Continuous lithium alkylide production system

A production system, technology of alkyllithium, applied in the direction of lithium organic compounds, etc., can solve problems such as large and unusable alkyllithium equipment, hidden safety hazards in the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

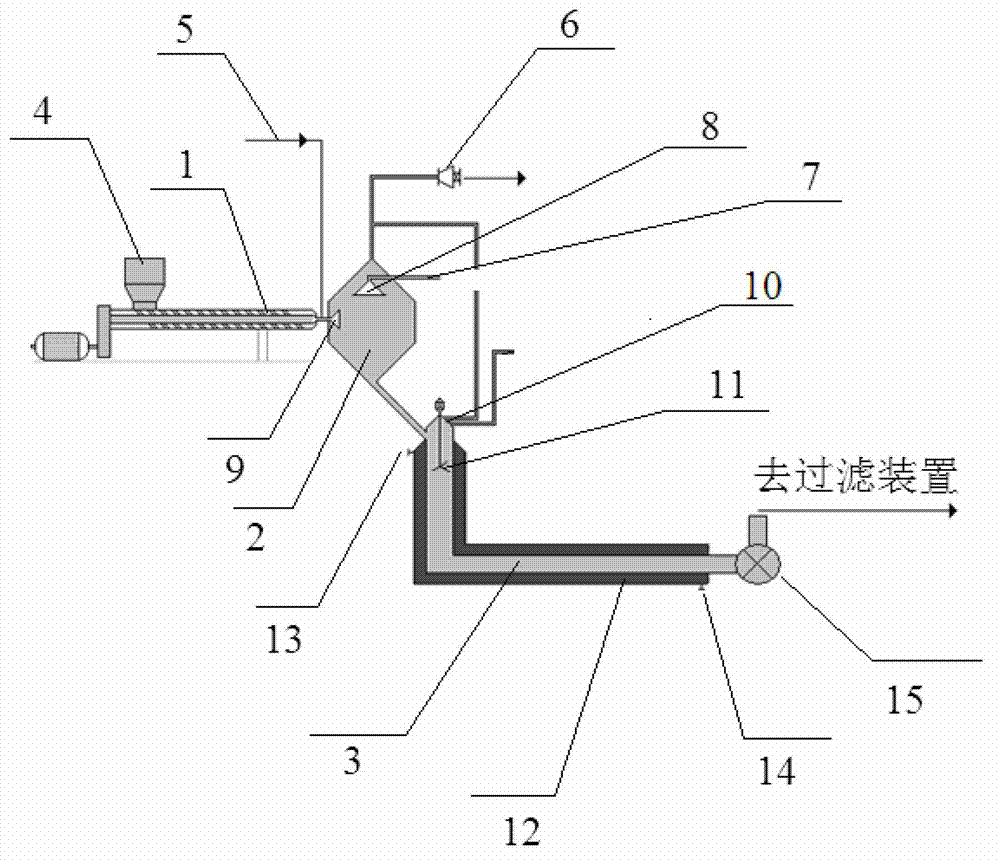

[0018] A sort of figure 1 The continuous production system of alkyllithium shown includes a twin-screw extruder 1, a mixer 2, a metal lithium nozzle 9 located in the mixer 2, a solvent nozzle 8, and an L-shaped reactor 3; one end of the metal lithium nozzle 9 is connected to a double The screw extruder 1 is communicated, the solvent nozzle 8 is connected to the solvent storage device through the solvent supply pipeline 7; the top of the L-shaped reactor 3 is connected to the bottom of the mixer 2 through a pipeline, and a haloalkyl dripping port 10 is provided on the top.

[0019] The twin-screw extruder 1 is equipped with an automatic feeder 4 for adding lithium sticks. The metal lithium nozzle 9 communicates with the argon gas supply channel 5 . The block metal lithium is machine-cut and then enters the hot-melt screw for extrusion and is supplemented with argon gas at constant pressure. Through pressure spray, the molten lithium is sprayed into the mixer in the form of mis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com