Ammonia recovering process for liquid ammonia collator

A technology of liquid ammonia finishing and machine matching ammonia, which is applied to textiles and papermaking, fabric surface trimming, etc., and can solve problems such as huge equipment, large investment, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

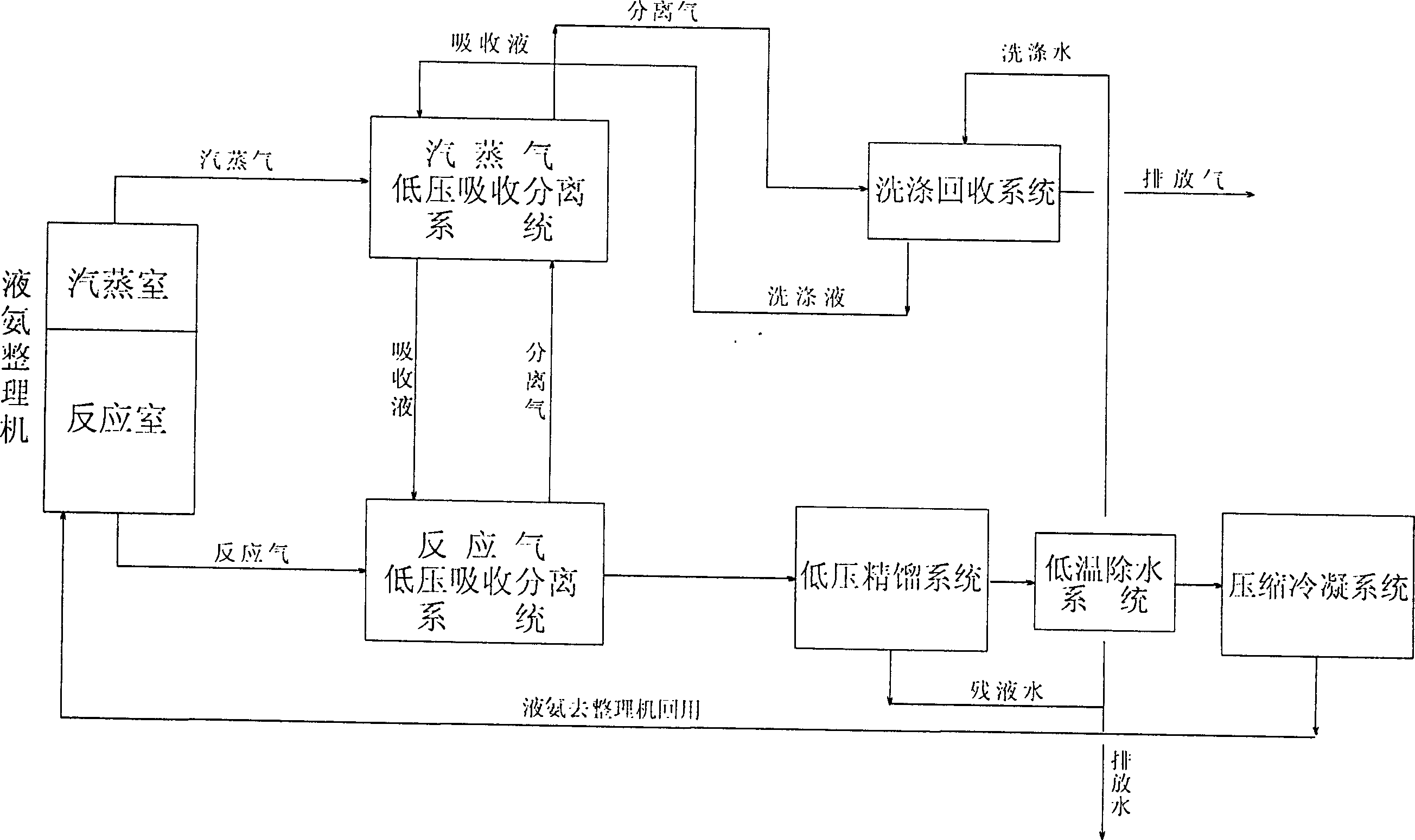

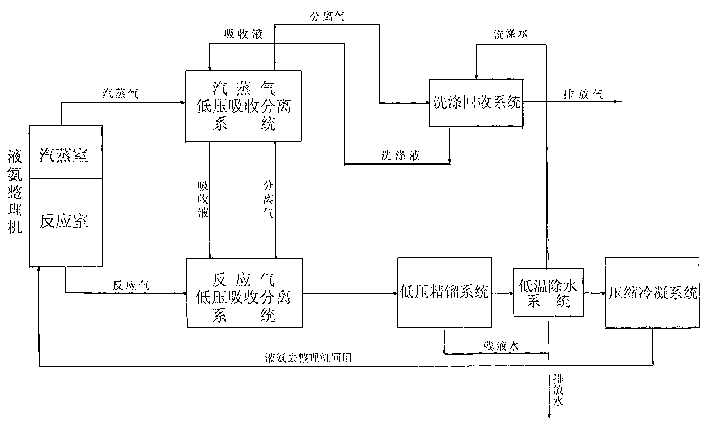

[0016] like figure 1 Shown: The mixed gas with ammonia, air and water vapor escaped from the reaction chamber and the steaming chamber of the liquid ammonia finishing machine respectively, the former is the reaction gas, and the latter is the steam.

[0017] Ammonia process: The reaction gas is absorbed by the reaction gas low pressure absorption and separation system, and the ammonia gas is absorbed to make a certain concentration of ammonia water. The ammonia water goes to the low pressure rectification system for rectification to obtain high concentration ammonia gas. The ammonia gas is dewatered by the low temperature water removal system and then compressed and condensed into the liquid ammonia. The liquid ammonia is sent back to the finishing machine for recycling.

[0018] The steam and steam are cooled and absorbed by the steam-vapor low-pressure absorption a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com