Device and method for rapidly producing oxygen

An oxygen and fast technology, applied in the direction of oxygen preparation, etc., can solve the problems of many reagents, difficult to control, complex structure, etc., and achieve the effects of low production cost, convenient portability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

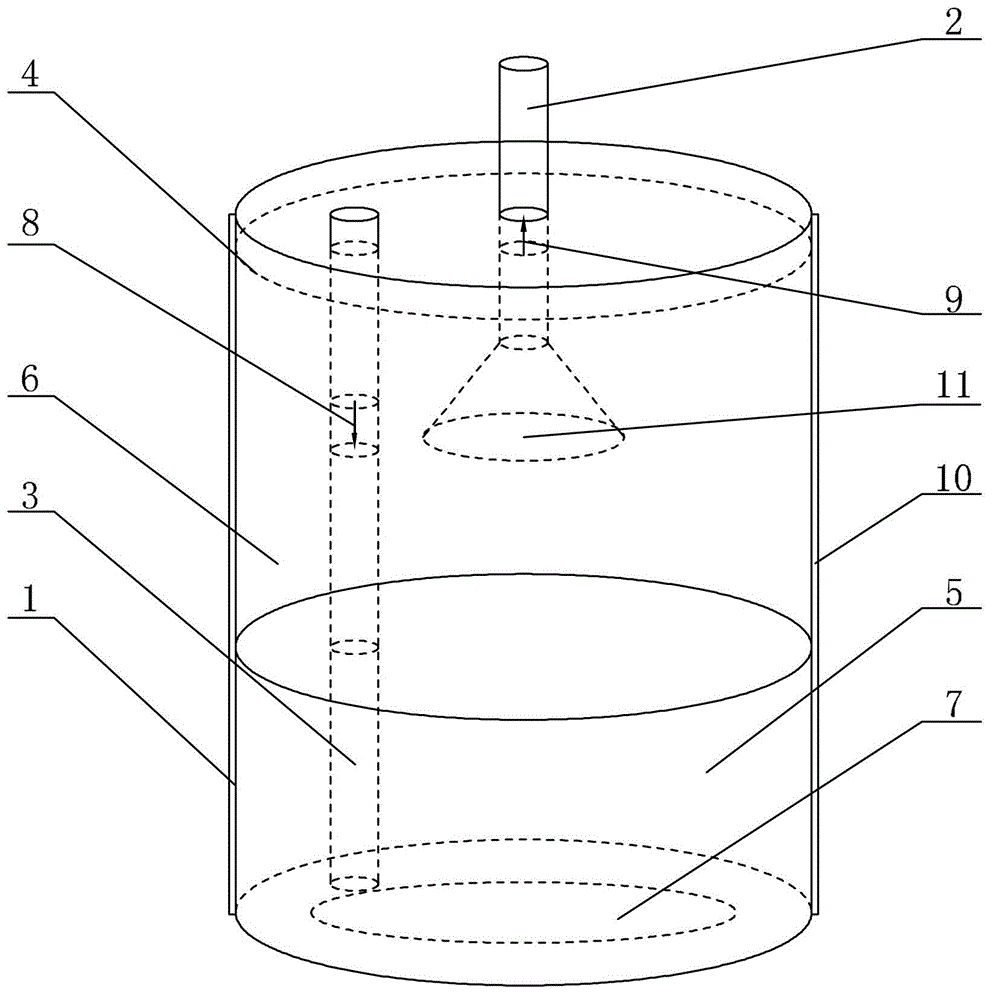

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a device for rapidly generating oxygen described in this embodiment includes a container 1, an oxygen outlet tube 2, an initiation tube 3, a molecular sieve 4, and an oxygen-producing reactant 5, and the oxygen-producing reactant 5 is placed in the container 1, The molecular sieve 4 is arranged at the opening of the container 1, the molecular sieve 4 and the container 1 form a reaction chamber 6, the lower end of the initiation tube 3 is inserted into the oxygen-producing reactant 5, and the upper end of the initiation pipe 3 passes through the molecular sieve 4 and is exposed outside the reaction chamber 6 , the lower end of the oxygen outlet pipe 2 passes through the molecular sieve 4 and is inserted in the reaction chamber 6, and the lower end of the oxygen outlet pipe 2 is located above the oxygen production reactant 5, and the oxygen production reactant 5 is composed of sodium superoxide, a...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the induction tube 3 of the device for rapidly generating oxygen described in this embodiment is provided with an air inlet check valve 8 , and the oxygen outlet pipe 2 is provided with an outlet check valve 9 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a heat insulating jacket 10 is set on the outer wall of the container 1 of a device for rapidly generating oxygen in this embodiment.

[0022] In this embodiment, the heat insulation cover 10 prevents the heat generated by the chemical reaction from scalding the oxygen inhaler.

[0023] Other components and connections are the same as those in the first embodiment.

[0024] Specific implementation mode four: combination figure 1 To illustrate this embodiment, a heating zone 7 is provided at the bottom of the container 1 of a device for rapidly generating oxygen described in this embodiment.

[0025] Personnel who need oxygen supply can trigger the reaction of oxygen-generating reactants 5 through heating zone 7 to generate oxygen by lighters or matches and other igniters.

[0026] Other components and connections are the same as those in the first embodiment.

[0027] Specific im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com