Intelligent organic solid waste subcritical hydrolysis treatment energy saving system

An energy-saving system and organic solid waste technology, applied in the direction of solid waste removal, etc., can solve the problems of many uncontrollable pollution points, lengthy process flow, and low degree of automation, so as to facilitate daily maintenance and repair work, improve the working environment, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

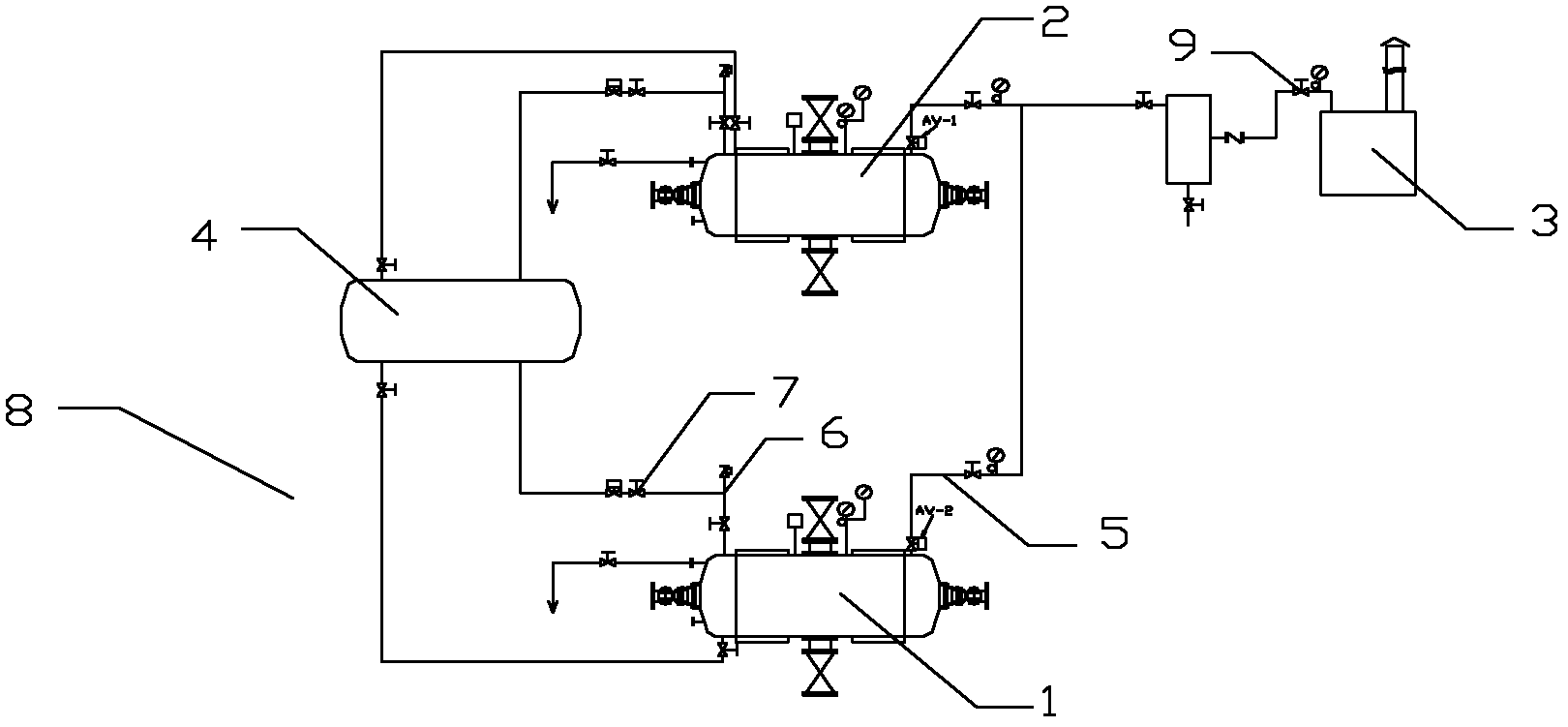

[0021] Such as figure 1 As shown, an intelligent energy-saving device for organic solid waste subcritical hydrolysis treatment, the energy-saving device includes a heating system and an energy circulation system 8, the heating system is connected to the energy circulation system 8, and also includes a heating system connected to the heating system The energy circulation system 8, the energy circulation system 8 includes A reactor 1 and B reactor 2, connecting pipelines and buffer tanks that control the alternate heating of the two reactors, and the two reactors pass through the connecting pipelines and the described Buffer connection. A reactor 1 and B reactor 2 are designed in parallel.

[0022] A reactor 1 and reactor B are used to supply heat by a steam generator 3, and a certain scale of kitchen waste is processed every day. Equipped with two reactors, maintenance work can be carried out while the system is running, and the continuous operation of the system can be maint...

