Method for preparing betamethasone dipropionate atomization inhalant

A technology of betamethasone dipropionate and atomized inhalation, which is applied in the field of preparation of betamethasone dipropionate atomized inhaler, can solve the problems of unsuitability for industrialized production, long reaction time, and easy pollution of the environment, and achieve Short action time, less drug dosage, good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Control group 1: the raw material of betamethasone dipropionate was dissolved in sterilized water to obtain the first suspension.

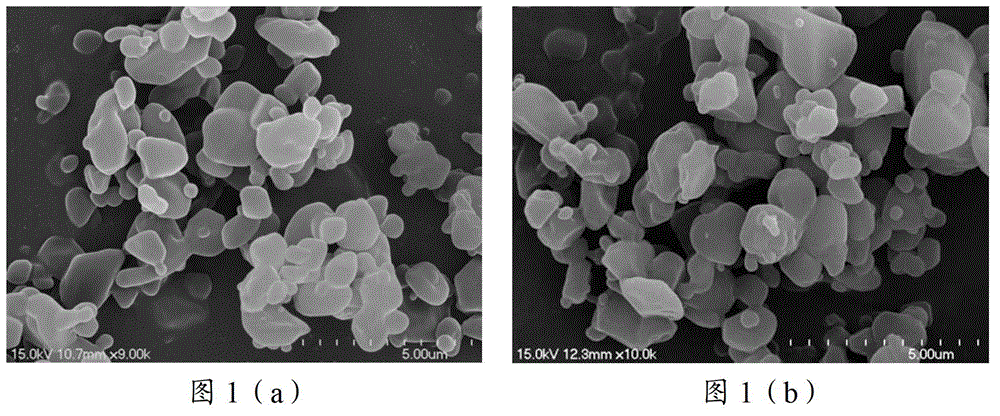

[0069] Control group 2: the first suspension was sheared at a high speed of 13,000 rpm by a disperser to obtain a second suspension.

[0070] Control group 3: Take 1 g of sodium taurocholate and dilute it 100 times with sterilized water to obtain a sodium taurocholate dilution. Take 30mL of sodium taurocholate dilution in 300mL of sterilized water, use a disperser to shear at 13,500 rpm at high speed, accurately weigh 60 mg of betamethasone dipropionate, slowly add it to the high-speed sheared sterilized water, and After shearing for 5 min, a third suspension was obtained.

