A kind of paper containing coffee grounds and preparation method thereof

A technology of coffee grounds and paper, which is applied in the field of papermaking, can solve the problems of destruction, waste of resources and ecological environment, and achieve the effects of protecting forest resources, enhancing the ability to eliminate odors, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

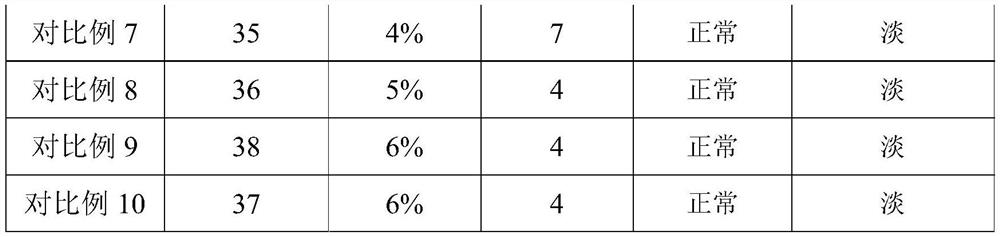

Examples

preparation example Construction

[0030] In order to solve the above problems, a second aspect of the present invention provides a method for preparing paper containing coffee grounds, comprising the following steps:

[0031] S1. Mix 5-10% of coffee grounds, 80-90% of pulp fiber and water, and obtain pulp stock solution after beating, and the beating degree is 35°-45°SR;

[0032] S2. Add 1-3% of adsorbent, 2-5% of charge regulator, and 1.5-3.5% of retention aid into water in sequence to mix and dilute to obtain a diluent, then add the obtained diluent to the pulp stock solution, stir evenly, and add water Diluted to obtain a molding slurry.

[0033] S3. The forming slurry is formed in a mold to obtain a formed paper blank, and the formed paper blank is hot-pressed to obtain a paper containing coffee grounds.

Embodiment 1

[0037] Embodiment 1 provides a paper containing coffee grounds and a preparation method thereof.

[0038] The preparation raw materials include the following components: 8kg of coffee grounds, 42.5kg of waste paper pulp fibers, 42.5kg of straw pulp fibers, 1kg of wheat flour (purchased from Guangxi Zhechuang Chemical Co., Ltd.), 0.5kg of calcium carbonate, 3kg of polydimethyldiallyl Ammonium chloride (purchased from Kunshan Shengan Biotechnology Co., Ltd., model D1UL), 2.5 kg anionic polyacrylamide (purchased from Shandong Liaocheng Longxing Environmental Protection Technology Co., Ltd., molecular weight is 12 million). Among them, the coffee grounds are coffee grounds that have been roasted at 100° C. for 1.5 hours and ground through a 150-mesh screen.

[0039] The preparation method is as follows:

[0040] S1. Mix: 8kg of coffee grounds, 42.5kg of waste paper pulp fibers, 42.5kg of straw pulp fibers and 1000kg of water, and obtain pulp stock solution after beating. The beati...

Embodiment 2

[0045] Similar to Example 1, a paper containing coffee grounds and a preparation method thereof are provided, but the preparation raw materials are: 5kg of coffee grounds, 44kg of waste paper pulp fibers, 44kg of straw pulp fibers, 1kg of wheat flour, 0.5kg of calcium carbonate, 3kg of polydicarbonate Methyldiallylammonium chloride, 2.5kg anionic polyacrylamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com