Harmless treatment and resource recovery method and harmless treatment and resource recovery equipment for waste circuit board with components

A waste circuit board, harmless treatment technology, applied in the direction of electronic waste recycling, recycling technology, solid waste removal, etc., to achieve the effects of increased production efficiency, low energy consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

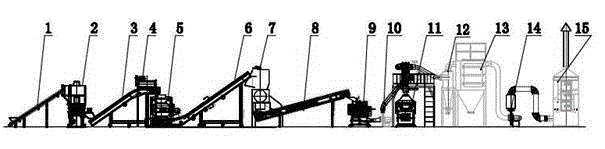

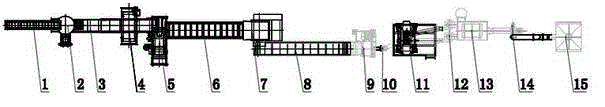

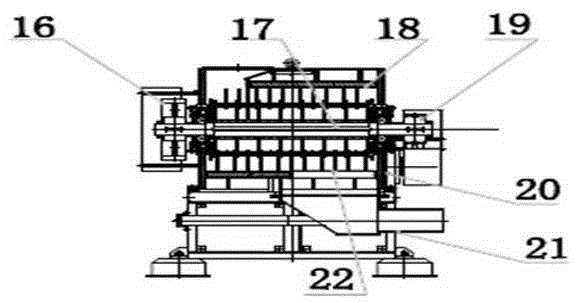

[0047] The method for harmless treatment and resource recovery of waste circuit boards with components and parts of the present invention is as follows:

[0048] 1) The waste circuit board with components is added to the primary conveyor belt, and under the traction of the conveyor belt motor, it enters the primary crusher. Through the collision and rubbing movement in the crusher, the components on the circuit board can be recovered. Fully dissociate and break the circuit board into small pieces;

[0049] 2) The mixture of broken small circuit boards and components falls from the outlet of the primary crusher to the secondary conveyor belt; these mixtures contain iron, copper, aluminum and circuit boards;

[0050] 3) A suspended magnetic separator is installed on the secondary conveyor belt, when these mixtures pass through the magnetic separator, iron is separated from the mixture;

[0051] 4) The mixture after separating the iron is evenly distributed to the belt of the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com