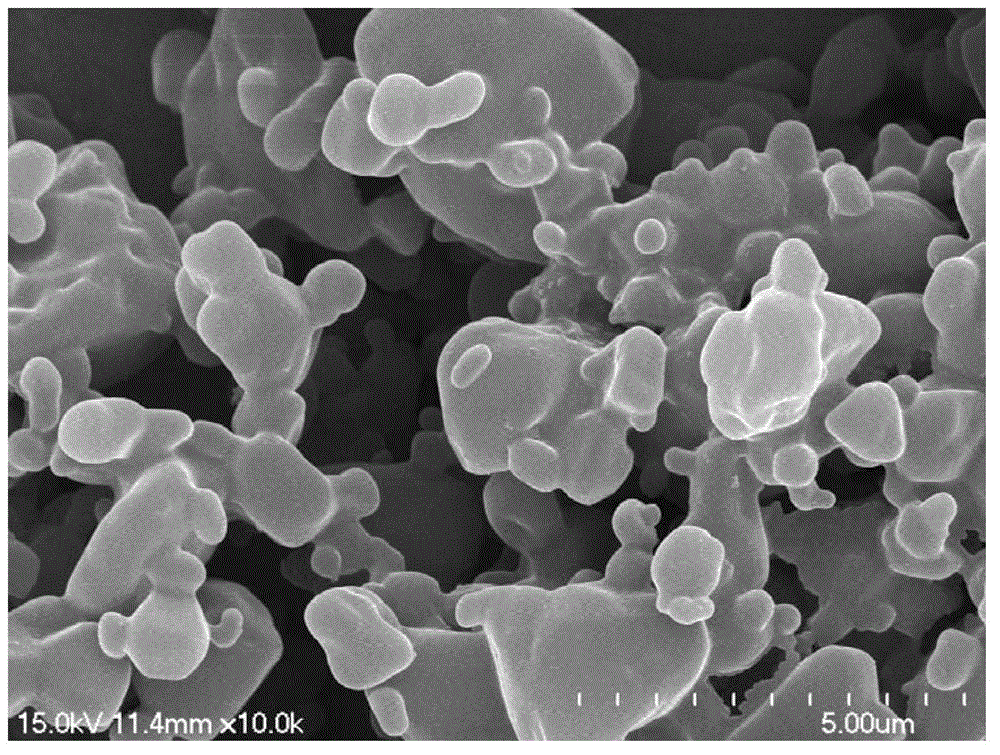

[0071] Test group: the third suspension was treated with a high-pressure micro-jet homogenizer at a pressure of 1200 bar, and circulated 3 times, 6 times, 9 times, 10 times, 20 times, and 30 times respectively to obtain the fourth suspension and the fifth suspension ,...

Embodiment 2 2

[0077] The preparation of embodiment 2 betamethasone dipropionate atomized inhalation

[0078] Take 30g of bovine serum albumin, dissolve it in 270mL of sterilized water, use a disperser to shear at 13,500 rpm at high speed, accurately weigh 81mg of betamethasone dipropionate, and slowly add it to the high-speed sheared sterilized water, High-speed shearing for 5 minutes, homogenization treatment by a high-pressure micro-fluidic homogenizer at a processing pressure of 1800 bar, 60 cycles, and filter sterilization to obtain a stable suspension of betamethasone dipropionate.

Embodiment 3 2

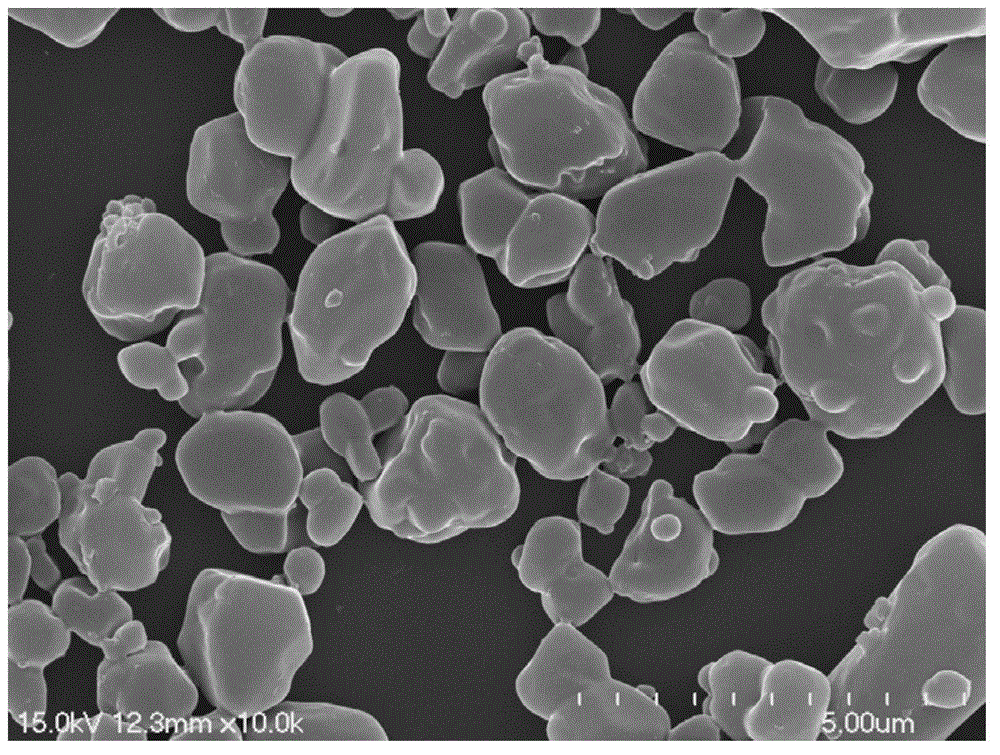

[0079] The preparation of embodiment 3 betamethasone dipropionate atomized inhalation

[0080] Take 0.5 g of Tween 80, dissolve it in 300 mL of sterilized water, use a disperser to shear at 17,000 rpm at high speed, accurately weigh 15 g of betamethasone dipropionate, and slowly add it to the high-speed sheared sterilized water, High-speed shearing for 4 minutes, homogenization treatment by a high-pressure micro-fluidic homogenizer at a processing pressure of 300 bar, 290 cycles, and filter sterilization to obtain a stable suspension of betamethasone dipropionate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com