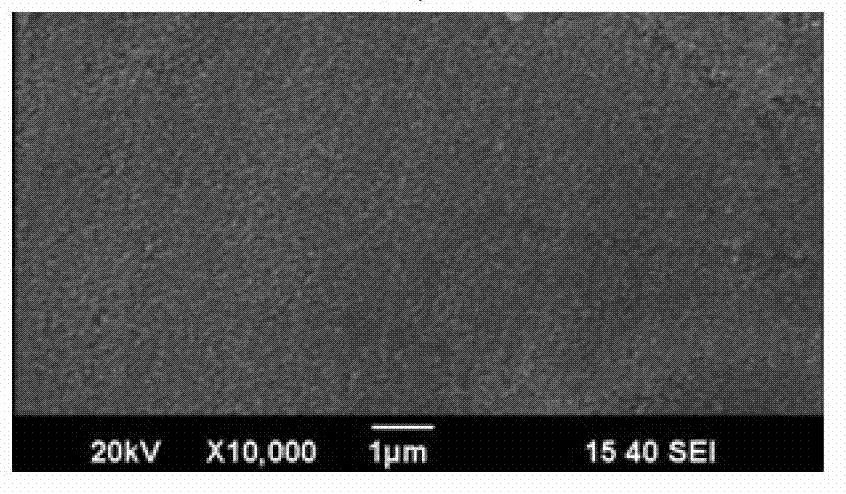

[0047] see image 3 , as shown in the figure, the superhydrophobic zinc material has a nanoscale surface structure of dense rough protrusions;

[0048] see Figure 5 , as shown in the figure, the contact angle of water droplets on the surface of super...

Embodiment 3

[0050] (1) Cleaning treatment: Put the aluminum material in acetone and alcohol in turn, and clean it under 60W ultrasonic waves for 20 minutes to obtain the parts to be treated;

[0051] (2) Rough surface treatment: place the piece to be treated obtained in step (1) in water at 90°C for 3 hours;

[0052] (3) Modification treatment of low surface energy substances: immerse the piece to be treated obtained in step (2) in an alcohol solution of 0.01 mol / L n-octadecylmercaptan for 4 hours.

[0053] The characteristics of the superhydrophobic aluminum material obtained by this method are as follows:

[0054] Has a surface structure of nano-flaky filaments;

[0055] The contact angle of water droplets on the surface of the superhydrophobic aluminum material is greater than 160°, and the rolling angle is less than 5°, which has a superhydrophobic state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com