A high-efficiency lithium-ion battery cathode electrode recycling system

A technology of lithium ion battery and positive pole piece, which is applied in the field of high-efficiency lithium ion battery positive pole piece recycling system, can solve the threat of living environment, waste of resources, and cannot achieve high-purity recovery of finished aluminum powder and positive black powder, etc. problem, to achieve the effect of high processing efficiency, resource saving and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

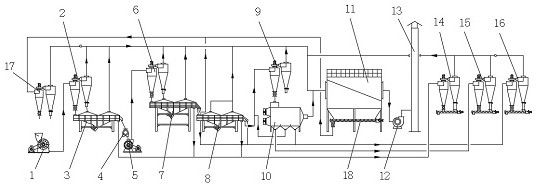

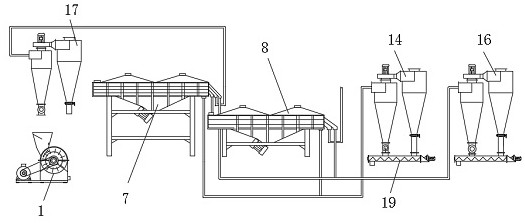

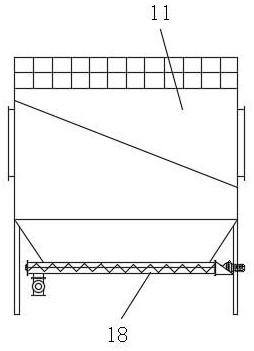

[0018] see Figure 1-4 , The present invention provides a technical solution: a high-efficiency lithium-ion battery positive pole piece recycling system, including a pulverizer 1, a primary vibrating screen 3, a refiner 5, a secondary vibrating screen 7, and a tertiary vibrating screen 8 , the air separator 10, the chimney 13, the collector one 14, the collector two 15 and the collector three 16, the first-stage vibrating screen 3, the second-stage vibrating screen 7 and the third-stage vibrating screen 8 are respectively provided with a layer of screen mesh , three-layer screen mesh and two-layer screen mesh, and the ends of the first-stage vibrating screen 3, the second-stage vibrating screen 7 and the third-stage vibrating screen 8 are located at the positions corresponding to their screen meshes and the bottom of the screen box from top to bottom. One discharge port, four discharge ports and three discharge ports; the first Shakeron dust collector 2 is connected through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com