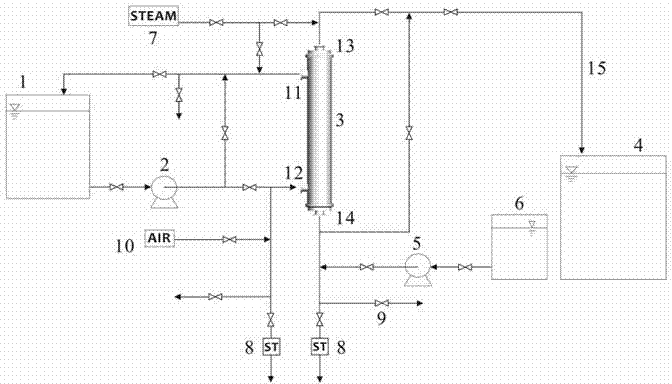

High-temperature-resistance organic film filtering system and process

A high-temperature-resistant organic membrane technology, applied in high-temperature-resistant organic membrane filtration systems and process fields, can solve unfavorable food hygiene and environmental protection problems, and achieve the effects of saving operation and maintenance costs, delaying pollution, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, soy sauce purification treatment: the processing capacity is 5 tons / hour, the temperature is 90 degrees Celsius, and the raw material liquid contains a large amount of solid insolubles such as capsicum and Chinese prickly ash, which is treated by the high temperature resistant organic membrane filtration system and process of the present invention , the filtered soy sauce is clear and bright, the sensory quality is improved, and the taste has not changed; when the organic membrane module is fouled and the transmembrane pressure difference rises, the membrane module is backwashed with hot water, and the effect is obvious. The system can at least Stable operation for one month.

Embodiment 2

[0033] Embodiment 2. Concentration and purification of tea polyphenols: the processing capacity is 6 tons / hour, and the temperature is 80 degrees centigrade. It is effectively concentrated, and there is no need to cool down the existing feed liquid during operation, the production efficiency is greatly improved, and the system can run stably for at least two months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com