Method for manufacturing wall surface treatment agent

A technology of surface treatment agent and manufacturing method, which is applied in the direction of wax paint, etc., to achieve the effect of outstanding efficacy, good effect and saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

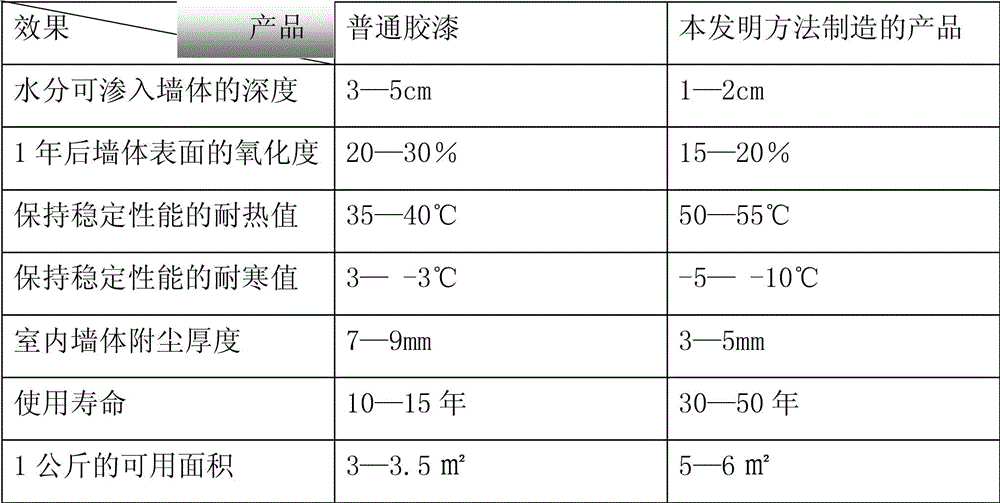

Image

Examples

Embodiment 1

[0018] Weigh each component and get the raw materials ready in the following parts by weight:

[0019] 40 parts of paraffin, 280 parts of diesel oil, 140 parts of gasoline, 0.5 parts of sodium chloride, 180 parts of methyl amyl ketone, and some spare water.

[0020] Step 1: Heat the paraffin to a molten state, control the temperature at 50°C-75°C, then add sodium chloride to the obtained paraffin liquid, stir evenly, and heat to 240°C, add diesel oil at this temperature, and stir thoroughly.

[0021] Step 2: Cool down the temperature obtained in Step 1 to 60°C, add gasoline and stir evenly, then add methylpentanone, and stir to fully dissolve it, cool down to 50°C, add water and stir evenly.

[0022] Step 3: After cooling the obtained product in Step 2 to ambient temperature, it is miscible with the aqueous medium at a volume ratio of 1:1.

Embodiment 2

[0024] Weigh each component and get the raw materials ready in the following parts by weight:

[0025] 50 parts of paraffin, 300 parts of diesel oil, 150 parts of gasoline, 1 part of sodium chloride, 200 parts of methyl amyl ketone, and some spare water.

[0026] Step 1: Heat the paraffin to a molten state, control the temperature at 80°C-120°C, then add sodium chloride to the obtained paraffin liquid, stir evenly, and heat to 250°C, add diesel oil at this temperature, and stir thoroughly.

[0027] Step 2: Cool down the temperature obtained in Step 1 to 70°C, add gasoline and stir evenly, then add methylpentanone, and stir to fully dissolve it, cool down to 55°C, add water and stir evenly.

[0028] Step 3: After cooling the obtained product in Step 2 to ambient temperature, it is miscible with the aqueous medium at a volume ratio of 1:1.

Embodiment 3

[0030] Weigh each component and get the raw materials ready in the following parts by weight:

[0031] 60 parts of paraffin, 320 parts of diesel oil, 160 parts of gasoline, 1.5 parts of sodium chloride, 220 parts of methyl amyl ketone, and some spare water.

[0032] Step 1: Heat the paraffin to a molten state, control the temperature at 130°C-170°C, then add sodium chloride to the obtained paraffin liquid, stir evenly, and heat to 260°C, add diesel oil at this temperature, and stir thoroughly.

[0033] Step 2: Cool down the temperature obtained in Step 1 to 85°C, add gasoline and stir evenly, then add methylpentanone, and stir to fully dissolve it, cool down to 60°C, add water and stir evenly.

[0034] Step 3: After cooling the obtained product in Step 2 to ambient temperature, it is miscible with the aqueous medium at a volume ratio of 1:2.

[0035] The method of using the product manufactured by the method of the present invention is simple. After the product obtained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com