Method and device for determining the instantaneous torque of an electronically commutated electric machine and for regulating the average torque

A motor and actual torque technology, applied in the direction of electronic commutation motor control, motor generator control, control generator, etc., can solve the problems of phase current measurement trouble and affecting motor power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

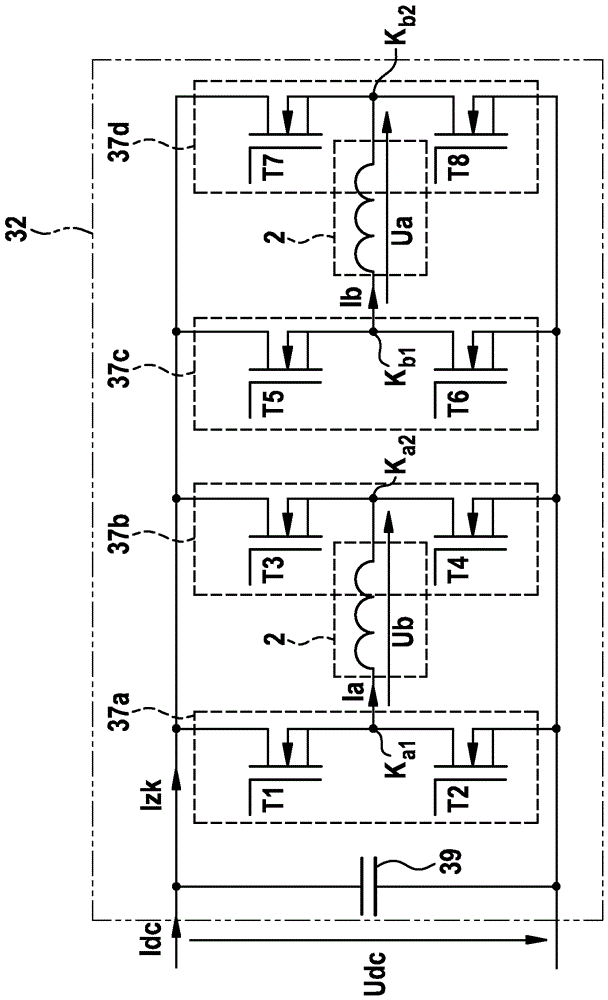

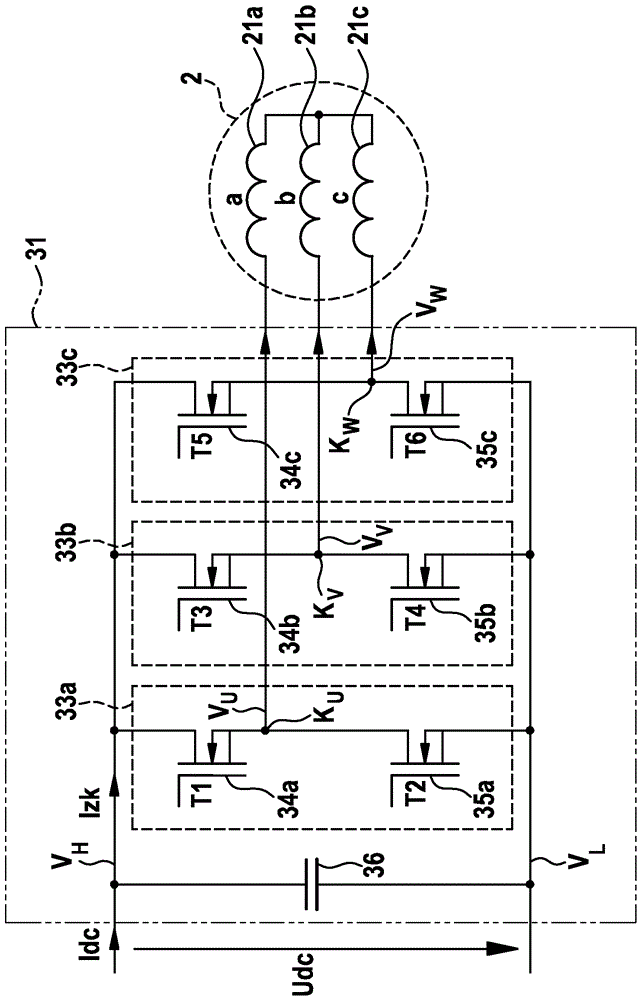

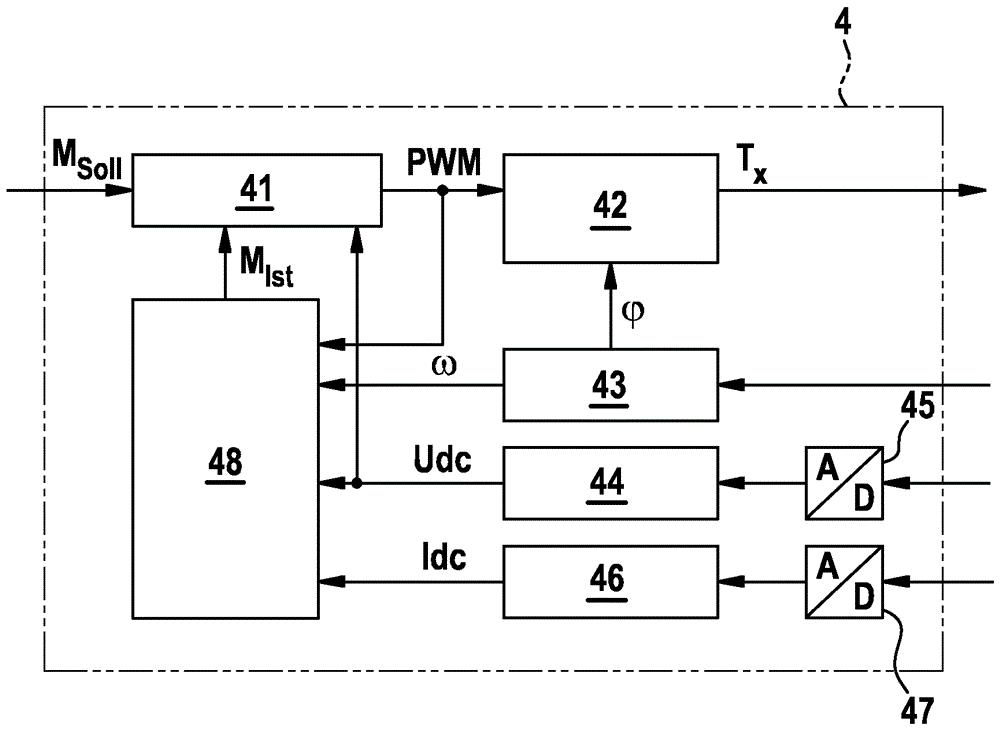

[0034] figure 1 A schematic diagram of an electric motor system 1 with an electric machine 2 which can be designed as a synchronous motor, an asynchronous motor or the like is shown. The electric motor 2 is assumed below as electric machine 2; however, it can also be a torque-driven generator. The electric motor 2 is electronically commutated, that is to say the electric motor does not have a rotor winding which must be supplied electrically from the outside, for example via a mechanical commutator or via sliding contacts. In the case of a synchronous motor, the rotor is provided with permanent magnets, which form the rotor poles to provide the excitation magnetic field. Furthermore, a plurality of phase strings are provided on the respective stator, which phase strings are actuated by applying phase voltages or phase potentials in order to generate a magnetic field in a direction dependent on a voltage vector determined by the phase voltages. This magnetic field is generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com