Air-permeable apped polyurethane synthetic leather and preparation method thereof

A synthetic leather and polyurethane technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problem that the air in the shoe cannot be exchanged with the outside world in time, which affects the lightness and comfort, and is prone to stuffy feet , smelly feet and other problems, to achieve the effect of light wearing shoes, good color fastness, and improved lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

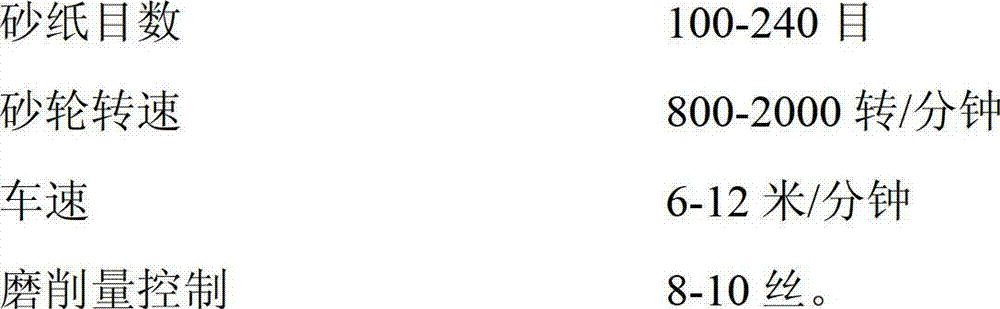

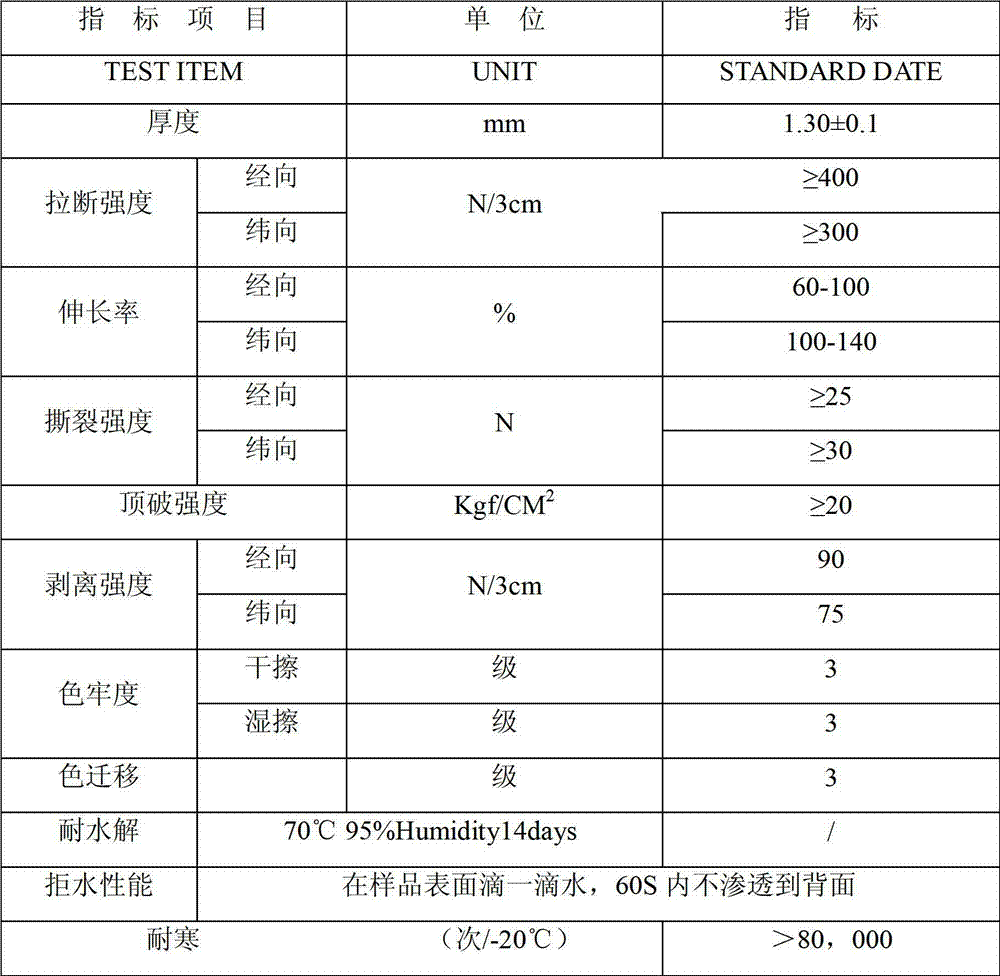

[0025] The air-permeable suede polyurethane synthetic leather of the present invention mainly undergoes three preparation processes. First, a kind of grass suede with single-sided suede is selected as the base fabric, and a layer of polyurethane slurry is coated on the suede surface, and after agglomeration A polyurethane film is formed on the surface of the base fabric, and the semi-finished product is obtained by washing to replace the solvent, drying, and shaping in sequence; then, the surface of the semi-finished product is subjected to directional grinding with sandpaper of appropriate mesh, and finally the finished product is obtained through post-processing. The specific process is as follows:

[0026] 1. Preparation of polyurethane slurry

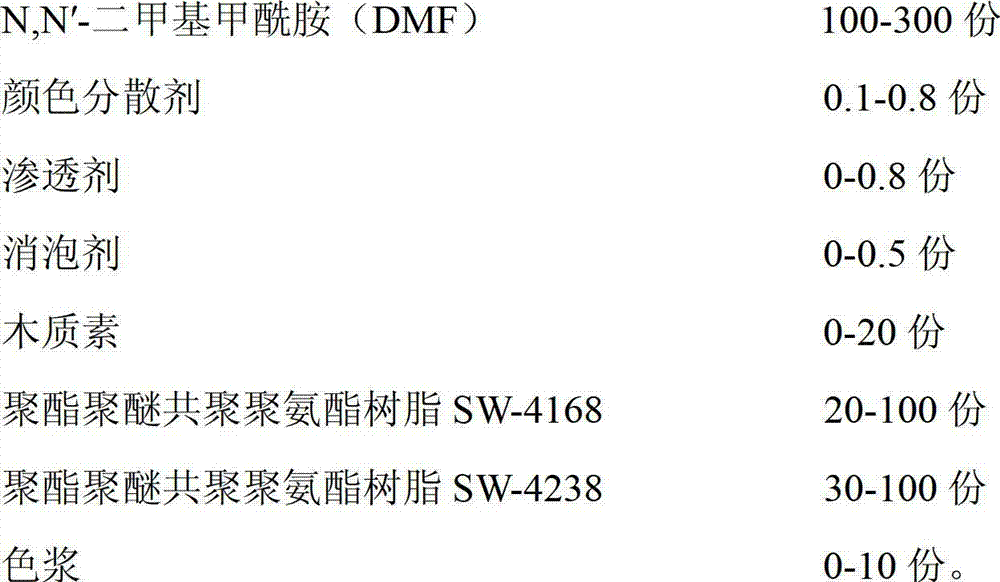

[0027] Prepared with wet synthetic leather production equipment, add 100-300 parts of solvent DMF, 0.1-0.8 parts of color dispersant BYK-104, 0-0.8 parts of penetrant BYK-6798, and defoamer OH / 60 into the wet-process batching kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com