A low-wastewater-emission dyeing method of wood powder for high-fastness color wood-plastic composite materials

A technology of wood-plastic composite materials and dyeing methods, which is applied in the low-wastewater-discharge dyeing field of wood powder for high-fastness color wood-plastic composite materials, and can solve the problem that the color appearance of wood-plastic products is not bright enough and affects the bonding performance of plastic and wood powder , light fastness, washing fastness and other problems, to meet the requirements of outdoor use, increase the percentage of dyeing, improve the effect of light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A low-wastewater-discharge dyeing process of wood powder for high-fastness colored plastic-wood composite materials, which comprises the following steps:

[0024] Step 1: The wood powder is grafted and modified with cationic denaturant CY-210, wherein the modification process parameters are: the dosage of cationic denaturant CY-210 is 1% owf (owf refers to the weight relative to the wood flour), Bath ratio (that is, the ratio of the weight of wood powder to the weight of water) is 1:5, treated at 95° C. for 15 minutes, and centrifuged for dehydration.

[0025] Step 2: Dye the grafted and modified wood powder with direct light fast blue BRL, the dosage of direct light fast blue BRL dye is 0.5% owf, the liquor ratio is 1:10, the dyeing temperature is 95° C., and the dyeing time is 30 min. Centrifuge to dehydrate and collect the staining residue. At the same time, test the dye concentration of the residual liquid in the initial dyeing, and convert the dyeing percentage of...

example 1

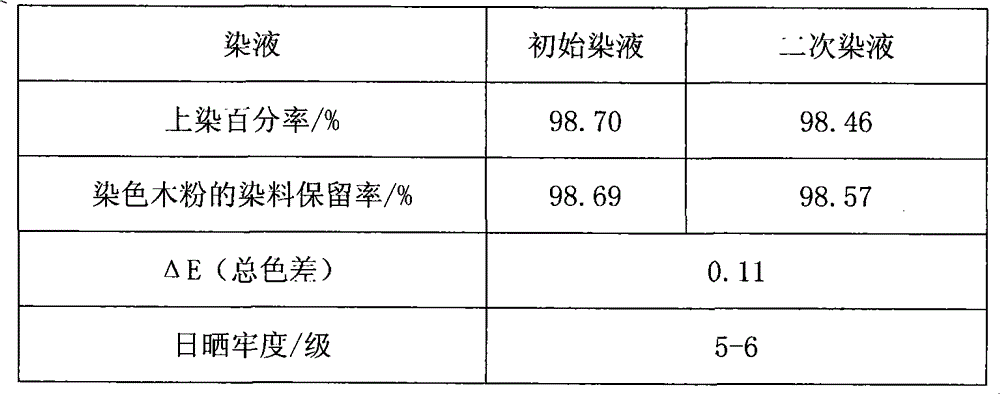

[0030] Gained each data in the example 1 is as follows table 1

[0031] Table 1

[0032]

[0033] Note: The dosage of cationic denaturant CY-210 is 1% owf, and the dosage of Direct Blue BRL is 0.5% owf

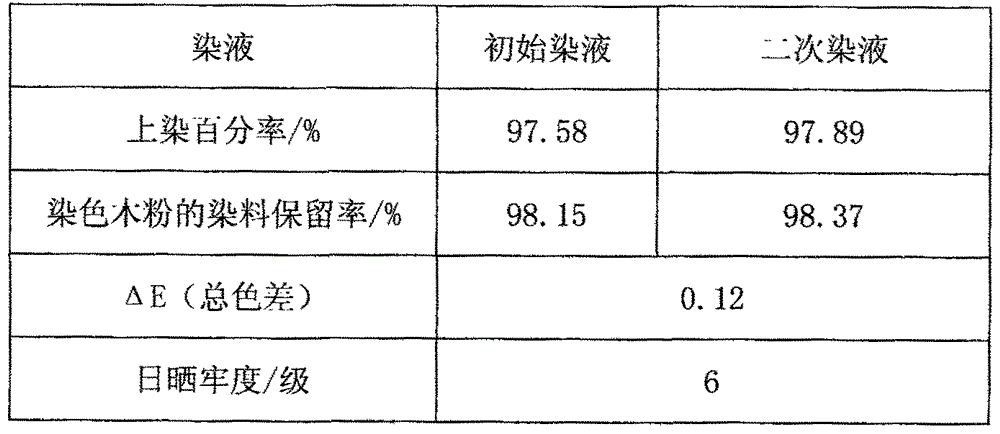

Embodiment 2

[0035] A low-wastewater-discharge dyeing process of wood powder for high-fastness colored plastic-wood composite materials, which comprises the following steps:

[0036] Step 1: Graft and modify the wood powder with Usetu TT, wherein the modification process parameters are: the amount of Usetu TT is 2% owf, the bath ratio is 1:10, treated at 80°C for 30 minutes, centrifuged dehydration.

[0037] Step 2: Dye the grafted and modified wood powder with Direct Red 4BL, the dosage of Direct Red 4BL dye is 2% owf, the bath ratio is 1:10, the dyeing temperature is 80° C., and the dyeing time is 30 minutes. Centrifuge to dehydrate and collect the staining residue. At the same time, test the dye concentration of the residual liquid in the initial dyeing, and convert the dyeing percentage of Direct Fast Red 4BL dye.

[0038] Step 3: Wash the dyed and dehydrated wood flour once with hot water. The washing process parameters are: bath ratio 1:10, temperature 95°C, time 10min, then centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com