Embodiment 2

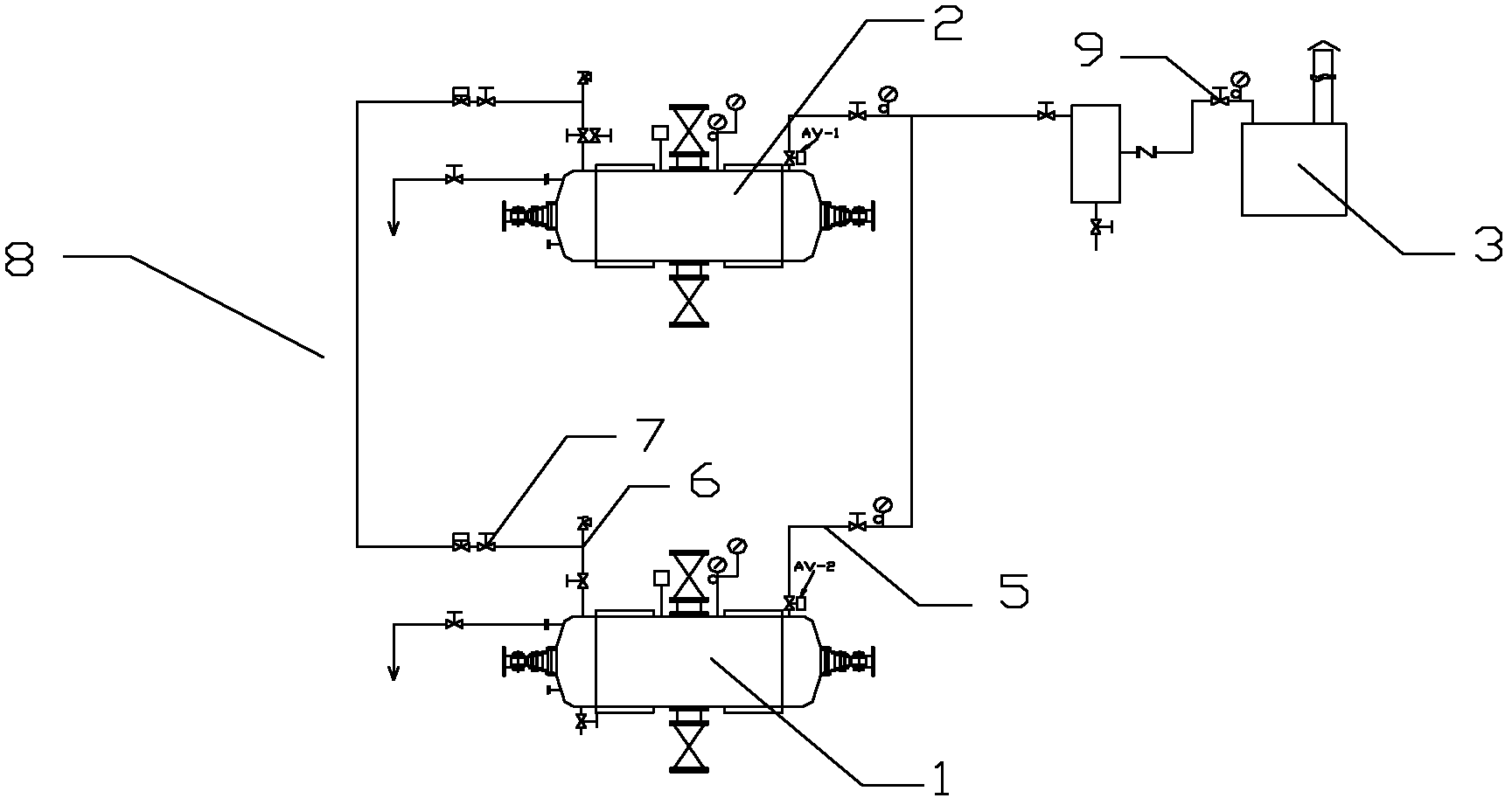

[0025] Such as figure 2As shown, reactor A 1 and reactor B 2 are used, and a steam generator 3 is used for heating, and a certain scale of kitchen waste is processed every day. The configuration of Reactor A 1 and Reactor B 2 allows maintenance work to be carried out while the system is running, maintaining continuous operation of the system to ensure production efficiency. The fully intelligent dual-reactor circulation alternate energy-saving technology collects the signal of each equipment status between multiple numerical control solenoid valves and multiple pressure detection meters, and feeds back to the PLC equipment after the signal is collected, and sends it to the central control computer according to the set An operational decision is required. After the steam generator 3 is turned on, the water will be heated to 200° C. and pressurized to a pressure of 2.0 MPa. After obtaining the status of the steam generator 3, the central control computer automatically opens t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com