Swing arm descending control loop of hydraulic excavator

A technology of control loop and motor arm, applied in mechanically driven excavators/dredgers, etc., can solve problems such as cost increase, energy waste, complicated control valve structure, etc., and achieve the effect of improving stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

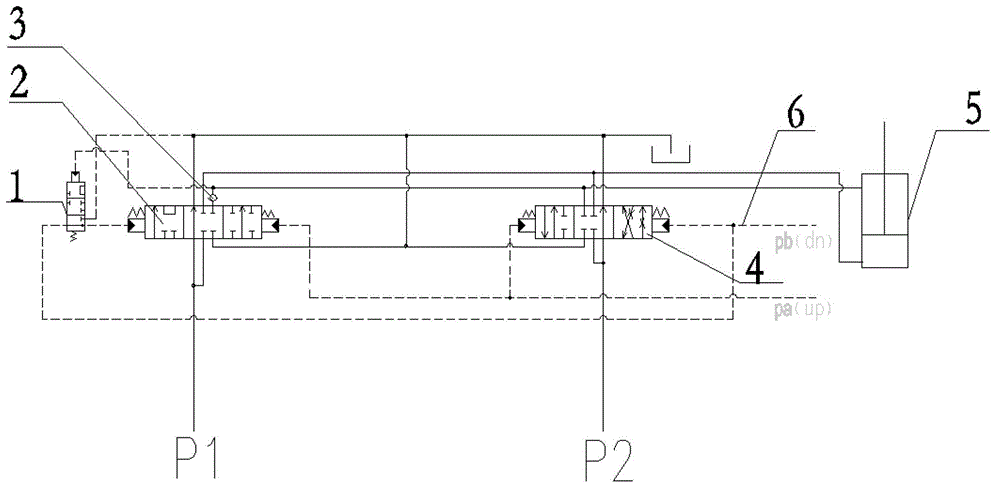

[0015] The first control valve 2 of the boom of this device is provided with a regeneration channel; the CT port of the second control valve 4 of the boom is provided with a throttle port, so that the oil return of the boom generates back pressure; There is a flow regeneration control valve 1 between the first control valve 2 of the boom, which automatically controls the on-off of the pilot signal of the first control valve 2 of the boom. The pilot signal of the flow regeneration control valve 1 is taken from the rod chamber of the boom cylinder 5, It can automatically realize the complete flow regeneration and regeneration cancellation according to the load change. During the lowering process of the boom, due to the action of the boom and the load gravity, part of the oil that originally flows back to the oil tank from the rodless chamber of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com