Digital full-intelligent ultrasonic generator and automatic frequency correcting method thereof

An ultrasonic generator technology, applied in the field of intelligent ultrasonic generators, can solve the problems of affecting product quality, reducing efficiency, and greatly affecting parts errors, so as to improve work reliability and stability, improve work efficiency, and avoid self-excited damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

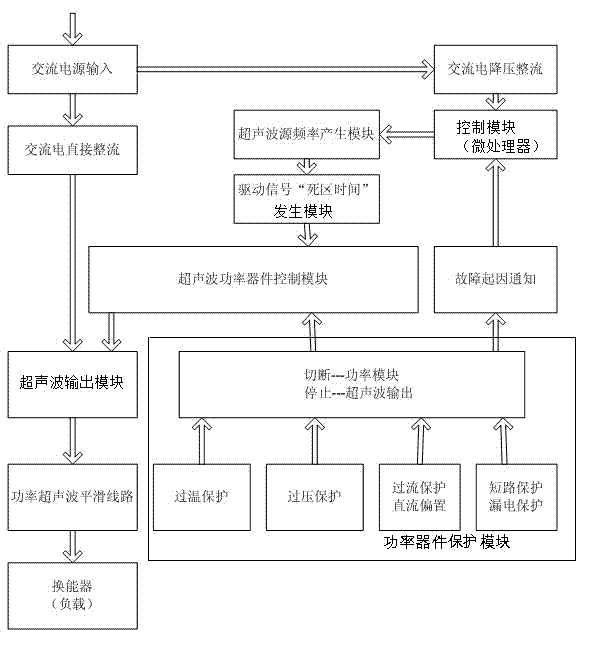

[0019] Such as figure 1 As shown, the digital fully intelligent ultrasonic generator disclosed in this embodiment includes a power supply rectification and filtering module, an ultrasonic output module and a transducer connected in sequence, and also includes a control module, an ultrasonic source frequency generation module, an ultrasonic power device control module, Power device protection module; the control module controls the ultrasonic source frequency generation module to generate the original ultrasonic frequency signal, and the original frequency signal is processed by the driving signal dead zone time generation module and then output to the ultrasonic power device control module, and then the ultrasonic power device control module Output to the ultrasonic output module. The power device protection module includes over-current protection DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com